Laser engravers are incredible tools that can turn ordinary materials into personalized masterpieces. Whether you're a hobbyist, a small business owner, or just curious about this technology, understanding the ins and outs of laser engraving can be both fascinating and useful. Laser engraving uses a focused beam of light to etch designs onto various surfaces like wood, metal, plastic, and even glass. This process is precise, efficient, and opens up endless creative possibilities. But how exactly does it work? What materials can you use? And what are the safety precautions? In this blog post, we'll dive into 35 intriguing facts about laser engravers that will answer these questions and more. Get ready to discover the magic behind this cutting-edge technology!

What is a Laser Engraver?

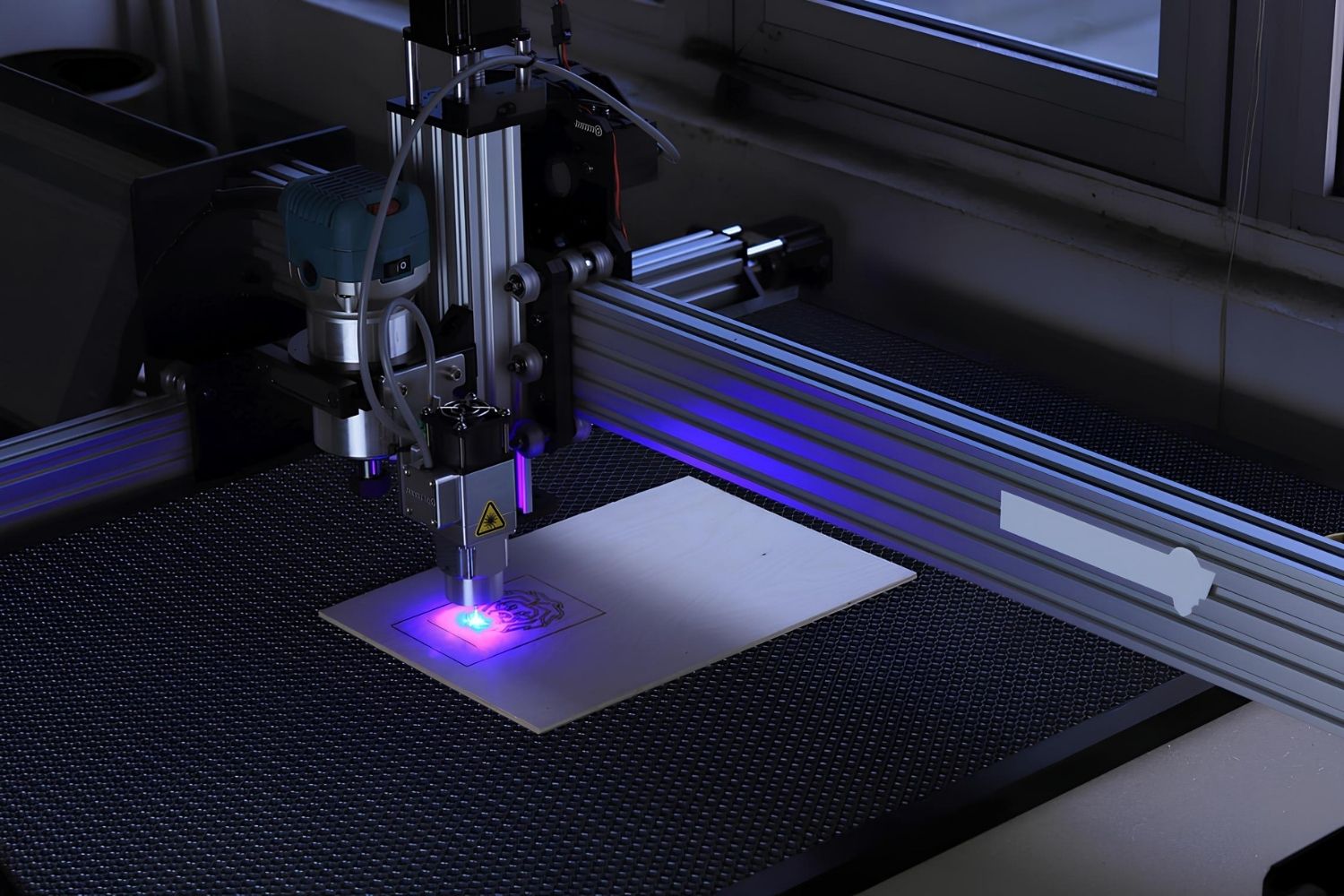

Laser engravers use focused light beams to etch designs onto various materials. These machines are popular in industries like manufacturing, art, and even personal hobbies. Here are some fascinating facts about laser engravers.

- Laser engravers can work on materials like wood, glass, metal, plastic, and leather. Each material requires different settings for optimal results.

- The technology behind laser engraving was first developed in the 1960s. It has since evolved to become more precise and efficient.

- Laser engravers use a computer to control the laser's movement. This allows for intricate and detailed designs.

- CO2 lasers are the most common type used in engraving. They are versatile and can cut through various materials.

- Fiber lasers are another type, often used for engraving metals. They offer high precision and speed.

- Laser engraving is a non-contact process. This means the laser never physically touches the material, reducing wear and tear.

- The depth of an engraving can be controlled by adjusting the laser's power and speed. This allows for both shallow etchings and deep cuts.

- Laser engravers can also be used for cutting materials. This makes them versatile tools for both engraving and cutting tasks.

- Safety is crucial when using laser engravers. Protective eyewear and proper ventilation are essential to avoid injuries and inhaling harmful fumes.

- Laser engravers can create permanent marks that are resistant to fading and wear. This makes them ideal for creating durable labels and signs.

Applications of Laser Engraving

Laser engravers have a wide range of applications. From industrial uses to personal projects, these machines offer endless possibilities.

- In the automotive industry, laser engravers are used to mark parts with serial numbers and barcodes. This helps in tracking and quality control.

- Jewelry makers use laser engravers to create intricate designs on rings, bracelets, and other pieces. This allows for personalized and unique creations.

- Laser engraving is popular in the creation of awards and trophies. It provides a professional and polished look.

- In the electronics industry, laser engravers mark circuit boards and components. This ensures proper identification and assembly.

- Artists use laser engravers to create detailed and precise artwork. This includes everything from wood carvings to glass etchings.

- Laser engravers are used in the medical field to mark surgical instruments. This helps in maintaining hygiene and tracking usage.

- Personalized gifts, such as engraved photo frames and keychains, are popular products made with laser engravers. They offer a unique and customized touch.

- Laser engraving is used in the fashion industry to create patterns on fabrics and leather. This adds a unique element to clothing and accessories.

- In the aerospace industry, laser engravers mark parts for identification and quality control. This ensures safety and reliability.

- Laser engravers are used in the production of signage. They create clear and durable signs for businesses and public spaces.

Advantages of Using Laser Engravers

Laser engravers offer several benefits over traditional engraving methods. These advantages make them a preferred choice for many applications.

- Laser engraving is faster than traditional methods. This increases productivity and reduces production time.

- The precision of laser engravers allows for intricate and detailed designs. This is difficult to achieve with manual engraving.

- Laser engravers can work on a variety of materials. This versatility makes them suitable for different industries and projects.

- The non-contact nature of laser engraving reduces wear and tear on the material. This extends the lifespan of the engraved item.

- Laser engravers produce consistent and repeatable results. This ensures high quality and uniformity in production.

- The process is environmentally friendly. Laser engraving produces less waste compared to traditional methods.

- Laser engravers can be automated. This reduces the need for manual labor and increases efficiency.

- The technology allows for easy customization. Designs can be quickly modified and applied to different items.

- Laser engraving is a clean process. It produces minimal dust and debris, making it suitable for cleanroom environments.

- The durability of laser-engraved marks makes them ideal for harsh environments. They can withstand exposure to chemicals, heat, and abrasion.

Future of Laser Engraving

The future of laser engraving looks promising. Advances in technology continue to improve the capabilities and applications of these machines.

- New laser technologies are being developed to increase speed and precision. This will make laser engravers even more efficient.

- The integration of artificial intelligence (AI) is expected to enhance design capabilities. AI can help create more complex and detailed patterns.

- Portable laser engravers are becoming more popular. These compact machines offer flexibility and convenience for on-the-go projects.

- The use of laser engravers in 3D printing is an emerging trend. This combination allows for the creation of intricate and detailed 3D objects.

- As laser engravers become more affordable, they are becoming accessible to hobbyists and small businesses. This democratizes the technology and opens up new possibilities for creativity and innovation.

The Final Cut

Laser engravers are more than just fancy tools. They’ve revolutionized how we create, design, and personalize. From intricate jewelry to detailed woodwork, these machines offer precision and versatility. They’re not just for professionals; hobbyists can dive into projects with ease. Safety is key, so always follow guidelines to protect yourself and your investment.

Understanding the different types of lasers, like CO2 and fiber, helps in choosing the right one for your needs. Maintenance is crucial for longevity, so keep your machine clean and well-tuned. The possibilities are endless, limited only by your imagination.

Whether you’re looking to start a business or just want to explore a new hobby, laser engraving opens up a world of creativity. So, get out there and start engraving your mark on the world!

Was this page helpful?

Our commitment to delivering trustworthy and engaging content is at the heart of what we do. Each fact on our site is contributed by real users like you, bringing a wealth of diverse insights and information. To ensure the highest standards of accuracy and reliability, our dedicated editors meticulously review each submission. This process guarantees that the facts we share are not only fascinating but also credible. Trust in our commitment to quality and authenticity as you explore and learn with us.