Friction stir welding (FSW) might sound like something out of a sci-fi movie, but it's a real and revolutionary way to join materials. Invented in 1991, this technique uses a non-consumable tool to join two facing workpieces without melting them. Instead, the tool generates frictional heat, softening the material and allowing it to mix and bond. This method is known for producing strong, high-quality welds with minimal defects. FSW is used in various industries, including aerospace, automotive, and shipbuilding. Curious about how this process works and its benefits? Here are 35 fascinating facts about friction stir welding that will spark your interest and expand your knowledge.

What is Friction Stir Welding?

Friction Stir Welding (FSW) is a solid-state joining process that uses frictional heat to join materials. This technique is widely used in various industries due to its efficiency and strength. Let's dive into some fascinating facts about this innovative welding method.

- Invented in 1991 by The Welding Institute (TWI) in the UK, FSW has revolutionized the welding industry.

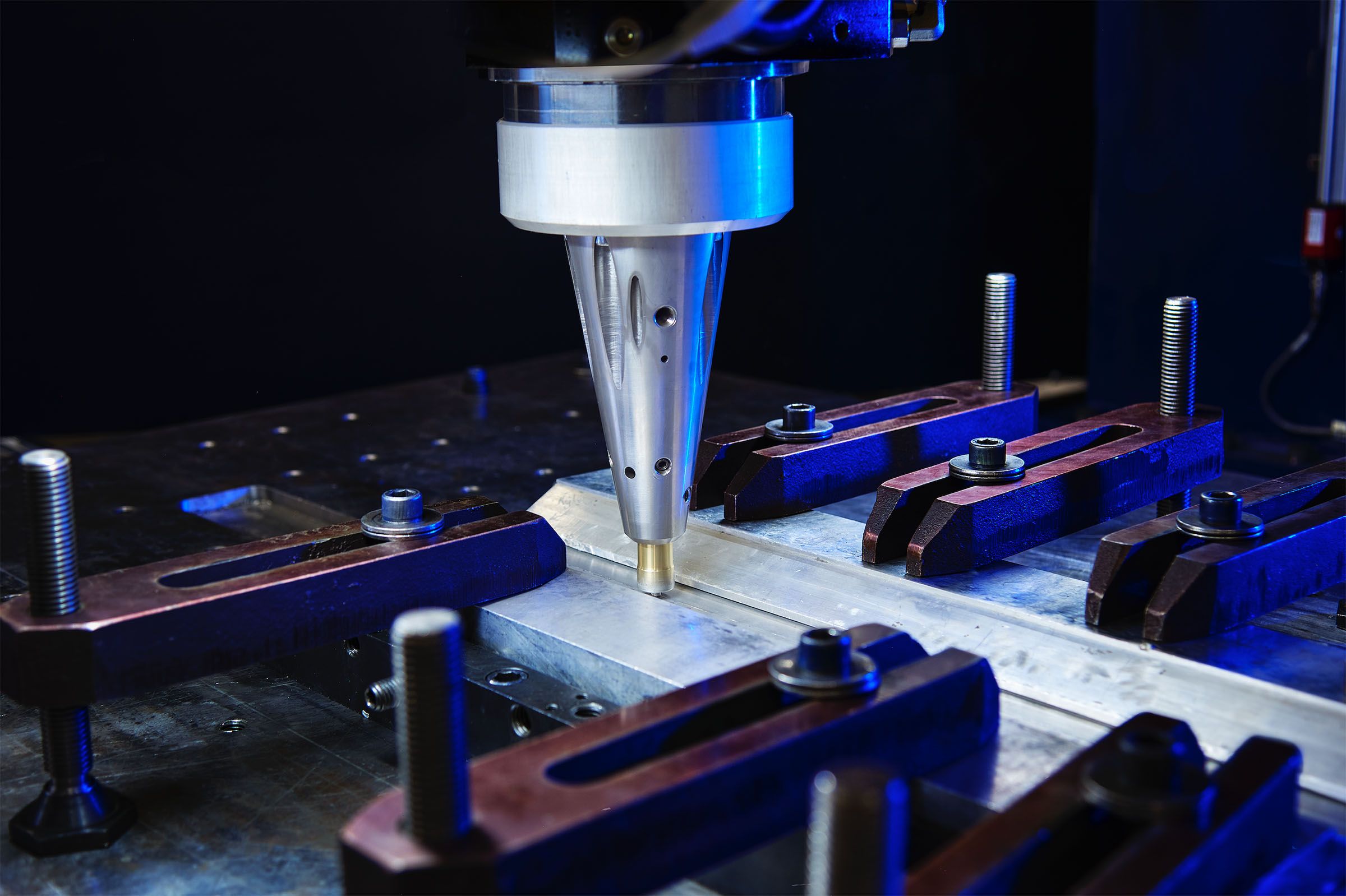

- Unlike traditional welding, FSW does not melt the materials being joined. Instead, it uses frictional heat to soften and mix the materials.

- FSW is primarily used for joining aluminum, but it can also be used for other metals like copper, titanium, and steel.

- The process involves a rotating tool that generates heat through friction, creating a plasticized zone that allows the materials to be joined.

- FSW produces welds with high strength and low distortion, making it ideal for applications requiring precision and durability.

Applications of Friction Stir Welding

FSW is utilized in various industries due to its unique advantages. Here are some key applications where FSW shines.

- The aerospace industry uses FSW for constructing lightweight and strong components for aircraft and spacecraft.

- In the automotive sector, FSW is employed to join aluminum parts, reducing vehicle weight and improving fuel efficiency.

- Shipbuilding benefits from FSW by creating strong, watertight joints in aluminum hulls and decks.

- The railway industry uses FSW to manufacture lightweight and durable train carriages.

- FSW is also used in the construction of bridges and other infrastructure projects, providing strong and reliable joints.

Advantages of Friction Stir Welding

FSW offers numerous benefits over traditional welding methods. Let's explore some of these advantages.

- FSW produces welds with minimal defects, such as porosity and cracking, resulting in higher quality joints.

- The process is energy-efficient, as it requires less heat input compared to conventional welding methods.

- FSW can join dissimilar materials, expanding its versatility in various applications.

- The absence of filler materials and shielding gases reduces the overall cost of the welding process.

- FSW generates low levels of fumes and spatter, making it an environmentally friendly option.

Challenges and Limitations of Friction Stir Welding

Despite its many advantages, FSW also has some challenges and limitations. Here are a few to consider.

- The initial cost of FSW equipment can be high, making it less accessible for small-scale operations.

- FSW is primarily limited to linear and simple curved joints, restricting its use in complex geometries.

- The process requires precise control of parameters, such as tool rotation speed and travel speed, to achieve optimal results.

- FSW can generate significant forces, necessitating robust fixturing and clamping systems.

- The process may not be suitable for very thick materials, as it can be challenging to achieve full penetration.

Innovations and Future Developments in Friction Stir Welding

FSW continues to evolve, with ongoing research and development leading to new innovations. Here are some exciting advancements in the field.

- Researchers are developing new tool materials and designs to improve the efficiency and durability of FSW tools.

- Advances in automation and robotics are making FSW more accessible and cost-effective for various industries.

- Hybrid welding techniques, combining FSW with other welding methods, are being explored to enhance joint properties and expand application possibilities.

- The use of FSW in additive manufacturing is being investigated, potentially revolutionizing the production of complex metal parts.

- Ongoing research aims to extend the capabilities of FSW to thicker materials and more complex geometries.

Environmental Impact of Friction Stir Welding

FSW is considered an environmentally friendly welding method. Let's look at some reasons why.

- FSW generates minimal fumes and spatter, reducing air pollution and improving workplace safety.

- The process requires less energy compared to traditional welding methods, lowering overall energy consumption.

- The absence of filler materials and shielding gases reduces waste and resource usage.

- FSW can join recycled materials, promoting sustainability and reducing the demand for new raw materials.

- The high-quality welds produced by FSW can extend the lifespan of products, reducing the need for replacements and conserving resources.

Real-World Examples of Friction Stir Welding

FSW has been successfully implemented in various real-world applications. Here are some notable examples.

- NASA uses FSW to construct fuel tanks and other components for spacecraft, ensuring high strength and reliability.

- Boeing employs FSW in the manufacturing of its 787 Dreamliner, joining aluminum and titanium parts for improved performance.

- The London Eye, a famous Ferris wheel, features FSW joints in its aluminum capsules, providing strength and durability.

- The automotive company Audi uses FSW to join aluminum body panels in its vehicles, enhancing safety and reducing weight.

- The European Space Agency (ESA) utilizes FSW in the construction of satellite components, ensuring robust and reliable joints.

Final Thoughts on Friction Stir Welding

Friction stir welding (FSW) is a game-changer in the world of manufacturing. This innovative technique joins materials without melting them, resulting in stronger, more reliable bonds. It's used in various industries, from aerospace to automotive, thanks to its ability to create high-quality welds with minimal defects.

FSW is also environmentally friendly. It produces less waste and consumes less energy compared to traditional welding methods. This makes it a sustainable choice for companies looking to reduce their carbon footprint.

Moreover, FSW can join dissimilar materials, opening up new possibilities for design and engineering. Its versatility and efficiency make it a valuable tool for modern manufacturing.

Understanding the basics of FSW can help you appreciate the advancements in welding technology. Whether you're a student, a professional, or just curious, knowing about FSW can broaden your knowledge and spark interest in the field of materials science.

Was this page helpful?

Our commitment to delivering trustworthy and engaging content is at the heart of what we do. Each fact on our site is contributed by real users like you, bringing a wealth of diverse insights and information. To ensure the highest standards of accuracy and reliability, our dedicated editors meticulously review each submission. This process guarantees that the facts we share are not only fascinating but also credible. Trust in our commitment to quality and authenticity as you explore and learn with us.