Polycrystalline materials are a fascinating field of study in the realm of chemistry. These materials, often comprised of multiple crystalline structures, possess unique properties and applications that are distinct from their single-crystal counterparts. From metals to ceramics, polycrystalline materials can be found in various industries, including electronics, construction, and manufacturing.

In this article, we will delve into 19 extraordinary facts about polycrystalline materials that will not only pique your interest but also provide you with a deeper understanding of their importance and impact. Whether you are a chemistry enthusiast, a materials scientist, or simply someone curious about the wonders of the natural world, get ready to explore the intriguing world of polycrystalline materials and unlock their hidden secrets.

Key Takeaways:

- Polycrystalline materials have multiple tiny crystals that make them super strong and useful in electronics, cutting tools, and even solar cells. They’re like a secret weapon in science and technology!

- These special materials can be customized for different jobs, from storing energy to making 3D-printed objects. They’re like the superheroes of the material world, with powers that help us in so many ways!

Polycrystalline materials consist of multiple crystal structures.

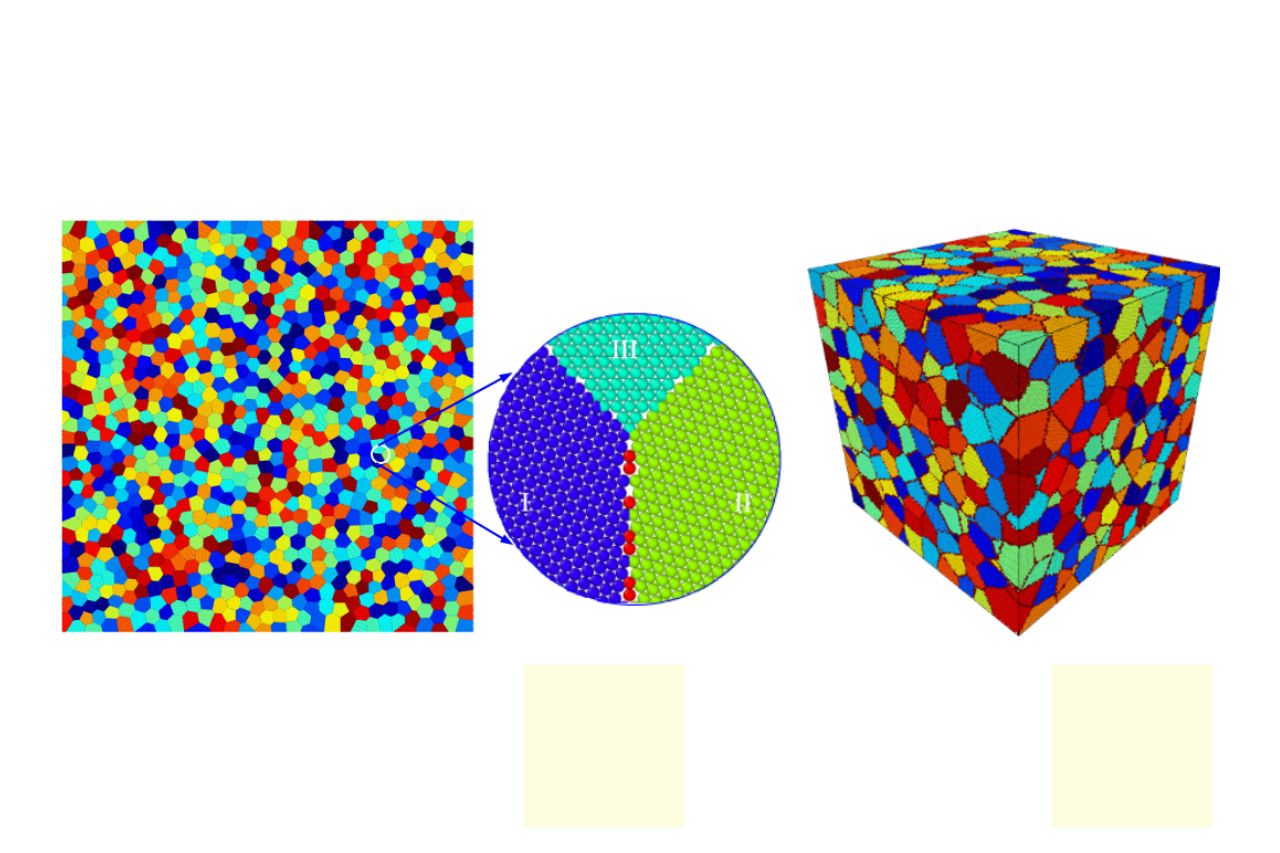

Unlike single-crystal materials, polycrystalline materials are made up of numerous small crystals. These crystals, also known as grains, are randomly oriented and form an intricate network within the material.

Polycrystalline materials exhibit enhanced mechanical strength.

The presence of multiple grains in polycrystalline materials helps reinforce their mechanical properties. The grain boundaries act as barriers to dislocation movement, making the material stronger and more resistant to deformation.

They are widely used in the manufacturing of electronic devices.

Polycrystalline materials play a crucial role in the production of electronic devices such as integrated circuits, solar cells, and light-emitting diodes (LEDs). Their unique electrical and optical properties make them ideal for these applications.

Polycrystalline materials can exhibit anisotropic properties.

Due to their random grain orientations, polycrystalline materials can display different physical properties when measured along different directions. This anisotropy can be advantageous in certain applications where specific properties need to be optimized.

They have excellent thermal conductivity.

Polycrystalline materials, particularly those made of ceramics or metals, exhibit high thermal conductivity. This makes them suitable for applications where efficient heat transfer is crucial, such as in electronic cooling systems or high-temperature environments.

Polycrystalline materials can undergo grain growth during processing.

During the fabrication process, polycrystalline materials can experience grain growth, leading to changes in their microstructure and properties. Controlling grain growth is critical in achieving the desired characteristics of the final product.

They are used in the production of hard and durable cutting tools.

Polycrystalline materials like tungsten carbide are widely employed in the manufacturing of cutting tools. Their exceptional hardness, wear resistance, and toughness make them ideal for applications that require precision cutting and shaping.

Polycrystalline materials can exhibit piezoelectric properties.

Certain polycrystalline materials, such as lead zirconate titanate (PZT), have piezoelectric properties. This means they can convert mechanical stress into electrical signals, making them valuable in sensors, actuators, and ultrasound transducers.

They are used in the construction of high-strength alloys.

The addition of polycrystalline materials in alloy compositions can improve their strength and mechanical performance. These alloys find applications in aerospace, automotive, and infrastructure industries, where high strength and durability are essential.

Polycrystalline materials can exhibit magnetic properties.

Certain polycrystalline materials, including iron-nickel alloys, can exhibit strong magnetic behavior. They are used in various applications, such as magnetic sensors, transformers, and magnetic storage devices.

They offer enhanced corrosion resistance.

Polycrystalline materials like stainless steel possess excellent corrosion resistance due to the presence of a passive oxide layer on their surface. This makes them suitable for applications involving exposure to harsh environments or corrosive substances.

Polycrystalline materials can be tailored for specific applications.

By manipulating the composition, grain size, and grain boundary characteristics, polycrystalline materials can be customized to meet the requirements of different applications. This versatility allows for the development of materials with enhanced properties.

They find applications in the field of energy storage.

Polycrystalline materials, like lithium cobalt oxide, are extensively used in rechargeable batteries and energy storage systems. Their ability to store and release energy efficiently makes them indispensable in the advancement of renewable energy technologies.

Polycrystalline materials can exhibit strain hardening behavior.

When subjected to plastic deformation, polycrystalline materials can undergo strain hardening, where their strength increases as the deformation progresses. This property is exploited in metal forming processes to enhance the mechanical properties of the final product.

They are employed in the production of advanced ceramics.

Polycrystalline materials like alumina, zirconia, and silicon carbide are widely used in the production of advanced ceramics. These ceramics exhibit superior mechanical, thermal, and electrical properties, enabling their use in diverse applications ranging from aerospace components to medical implants.

Polycrystalline materials influence the performance of solar cells.

Polycrystalline silicon is a commonly used material in the fabrication of solar cells. The arrangement of the grains affects the absorption and conversion of sunlight into electricity, ultimately influencing the efficiency of the solar cell.

They can exhibit both metallic and non-metallic properties.

Polycrystalline materials can display a wide range of properties, spanning from metallic conductivity to non-metallic characteristics like insulating or semiconducting behavior. This versatility enables their utilization in various electronic and structural applications.

They are crucial in the field of materials science research.

Polycrystalline materials serve as model systems to study the effects of grain boundaries, defects, and microstructure on material properties. Understanding their behavior contributes to the development of new materials and the advancement of materials science as a whole.

Polycrystalline materials are extensively used in additive manufacturing.

Additive manufacturing techniques, such as 3D printing, rely on polycrystalline materials to create complex and customized objects. The ability to control microstructure and produce intricate geometries makes these materials indispensable for additive manufacturing applications.

In conclusion, polycrystalline materials offer a wide range of extraordinary properties and applications. Their unique microstructure and versatility make them indispensable in various fields, including electronics, energy, engineering, and materials science. Continued research and development in this field will undoubtedly uncover even more fascinating facts and unlock new possibilities for these remarkable materials.

Conclusion

In conclusion, polycrystalline materials are truly fascinating and possess extraordinary properties that make them invaluable in various fields of science and industry. From their unique structure composed of multiple crystallites to their exceptional strength, flexibility, and electrical conductivity, these materials have revolutionized the way we understand and utilize the power of crystals.With their ability to exhibit diverse optical, thermal, and mechanical characteristics, polycrystalline materials have opened up new avenues for advancements in technology, such as solar cells, semiconductors, and superalloys. Furthermore, their applications extend to fields like aerospace, medicine, and electronics, offering endless possibilities for innovation and discovery.Understanding the properties and behaviors of polycrystalline materials allows us to harness their capabilities for a wide range of practical applications. Whether it’s improving the efficiency of solar energy conversion or developing stronger and lighter construction materials, the study of these materials continues to contribute to the advancement of science and technology.Polycrystalline materials are truly remarkable, and as our knowledge and understanding of them expand, we can expect even more extraordinary breakthroughs in the future.

FAQs

Q: What are polycrystalline materials?

A: Polycrystalline materials are solids that are composed of multiple crystallites or grains. Each individual crystallite has its own crystal structure, resulting in a material with a grainy or textured appearance.

Q: What properties do polycrystalline materials exhibit?

A: Polycrystalline materials exhibit a variety of properties depending on their composition and structure. They can have exceptional strength, flexibility, and electrical conductivity. They also possess unique optical, thermal, and mechanical characteristics.

Q: How are polycrystalline materials used in technology?

A: Polycrystalline materials are widely used in various technological applications. They are utilized in industries such as solar energy, semiconductors, aerospace, medicine, and electronics. They enable advancements in fields like energy conversion, data storage, and material engineering.

Q: How are polycrystalline materials different from single-crystal materials?

A: Single-crystal materials have a uniform crystal structure throughout, while polycrystalline materials have multiple crystallites with different orientations. This results in different properties and behaviors between the two types of materials.

Q: Can polycrystalline materials be synthesized or manufactured?

A: Yes, polycrystalline materials can be synthesized or manufactured through various methods such as solidification, precipitation, or sintering. These processes allow for the control of grain size and orientation, enabling the production of materials with specific properties and characteristics.

Was this page helpful?

Our commitment to delivering trustworthy and engaging content is at the heart of what we do. Each fact on our site is contributed by real users like you, bringing a wealth of diverse insights and information. To ensure the highest standards of accuracy and reliability, our dedicated editors meticulously review each submission. This process guarantees that the facts we share are not only fascinating but also credible. Trust in our commitment to quality and authenticity as you explore and learn with us.