Saponification, the chemical process of making soap, is not only fascinating but also an essential part of our daily lives. From the moment we wake up and use soap to wash our hands or bodies, we are benefiting from the wonders of saponification. But did you know that there are extraordinary facts about this process that go beyond its basic functionality?

In this article, we will explore 13 extraordinary facts about saponification that will spark your curiosity and deepen your understanding of this chemistry marvel. From its ancient origins to its modern applications, saponification has a rich history and continues to play a significant role in various industries. So, let’s dig into the world of saponification and uncover the astonishing secrets behind soap-making!

Key Takeaways:

- Saponification is the cool chemical process that makes soap by mixing fats or oils with an alkali. It’s like a science experiment that creates something we use every day!

- Soap making is like a fun science project that combines precise measurements and creativity to produce different types of soap with unique properties and scents. It’s a mix of art and science!

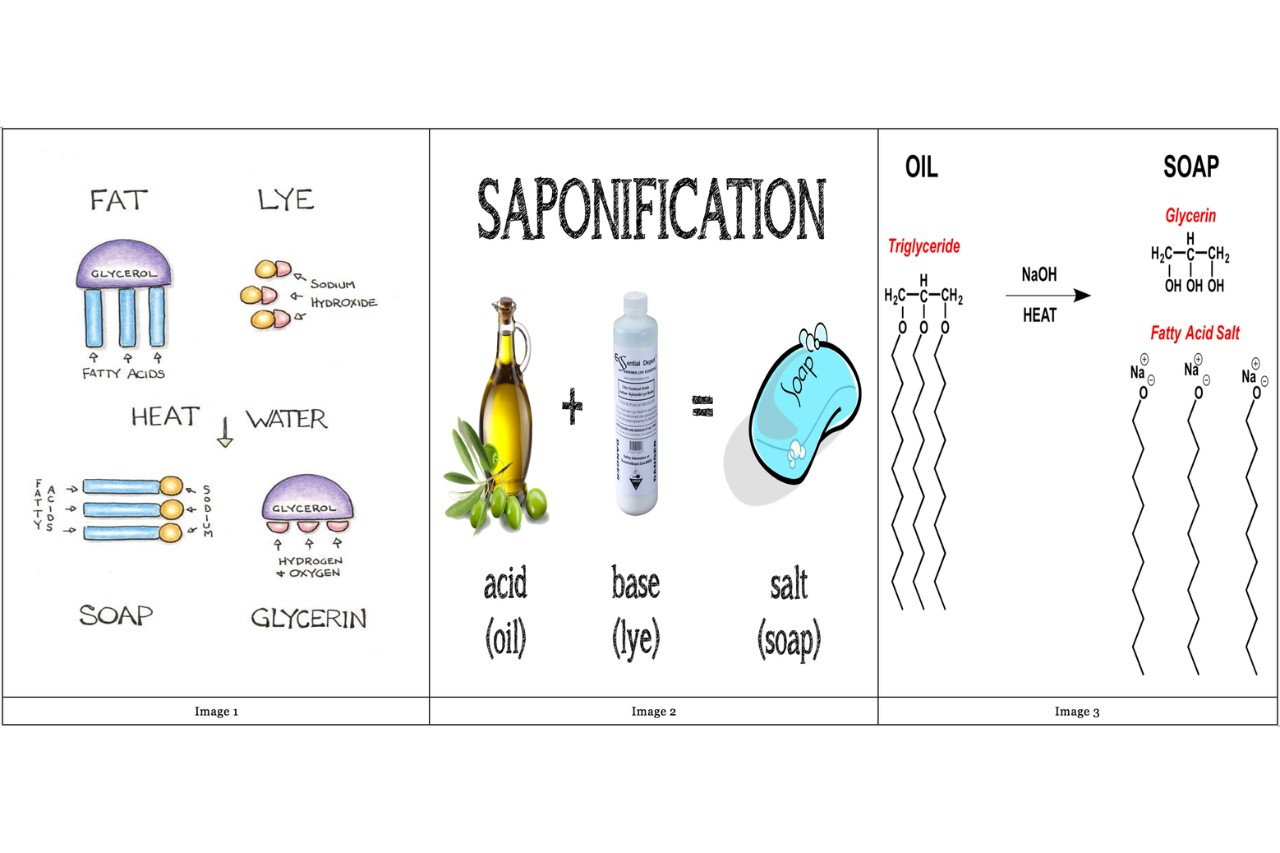

Saponification is the process of making soap.

It involves the chemical reaction between fats or oils and an alkali, typically sodium hydroxide or potassium hydroxide. This reaction results in the formation of soap and glycerol.

Soap has been used for thousands of years.

Historically, soap has been traced back to ancient civilizations such as Mesopotamia, Egypt, and Rome. These early soaps were made using a mixture of animal fats and ashes.

Saponification is an exothermic reaction.

During saponification, heat is released as a byproduct of the chemical reaction. This is why soap-making often requires the use of external heat sources to facilitate the process.

Soap can be made using different techniques.

There are various methods of making soap, including cold process, hot process, and melt and pour. Each technique has its own advantages and produces soap with different characteristics.

Glycerin is a byproduct of saponification.

When fats or oils undergo saponification, glycerin is formed as a result. Glycerin is a moisturizing ingredient commonly used in skincare products.

Soap acts as a surfactant.

A surfactant is a substance that reduces the surface tension between two liquids or between a liquid and a solid. This allows soap to effectively clean and remove dirt and oils.

Soap can be scented and colored.

Essential oils, fragrance oils, and natural botanicals can be added to soap during the saponification process to create unique scents. Likewise, various colorants can be used to give soap its vibrant hues.

Saponification can be used to produce solid or liquid soap.

Depending on the specific formulation and technique used, saponification can yield bar soaps or liquid soaps. Liquid soaps often require the addition of additional ingredients to maintain the desired consistency.

Soap has a pH level above 7.

Due to the alkaline nature of the saponification process, soap typically has a pH level above This makes it slightly basic in nature.

Saponification can be a complex chemical reaction.

The process of saponification involves multiple chemical reactions and the formation of various intermediates. The exact mechanisms can vary depending on the types of fats or oils used.

Soap making is both an art and a science.

Creating soap requires precise measurements, careful temperature control, and an understanding of the chemical processes involved. However, it also allows for creativity and personalization through the use of different ingredients and techniques.

Soap can have different properties depending on the ingredients used.

The choice of fats or oils, additives, and essential oils can all affect the final properties of the soap. This includes factors such as hardness, lather, moisturizing properties, and scent.

Saponification is used in other industries besides soap making.

Besides soap production, saponification is also used in the production of biodiesel, emulsifiers, and certain pharmaceuticals. It is a versatile chemical reaction with various applications.

Conclusion

In conclusion, saponification is a fascinating chemical process with numerous interesting facts. From its historical significance to its applications in our daily lives, saponification plays a crucial role in the world of chemistry and beyond.We have explored 13 extraordinary facts about saponification, including the origins of soap making, the role of fatty acids and alkalis, and the science behind cleansing and emulsification properties of soap. We have also delved into the different types of soap and the environmental impact of soap production.Understanding saponification not only enhances our appreciation for the products we use every day but also highlights the complex reactions taking place at the molecular level. So, the next time you lather up, remember the science behind saponification and the incredible chemistry that makes it all possible.

FAQs

Q: What is saponification?

A: Saponification is a chemical reaction that converts fats or oils into soap and glycerol. It involves the reaction of a triglyceride with an alkali, usually sodium hydroxide or potassium hydroxide.

Q: What is the history behind saponification?

A: The process of saponification has been known for thousands of years, with the earliest evidence of soap production dating back to ancient Mesopotamia around 2800 BCE. Soap was initially made by boiling animal fats with wood ashes.

Q: How does saponification work?

A: During saponification, the ester bonds in triglycerides are broken, and the fatty acids react with the alkali, resulting in the formation of soap molecules and glycerol as a byproduct.

Q: What are some common applications of saponification?

A: Saponification is widely used in the production of soaps, cosmetics, and detergents. It is also utilized in the food industry, pharmaceuticals, and even in the production of biodiesel.

Q: Are there different types of soap?

A: Yes, there are different types of soap produced through saponification, including bar soaps, liquid soaps, and specialty soaps such as medicated soaps and transparent soaps.

Q: What is the environmental impact of saponification?

A: While natural soap production through saponification is generally considered environmentally friendly, the disposal of soap waste or the excessive use of synthetic ingredients in commercial soaps can have negative ecological impacts.

Q: Can saponification occur naturally?

A: Yes, saponification can occur naturally. When fats or oils come into contact with naturally occurring alkalis in water, saponification can occur, leading to the formation of soap-like substances.

Q: Is saponification reversible?

A: No, saponification is an irreversible chemical reaction. Once the triglycerides have been converted into soap and glycerol, they cannot be easily converted back into their original form.

Q: How does saponification affect the pH of soap?

A: Saponification results in the formation of soap, which is typically alkaline in nature. This means that soap has a higher pH, usually around 9-10, making it mildly basic.

Q: Can saponification occur with any type of fat or oil?

A: Saponification can occur with most types of fats or oils, but some oils may produce soap with different properties. For example, coconut oil tends to produce a harder soap, while olive oil creates a softer soap.

Q: Is saponification only used to produce soap?

A: No, while soap production is one of the primary uses of saponification, it is also utilized in other industries, such as in the production of cosmetics, detergents, and various personal care products.

Q: Are there any safety considerations when working with saponification?

A: Yes, when working with saponification, it is important to handle alkalis, such as sodium hydroxide or potassium hydroxide, with care as they can cause burns and skin irritation. Protective equipment should be worn during the process.

Q: Can saponification be performed at home?

A: Yes, saponification can be done at home by following specific recipes and safety precautions. However, working with alkalis requires careful handling, so it is essential to understand the process thoroughly before attempting it.

Was this page helpful?

Our commitment to delivering trustworthy and engaging content is at the heart of what we do. Each fact on our site is contributed by real users like you, bringing a wealth of diverse insights and information. To ensure the highest standards of accuracy and reliability, our dedicated editors meticulously review each submission. This process guarantees that the facts we share are not only fascinating but also credible. Trust in our commitment to quality and authenticity as you explore and learn with us.