Mushet Steel revolutionized the world of metallurgy. Developed by Robert Forester Mushet in the mid-19th century, this alloy became the first self-hardening steel, meaning it could harden without quenching. This innovation significantly improved the efficiency and durability of cutting tools. Mushet Steel contains tungsten, which gives it remarkable hardness and heat resistance. It played a crucial role in the industrial revolution, enabling faster and more precise machining. This steel's unique properties made it indispensable in various industries, from railroads to manufacturing. Understanding its history and impact offers a glimpse into how one material can change the course of technological advancement.

Key Takeaways:

- Mushet Steel, invented in 1868, revolutionized manufacturing with its self-hardening and high tungsten content, impacting industries from railways to aerospace and leaving a lasting legacy in modern metallurgy.

- Despite newer materials, Mushet Steel's unique properties still find use in specialized cutting tools, historical preservation, education, custom tooling, and ongoing research for potential new applications and improvements.

What is Mushet Steel?

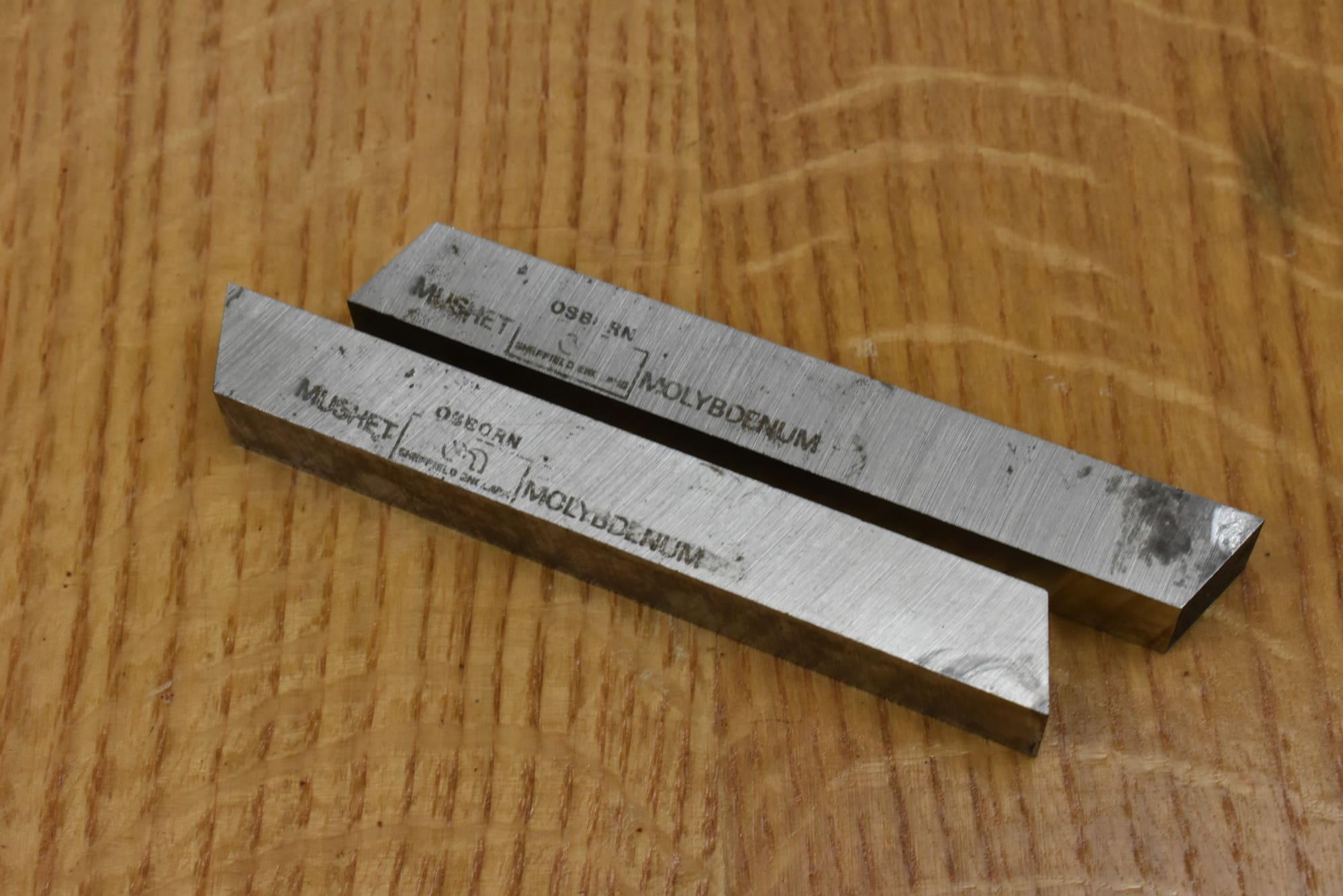

Mushet Steel, also known as R. Mushet's Special Steel (RMS), is a type of tool steel invented by Robert Forester Mushet in the mid-19th century. This revolutionary material transformed the manufacturing industry due to its unique properties.

-

Invented in 1868: Robert Forester Mushet created Mushet Steel in 1868, marking a significant advancement in metallurgy.

-

First Air-Hardening Steel: Mushet Steel was the first steel that could harden by cooling in air, eliminating the need for quenching in water or oil.

-

High Tungsten Content: It contains a high percentage of tungsten, which gives it exceptional hardness and wear resistance.

-

Self-Hardening: The steel's self-hardening property made it ideal for cutting tools, as it maintained its hardness even at high temperatures.

-

Used in Machine Tools: Mushet Steel became widely used in machine tools, significantly improving their efficiency and lifespan.

Properties of Mushet Steel

Mushet Steel's unique properties set it apart from other types of steel, making it highly valuable in various industrial applications.

-

High Red Hardness: It retains its hardness at red heat, making it suitable for high-speed cutting tools.

-

Toughness: Despite its hardness, Mushet Steel is also tough, reducing the risk of breaking or chipping during use.

-

Wear Resistance: The steel's wear resistance extends the life of tools made from it, reducing maintenance and replacement costs.

-

Heat Treatment: Unlike other steels, Mushet Steel does not require complex heat treatment processes, simplifying its use.

-

Versatility: Its unique properties make it versatile, suitable for various applications from cutting tools to dies and molds.

Historical Impact of Mushet Steel

The invention of Mushet Steel had a profound impact on the industrial revolution and the development of modern manufacturing techniques.

-

Industrial Revolution: Mushet Steel played a crucial role in the industrial revolution, enabling the creation of more efficient machinery.

-

Railway Industry: It was used extensively in the railway industry for making durable and reliable rails and switches.

-

Automotive Industry: The automotive industry benefited from Mushet Steel's durability, using it in engine components and tools.

-

Aerospace Industry: Its high-temperature resistance made it valuable in the aerospace industry for manufacturing aircraft components.

-

Tool and Die Making: The tool and die-making industry saw significant advancements due to the steel's properties, allowing for more precise and durable tools.

Innovations and Advancements

Mushet Steel spurred numerous innovations and advancements in metallurgy and manufacturing.

-

High-Speed Steel Development: Mushet Steel laid the groundwork for the development of high-speed steel, which further revolutionized tool making.

-

Improved Cutting Tools: The steel's properties led to the creation of more efficient and longer-lasting cutting tools.

-

Advancements in Metallurgy: Its invention prompted further research and development in metallurgy, leading to new steel alloys.

-

Standardization: The success of Mushet Steel contributed to the standardization of steel production processes.

-

Global Influence: Its impact was felt worldwide, influencing steel production and manufacturing practices globally.

Modern Uses of Mushet Steel

While newer materials have been developed, Mushet Steel still finds use in certain applications today.

-

Specialized Cutting Tools: It is still used for specialized cutting tools where its unique properties are advantageous.

-

Historical Preservation: Mushet Steel is studied and preserved in historical contexts to understand its impact on industrial history.

-

Educational Purposes: Metallurgy and engineering students study Mushet Steel to learn about early advancements in steel technology.

-

Custom Tooling: Custom tooling applications sometimes use Mushet Steel for its specific properties.

-

Research and Development: Ongoing research explores potential new applications and improvements to Mushet Steel.

Fun Facts about Mushet Steel

Here are some interesting tidbits about Mushet Steel that highlight its unique place in history and technology.

-

Named After Its Inventor: The steel is named after Robert Forester Mushet, who dedicated his life to improving steel production.

-

Patent Controversy: Mushet's patent for the steel led to legal battles, highlighting its significant value.

-

Museum Exhibits: Samples of Mushet Steel are displayed in museums dedicated to industrial history.

-

Literary Mentions: Mushet Steel has been mentioned in various historical and technical literature, underscoring its importance.

-

Legacy: The legacy of Mushet Steel lives on in modern metallurgy, influencing contemporary steel-making techniques.

The Legacy of Mushet Steel

Mushet Steel revolutionized the steel industry. Its unique properties made it a game-changer in tool-making and manufacturing. Known for its durability and ability to retain hardness at high temperatures, it set new standards for performance. This steel's impact extended beyond tools, influencing the development of high-speed steel and modern alloys.

Robert Forester Mushet's innovation didn't just improve tools; it paved the way for advancements in various industries. From railways to machinery, Mushet Steel's legacy is undeniable. Its introduction marked a significant leap in metallurgical science, showcasing the importance of continuous innovation.

Understanding Mushet Steel's history gives us a glimpse into the evolution of materials that shape our world today. Its story is a testament to human ingenuity and the relentless pursuit of better solutions. As we look to the future, the lessons from Mushet Steel remind us of the power of innovation in driving progress.

Frequently Asked Questions

Was this page helpful?

Our commitment to delivering trustworthy and engaging content is at the heart of what we do. Each fact on our site is contributed by real users like you, bringing a wealth of diverse insights and information. To ensure the highest standards of accuracy and reliability, our dedicated editors meticulously review each submission. This process guarantees that the facts we share are not only fascinating but also credible. Trust in our commitment to quality and authenticity as you explore and learn with us.