Alumel is a nickel-based alloy known for its excellent thermoelectric properties. Used primarily in thermocouples, it plays a crucial role in temperature measurement. But what makes Alumel so special? It's the unique blend of nickel, manganese, aluminum, and silicon that gives it remarkable stability and durability. This alloy can withstand high temperatures and harsh environments, making it indispensable in industries like aerospace, automotive, and manufacturing. Did you know that Alumel is often paired with Chromel to create Type K thermocouples? These thermocouples are among the most widely used due to their wide temperature range and reliability. Whether you're a science enthusiast or just curious about materials, learning about Alumel offers a fascinating glimpse into the world of advanced alloys.

Key Takeaways:

- Alumel, a nickel-based alloy, is widely used in temperature measurement due to its exceptional properties, such as resistance to corrosion and high thermoelectric power. It has diverse applications in industries, space missions, art, education, and DIY projects.

- While Alumel offers great benefits, it also comes with challenges such as cost, availability, and the need for regular calibration. Its magnetic properties and susceptibility to wear and tear require careful consideration and maintenance in various applications.

What is Alumel?

Alumel is a nickel-based alloy known for its exceptional thermoelectric properties. It is often used in thermocouples, which are devices that measure temperature. Let's dive into some fascinating facts about this unique material.

-

Composition: Alumel is primarily composed of nickel (95%), with small amounts of aluminum (2%), manganese (2%), and silicon (1%).

-

Thermocouples: Alumel is commonly paired with Chromel to form a type K thermocouple, which is widely used in industrial temperature measurement.

-

Temperature Range: Type K thermocouples, made from Alumel and Chromel, can measure temperatures ranging from -200°C to 1260°C.

-

Magnetic Properties: Alumel is magnetic, which can be useful in certain applications where magnetic properties are needed.

-

Corrosion Resistance: This alloy is resistant to oxidation and corrosion, making it suitable for harsh environments.

Uses of Alumel

Alumel's unique properties make it valuable in various applications, particularly in temperature measurement and control.

-

Industrial Furnaces: Alumel is used in thermocouples for monitoring and controlling the temperature in industrial furnaces.

-

Aerospace: In the aerospace industry, Alumel thermocouples are used to measure the temperature of jet engines and other critical components.

-

Automotive: Alumel is used in exhaust gas temperature sensors to monitor and control emissions in vehicles.

-

Scientific Research: Researchers use Alumel thermocouples in experiments that require precise temperature measurements.

-

Power Plants: Alumel is used in power plants to monitor the temperature of boilers and other equipment.

Properties of Alumel

Understanding the properties of Alumel helps in appreciating its wide range of applications.

-

Electrical Conductivity: Alumel has good electrical conductivity, which is essential for its use in thermocouples.

-

Thermoelectric Power: The alloy has a high thermoelectric power, making it effective in converting temperature differences into electrical voltage.

-

Mechanical Strength: Alumel is known for its mechanical strength, which allows it to withstand high temperatures and harsh conditions.

-

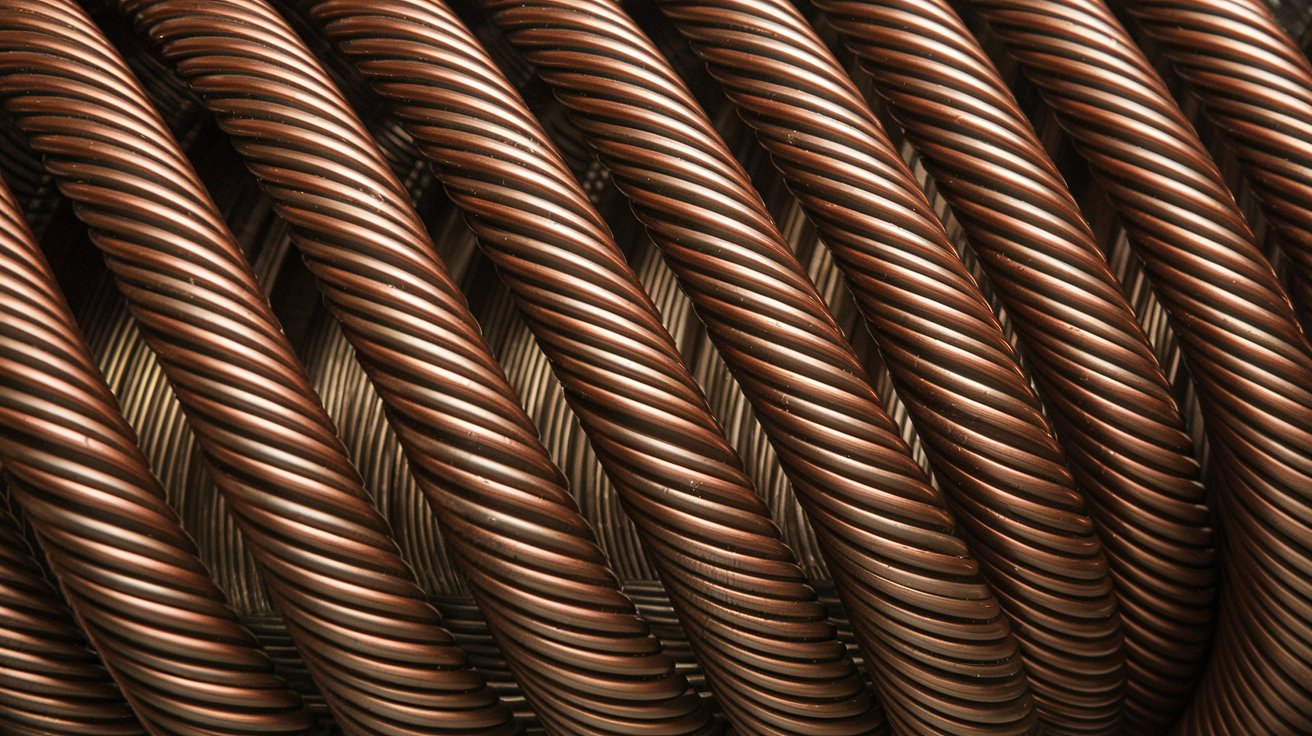

Ductility: This material is ductile, meaning it can be drawn into wires without breaking.

-

Thermal Stability: Alumel maintains its properties over a wide temperature range, ensuring reliable performance.

Historical Background

The history of Alumel is as intriguing as its properties and uses.

-

Invention: Alumel was developed in the early 20th century as part of the search for better materials for thermocouples.

-

Patents: The alloy was patented in the 1930s, marking a significant advancement in temperature measurement technology.

-

Industrial Adoption: By the mid-20th century, Alumel had become the standard material for thermocouples in many industries.

-

Continuous Improvement: Over the years, the composition and manufacturing processes of Alumel have been refined to enhance its performance.

-

Global Use: Today, Alumel is used worldwide in various industries, from manufacturing to scientific research.

Fun Facts about Alumel

Let's explore some lesser-known, fun facts about Alumel that highlight its versatility and importance.

-

Space Missions: Alumel thermocouples have been used in space missions to monitor the temperature of spacecraft components.

-

Art Installations: Some artists use Alumel in their installations due to its unique properties and appearance.

-

Educational Tools: Alumel thermocouples are often used in educational settings to teach students about temperature measurement and materials science.

-

DIY Projects: Hobbyists and DIY enthusiasts sometimes use Alumel in their projects, particularly those involving temperature control.

-

Recycling: Alumel can be recycled, making it an environmentally friendly choice for various applications.

Challenges and Limitations

Despite its many advantages, Alumel has some challenges and limitations.

-

Cost: Alumel can be expensive compared to other materials, which may limit its use in cost-sensitive applications.

-

Availability: The availability of high-quality Alumel can be an issue in some regions, affecting its widespread adoption.

-

Calibration: Thermocouples made from Alumel require regular calibration to ensure accurate temperature measurements.

-

Interference: Magnetic properties can cause interference in certain applications, requiring careful consideration during design and implementation.

-

Wear and Tear: Over time, Alumel can degrade due to exposure to extreme temperatures and harsh environments, necessitating regular maintenance and replacement.

Final Thoughts on Alumel

Alumel, a key player in thermocouples, stands out for its unique properties. This nickel-based alloy, known for its high thermal conductivity and resistance to oxidation, makes it indispensable in temperature measurement. Its ability to maintain stability at high temperatures ensures accurate readings, crucial in industries like aerospace and manufacturing.

Understanding the significance of Alumel helps appreciate its role in safety and efficiency. Its compatibility with Chromel in K-type thermocouples highlights its importance in precise temperature monitoring. This combination provides reliable data, essential for maintaining optimal conditions in various applications.

Incorporating Alumel into thermocouples showcases the blend of science and practicality. Its durability and performance under extreme conditions make it a trusted choice. Recognizing these facts about Alumel not only broadens knowledge but also underscores its value in technological advancements.

Frequently Asked Questions

Was this page helpful?

Our commitment to delivering trustworthy and engaging content is at the heart of what we do. Each fact on our site is contributed by real users like you, bringing a wealth of diverse insights and information. To ensure the highest standards of accuracy and reliability, our dedicated editors meticulously review each submission. This process guarantees that the facts we share are not only fascinating but also credible. Trust in our commitment to quality and authenticity as you explore and learn with us.