When it comes to the fascinating world of chemistry, one of the most intriguing phenomena is solid-state diffusion. This process, which involves the movement of atoms or molecules within a solid material, plays a crucial role in various scientific and technological applications. From enhancing the durability of materials to enabling the production of advanced electronic devices, solid-state diffusion offers a multitude of advantages.

In this article, we will explore 10 astonishing facts about solid-state diffusion that highlight its importance and complexity. So, buckle up and get ready to delve into the world of atoms and molecules as we uncover some mind-boggling details about this captivating process.

Key Takeaways:

- Solid-state diffusion is the movement of atoms through solid materials, influencing properties like strength and conductivity. It’s crucial in making alloys and even in manufacturing electronic components.

- Understanding solid-state diffusion helps improve energy storage technologies like lithium-ion batteries, making them more efficient and long-lasting. It’s like a secret ingredient for better batteries!

Solid-state diffusion is a fundamental process in materials science.

Solid-state diffusion refers to the movement of atoms or molecules through a solid material, driven by temperature and concentration gradients. It plays a crucial role in various fields, including metallurgy, semiconductors, and ceramics.

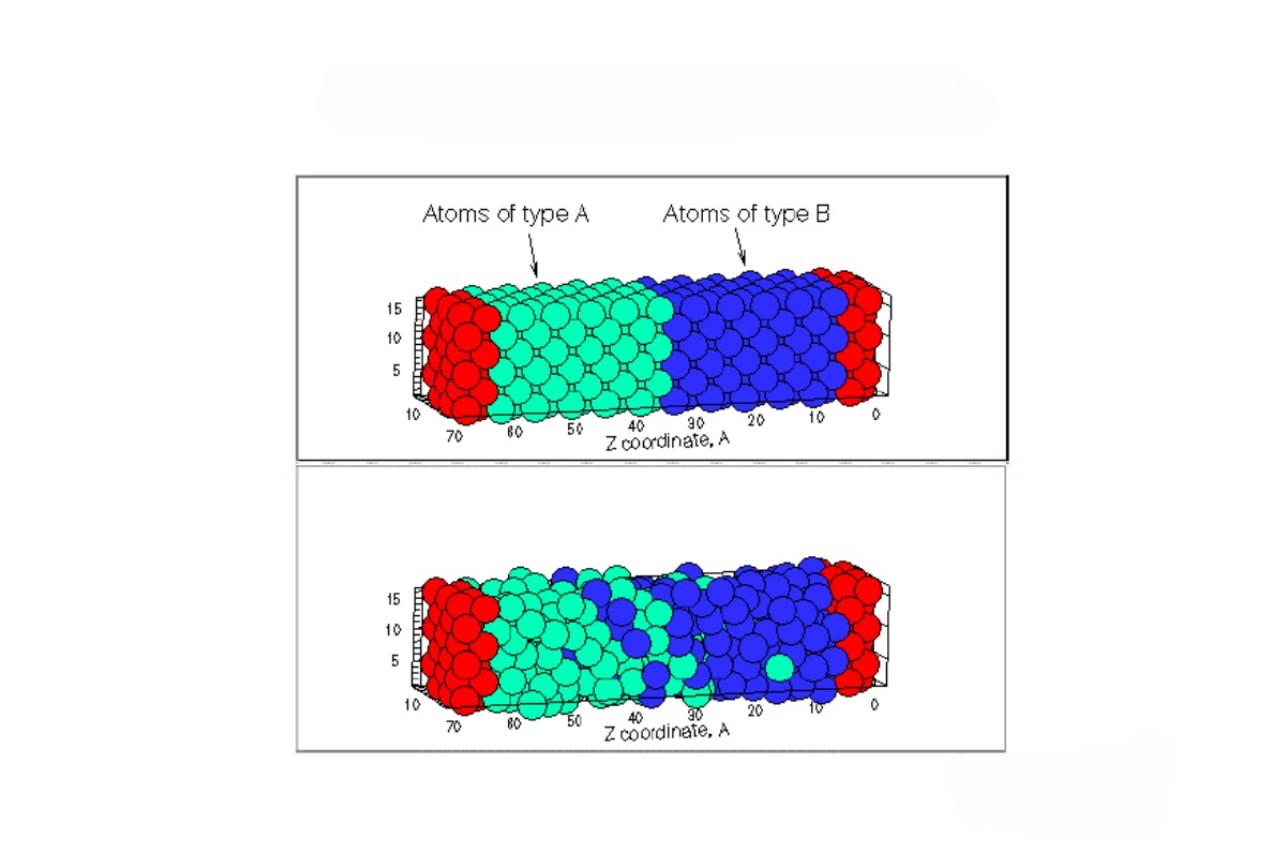

Diffusion in solids occurs through lattice defects.

During solid-state diffusion, atoms diffuse through the lattice structure of the material. This diffusion can occur through point defects such as vacancies or interstitial sites, as well as through extended defects like grain boundaries or dislocations.

Different factors influence the rate of solid-state diffusion.

The rate of solid-state diffusion is influenced by various factors including temperature, diffusion distance, concentration gradient, crystal structure, and the presence of impurities. These factors can significantly affect the diffusion kinetics and the resulting material properties.

Solid-state diffusion can lead to structural changes in materials.

As atoms move through a solid lattice during diffusion, they can rearrange and cause structural transformations in the material. This can result in changes in physical, mechanical, or electrical properties, making solid-state diffusion an essential process for materials engineering.

Solid-state diffusion is crucial in the formation of alloys.

Alloying involves the diffusion of different elements into a solid matrix, resulting in the formation of new material properties. Solid-state diffusion plays a vital role in the homogenization and mixing of the alloy constituents, leading to enhanced mechanical and chemical properties.

Solid-state diffusion is used in the manufacturing of integrated circuits.

In the semiconductor industry, solid-state diffusion is utilized to introduce dopant atoms into specific regions of a silicon wafer, creating the desired electrical properties. This process is critical for the fabrication of transistors and other electronic components.

Grain boundary diffusion affects material properties.

Grain boundaries, the interfaces between crystalline regions in a material, can also exhibit diffusion. Grain boundary diffusion can affect the mechanical strength, corrosion resistance, and electrical conductivity of materials, making it an important consideration in materials design.

Solid-state diffusion is influenced by material defects.

The presence of defects in a material, such as vacancies or dislocations, can enhance or hinder solid-state diffusion. These defects can serve as diffusion pathways or barriers, impacting the overall diffusion behavior and affecting the material’s microstructure and properties.

Solid-state diffusion can be used for surface modification.

By controlling the diffusion of certain elements onto the surface of a material, solid-state diffusion can be employed to enhance surface hardness, wear resistance, or corrosion resistance. This technique is commonly used in the production of coatings and protective layers.

Solid-state diffusion has applications in energy storage.

Through solid-state diffusion, ions can migrate through solid electrolytes, which is utilized in lithium-ion batteries, fuel cells, and other energy storage devices. Understanding and optimizing solid-state diffusion is crucial for advancing energy storage technologies.

Conclusion

In conclusion, solid-state diffusion is a fascinating area of study in chemistry that unveils a myriad of astonishing facts. From its role in various industries to the practical applications in materials science, solid-state diffusion plays a crucial role in our everyday lives. Understanding the mechanisms, factors, and limitations of diffusion in solids opens up new possibilities for innovation and advancements in technology.By exploring the properties and behavior of diffusing species in solid-state materials, scientists can design materials with enhanced properties and develop new products with improved performance. From the formation of alloys to the diffusion of dopants in semiconductors, solid-state diffusion shapes the way we approach countless technological advancements.To truly grasp the intricate nuances of solid-state diffusion, one must delve into the world of diffusion mechanisms, the factors influencing diffusion rates, and the experimental techniques used to investigate this phenomenon. By gaining a deeper understanding of solid-state diffusion, we can pave the way for future breakthroughs and push the boundaries of science and technology.

FAQs

1. What is solid-state diffusion?

Solid-state diffusion refers to the process of atomic or molecular movement within solid materials. It involves the migration of atoms or molecules through the crystalline lattice of a solid, resulting in changes in the material’s composition or properties.

2. What factors influence solid-state diffusion?

Several factors influence solid-state diffusion, including temperature, concentration gradient, crystal structure, and the presence of defects or impurities in the material. These factors can either promote or impede the diffusion process.

3. What are the practical applications of solid-state diffusion?

Solid-state diffusion has numerous practical applications. It is used in the manufacturing of alloys, heat treatment of metals, fabrication of semiconductors, production of ceramics, and diffusion-based coatings for various materials.

4. How is solid-state diffusion studied?

Scientists employ various experimental techniques to study solid-state diffusion, including diffusion couple experiments, tracer diffusion measurements, and computer simulations such as molecular dynamics. These techniques help researchers understand diffusion mechanisms and quantify diffusion rates.

5. Can solid-state diffusion be controlled?

In some cases, solid-state diffusion can be controlled by manipulating factors such as temperature, pressure, or the introduction of barrier layers. This control allows for precise alteration of material structures and properties, enabling the development of advanced materials in fields like electronics, catalysis, and energy storage.

Was this page helpful?

Our commitment to delivering trustworthy and engaging content is at the heart of what we do. Each fact on our site is contributed by real users like you, bringing a wealth of diverse insights and information. To ensure the highest standards of accuracy and reliability, our dedicated editors meticulously review each submission. This process guarantees that the facts we share are not only fascinating but also credible. Trust in our commitment to quality and authenticity as you explore and learn with us.