Stereolithography (SLA) is a game-changer in the world of 3D printing. But what exactly makes it so special? SLA uses a laser to cure liquid resin into hardened plastic, layer by layer. This method allows for incredibly detailed and precise prints, making it a favorite for prototypes, dental models, and intricate designs. Unlike other 3D printing techniques, SLA can produce smooth surfaces without the need for extensive post-processing. It's also known for its speed and efficiency, often completing projects faster than other methods. Curious about more? Let's dive into 33 fascinating facts about SLA that will blow your mind!

What is Stereolithography (SLA)?

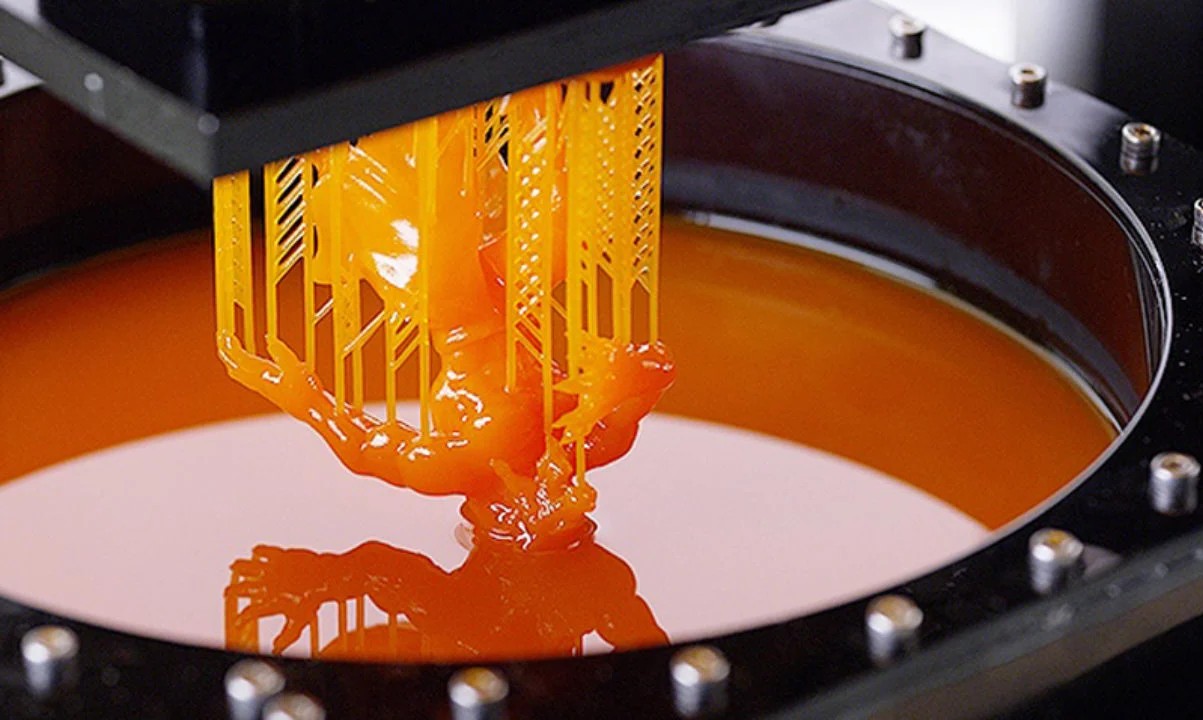

Stereolithography (SLA) is a type of 3D printing technology that uses a laser to cure liquid resin into hardened plastic. This process is known for its precision and ability to create detailed and complex parts.

-

SLA was invented in 1986 by Charles Hull, who also co-founded 3D Systems, a company that remains a leader in the 3D printing industry.

-

The term "stereolithography" comes from the Greek words "stereos" (solid) and "lithos" (stone), combined with "graphy" (writing), essentially meaning "solid writing."

-

SLA uses a UV laser to trace a pattern on the surface of a liquid photopolymer resin, which then hardens layer by layer to form a solid object.

-

SLA can achieve layer thicknesses as small as 25 microns, allowing for incredibly detailed and smooth surfaces.

How Does SLA Work?

Understanding the process behind SLA can help appreciate its capabilities and applications.

-

The process begins with a CAD model that is sliced into thin layers using specialized software.

-

A build platform is submerged in a vat of liquid resin, with the UV laser tracing the first layer of the object on the surface.

-

Once the first layer is cured, the build platform lowers slightly, and the next layer is traced and cured. This process repeats until the entire object is formed.

-

After printing, the object is usually rinsed in a solvent to remove any uncured resin and then cured further in a UV oven to ensure complete hardening.

Applications of SLA

SLA technology is versatile and used in various industries for different applications.

-

SLA is popular in the dental industry for creating custom dental implants, crowns, and bridges due to its precision.

-

In the medical field, SLA is used to produce surgical guides, prosthetics, and even anatomical models for educational purposes.

-

The jewelry industry benefits from SLA's ability to create intricate designs, which are then cast in metal.

-

SLA is also used in prototyping, allowing designers to create detailed models quickly and accurately.

Advantages of SLA

SLA offers several benefits that make it a preferred choice for many applications.

-

High resolution and accuracy are among the top advantages, making it ideal for detailed and complex parts.

-

Smooth surface finish reduces the need for post-processing, saving time and effort.

-

Material versatility allows for the use of different resins, each with unique properties suited for specific applications.

-

Speed of production is another advantage, as SLA can produce parts faster than many traditional manufacturing methods.

Limitations of SLA

Despite its many benefits, SLA has some limitations that users should be aware of.

-

Material cost can be high, as the specialized resins used in SLA are more expensive than other 3D printing materials.

-

Post-processing requirements such as rinsing and additional curing can add time and complexity to the process.

-

Limited material strength compared to other 3D printing methods, making SLA parts less suitable for functional or load-bearing applications.

-

Size limitations exist, as the build volume of SLA printers is generally smaller than other types of 3D printers.

Innovations in SLA

Recent advancements have improved the capabilities and applications of SLA technology.

-

New resin formulations have been developed, offering improved mechanical properties and biocompatibility.

-

Hybrid SLA printers combine SLA with other technologies, such as Digital Light Processing (DLP), to enhance speed and resolution.

-

Automated post-processing systems are being introduced, reducing the manual effort required after printing.

-

Software advancements have improved the slicing process, making it easier to prepare models for printing.

Environmental Impact of SLA

Considering the environmental impact of SLA is important for sustainable practices.

-

Resin waste can be an issue, as unused resin must be disposed of properly to avoid environmental harm.

-

Energy consumption of SLA printers is relatively high due to the use of UV lasers and curing ovens.

-

Recycling options for SLA materials are limited, though some companies are working on developing recyclable resins.

-

Eco-friendly resins are being developed, which are biodegradable and less harmful to the environment.

Future of SLA

The future of SLA looks promising with ongoing research and development.

-

Continuous improvements in resin formulations will likely lead to stronger, more durable materials.

-

Increased automation in the printing and post-processing stages will make SLA more accessible and user-friendly.

-

Cost reductions are expected as the technology matures and becomes more widely adopted.

-

Integration with other technologies, such as AI and machine learning, could further enhance the capabilities of SLA printers.

-

Expansion into new industries will continue as the benefits of SLA become more widely recognized and utilized.

The Final Layer

Stereolithography (SLA) has revolutionized the world of 3D printing. From its precise laser technology to its ability to create intricate designs, SLA stands out in the additive manufacturing industry. Its applications span from medical models to jewelry and engineering prototypes. The process, though complex, offers unmatched detail and smooth finishes.

Understanding the ins and outs of SLA can help you appreciate its impact on various fields. Whether you're a hobbyist or a professional, knowing these 33 facts can give you a deeper insight into why SLA is a game-changer. As technology advances, SLA will likely continue to evolve, offering even more possibilities.

So, next time you see a finely detailed 3D printed object, you'll know the magic behind it. Stereolithography isn't just a method; it's a leap into the future of manufacturing.

Was this page helpful?

Our commitment to delivering trustworthy and engaging content is at the heart of what we do. Each fact on our site is contributed by real users like you, bringing a wealth of diverse insights and information. To ensure the highest standards of accuracy and reliability, our dedicated editors meticulously review each submission. This process guarantees that the facts we share are not only fascinating but also credible. Trust in our commitment to quality and authenticity as you explore and learn with us.