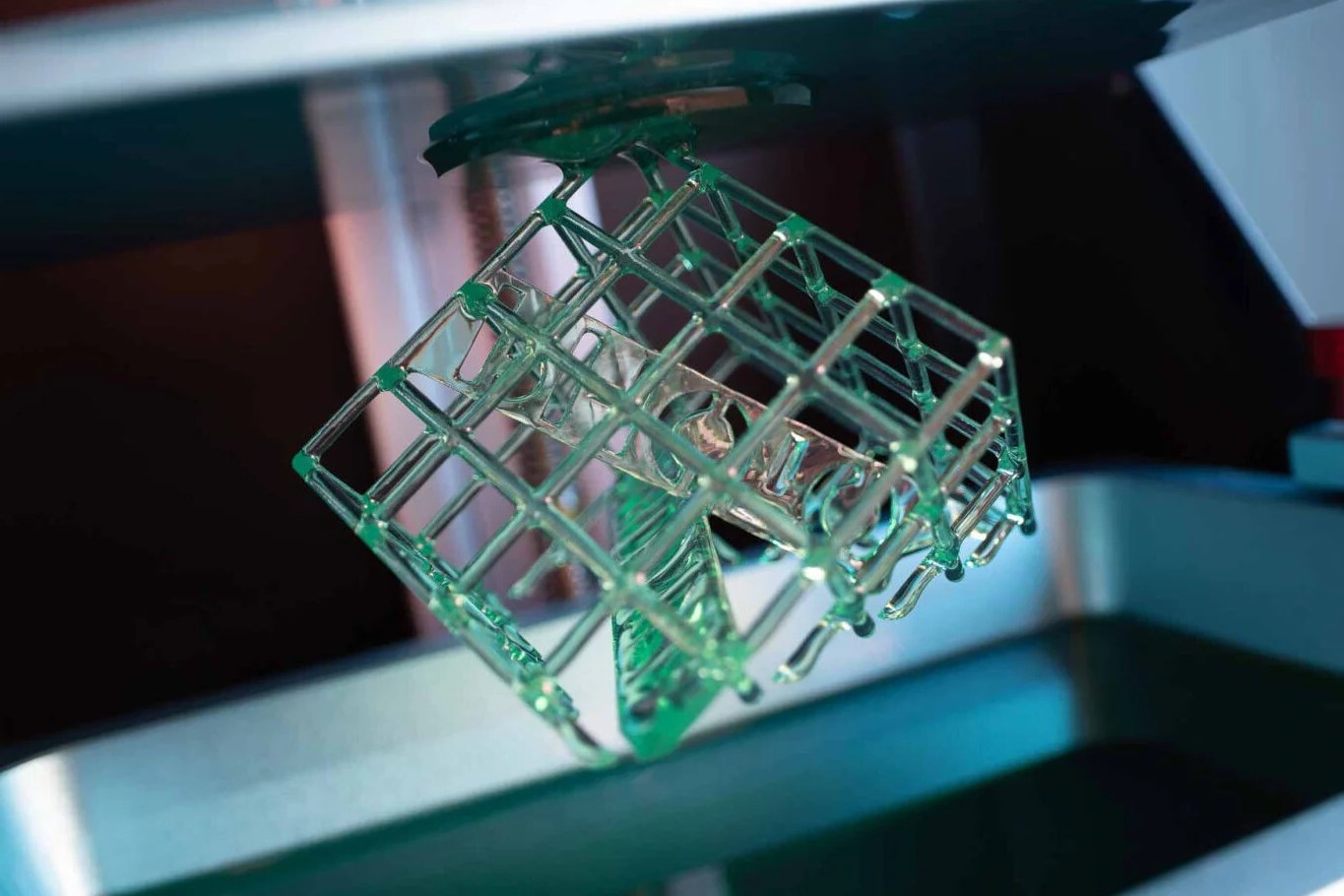

Digital Light Processing (DLP) printers have revolutionized the world of 3D printing, offering precision and speed that other technologies struggle to match. But what exactly makes these printers so special? DLP printers use a digital light projector to flash a single image of each layer across the entire platform, curing the resin in one go. This method allows for incredibly detailed prints and faster production times. DLP technology is not just for hobbyists; industries like dentistry, jewelry, and engineering rely on it for creating intricate designs and prototypes. Curious about how this tech works or its benefits? Read on to uncover 39 fascinating facts about DLP printers that will enlighten your understanding and maybe even inspire your next project.

What is a Digital Light Processing (DLP) Printer?

Digital Light Processing (DLP) printers are a type of 3D printer that use light to cure photopolymer resin. This technology is known for its precision and speed, making it popular in various industries.

-

DLP printers use a digital micromirror device (DMD) to project light onto a resin surface. The DMD consists of thousands of tiny mirrors that direct light to create an image.

-

The light source in DLP printers is usually a UV lamp or LED. This light cures the resin layer by layer, solidifying it into the desired shape.

-

DLP printers can achieve high resolution. The resolution depends on the number of micromirrors in the DMD and the size of each mirror.

How Do DLP Printers Work?

Understanding the working mechanism of DLP printers can help appreciate their efficiency and precision.

-

A digital image is created using CAD software. This image is sliced into thin layers, which the printer will build one at a time.

-

The DMD projects each layer onto the resin. The light hardens the resin in the shape of the layer, and the build platform moves to allow the next layer to be projected.

-

The process repeats until the entire object is formed. Each layer is cured quickly, allowing for faster printing times compared to other 3D printing technologies.

Advantages of DLP Printers

DLP printers offer several benefits that make them a preferred choice for many applications.

-

High precision and detail are achievable due to the fine resolution of the DMD.

-

Faster print times compared to other 3D printing methods like FDM (Fused Deposition Modeling).

-

Smooth surface finish on printed objects, reducing the need for post-processing.

-

Ability to print complex geometries that would be difficult or impossible with other methods.

Applications of DLP Printers

DLP printers are used in various fields due to their versatility and precision.

-

Dental industry uses DLP printers for creating accurate dental models, crowns, and bridges.

-

Jewelry making benefits from the high detail and precision, allowing for intricate designs.

-

Prototyping in engineering and product design, enabling rapid iteration and testing.

-

Medical field for creating custom prosthetics and anatomical models.

Materials Used in DLP Printing

The choice of materials can affect the properties and applications of the printed objects.

-

Photopolymer resins are the primary material used in DLP printing. These resins harden when exposed to light.

-

Specialized resins are available for different applications, such as dental resins, castable resins for jewelry, and biocompatible resins for medical use.

-

Flexible resins can be used to create objects that need to bend or flex.

Maintenance and Care for DLP Printers

Proper maintenance ensures the longevity and performance of DLP printers.

-

Regular cleaning of the build platform and resin vat to prevent contamination and ensure smooth printing.

-

Replacing the resin vat periodically to avoid issues with adhesion and print quality.

-

Checking and replacing the light source as needed to maintain optimal curing performance.

-

Calibrating the printer regularly to ensure accuracy and precision.

Challenges and Limitations of DLP Printers

Despite their advantages, DLP printers have some challenges and limitations.

-

Limited build volume compared to other 3D printing technologies, restricting the size of objects that can be printed.

-

Resin handling and disposal require care, as uncured resin can be toxic and harmful to the environment.

-

Initial cost of DLP printers can be higher than other types of 3D printers.

-

Post-processing is often required to remove supports and clean the printed object.

Innovations in DLP Printing

Continuous advancements are being made to improve DLP printing technology.

-

Development of new resins with enhanced properties, such as higher strength and flexibility.

-

Improved light sources for faster curing times and better print quality.

-

Integration with other technologies like AI for optimizing print settings and improving accuracy.

-

Enhanced software for better slicing and more efficient printing processes.

Environmental Impact of DLP Printing

Considering the environmental impact is crucial for sustainable use of DLP printers.

-

Recycling of resin waste can help reduce the environmental footprint.

-

Development of eco-friendly resins made from renewable resources.

-

Energy-efficient light sources can reduce the overall energy consumption of the printing process.

Future of DLP Printing

The future of DLP printing looks promising with ongoing research and development.

-

Increased adoption in various industries as the technology becomes more accessible and affordable.

-

Advancements in materials will expand the range of applications for DLP printers.

-

Improved printer designs for larger build volumes and faster print times.

-

Integration with other manufacturing processes for hybrid production methods.

Fun Facts About DLP Printing

Some interesting tidbits about DLP printing that you might not know.

-

DLP technology was originally developed for projectors before being adapted for 3D printing.

-

The first DLP printer was introduced in the early 2000s. It has since evolved significantly.

-

DLP printers can create objects with intricate internal structures that are impossible to produce with traditional manufacturing methods.

Final Thoughts on DLP Printers

DLP printers have revolutionized the world of 3D printing. They offer high precision, speed, and versatility, making them a top choice for hobbyists and professionals alike. With their ability to produce detailed and complex designs, DLP printers are perfect for creating prototypes, jewelry, dental models, and more.

Understanding the key features and benefits of DLP technology helps you make informed decisions about your 3D printing needs. From the importance of resolution and build volume to the types of resins used, every detail matters.

Whether you're new to 3D printing or looking to upgrade your current setup, DLP printers provide a reliable and efficient solution. Keep exploring, experimenting, and pushing the boundaries of what you can create. The future of 3D printing is bright, and DLP technology is leading the way.

Was this page helpful?

Our commitment to delivering trustworthy and engaging content is at the heart of what we do. Each fact on our site is contributed by real users like you, bringing a wealth of diverse insights and information. To ensure the highest standards of accuracy and reliability, our dedicated editors meticulously review each submission. This process guarantees that the facts we share are not only fascinating but also credible. Trust in our commitment to quality and authenticity as you explore and learn with us.