What is a muffle furnace? A muffle furnace is a type of oven used for high-temperature applications, often reaching up to 1,800 degrees Fahrenheit. It isolates the material being heated from combustion byproducts, ensuring a clean environment. These furnaces are essential in laboratories for tasks like ashing, sintering, and heat treatment. They consist of a heating chamber surrounded by insulation, which helps maintain consistent temperatures. Modern muffle furnaces come with digital controls for precise temperature management. Their versatility makes them invaluable in fields such as ceramics, metallurgy, and material science. Whether you're a student or a professional, understanding muffle furnaces can open doors to advanced scientific exploration.

What is a Muffle Furnace?

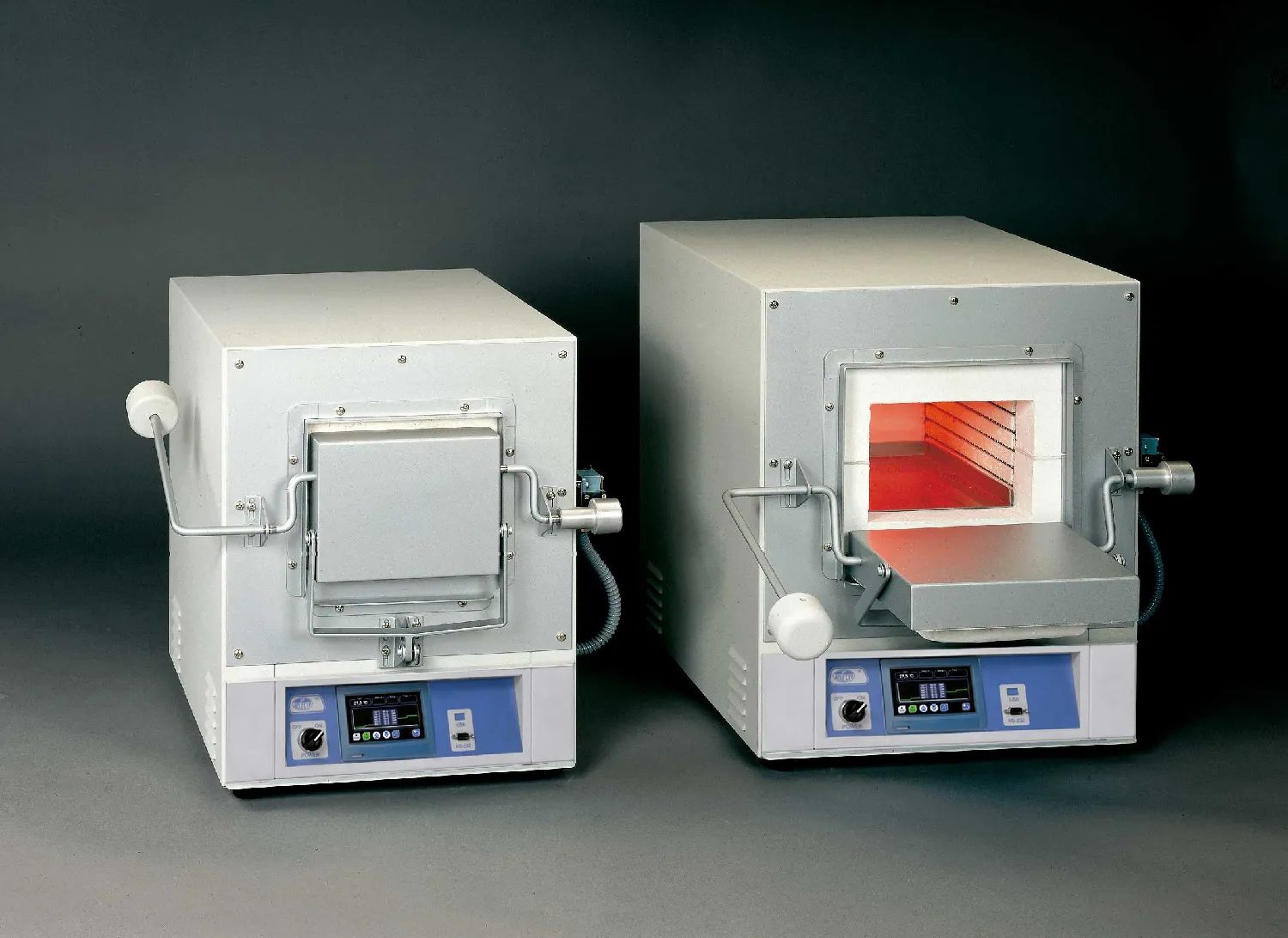

A muffle furnace is a type of oven used in laboratories and industrial settings for high-temperature applications. It isolates the material being heated from direct contact with the flame or heating element. This setup ensures uniform heating and prevents contamination.

-

High Temperatures: Muffle furnaces can reach temperatures up to 1800°C, making them ideal for tasks requiring extreme heat.

-

Uniform Heating: The design ensures even heat distribution, crucial for processes like annealing and sintering.

-

Contamination-Free: By isolating the sample from the heating element, muffle furnaces prevent contamination, essential for precise scientific experiments.

Applications of Muffle Furnaces

Muffle furnaces serve various purposes across different fields. Their versatility makes them indispensable in both research and industrial settings.

-

Material Testing: Used to test the properties of metals, ceramics, and other materials under high temperatures.

-

Ash Content Determination: Helps in determining the ash content in food, coal, and other substances.

-

Heat Treatment: Employed in processes like annealing, tempering, and stress relieving of metals.

-

Ceramic Firing: Essential for firing ceramics and pottery, ensuring uniform heating and quality results.

Components of a Muffle Furnace

Understanding the components of a muffle furnace helps in grasping its functionality and maintenance.

-

Heating Element: Usually made of materials like Kanthal or silicon carbide, responsible for generating heat.

-

Insulation: High-quality insulation materials like ceramic fiber prevent heat loss and ensure energy efficiency.

-

Temperature Controller: Advanced digital controllers allow precise temperature settings and monitoring.

-

Chamber: The inner chamber, often made of ceramic, withstands high temperatures and houses the sample.

Advantages of Using Muffle Furnaces

Muffle furnaces offer several benefits that make them a preferred choice for high-temperature applications.

-

Energy Efficiency: Modern muffle furnaces are designed to be energy-efficient, reducing operational costs.

-

Precision: Accurate temperature control ensures reliable and repeatable results.

-

Safety: Isolating the sample from the heating element minimizes the risk of contamination and accidents.

-

Versatility: Suitable for a wide range of applications, from material testing to heat treatment.

Maintenance and Care

Proper maintenance ensures the longevity and optimal performance of a muffle furnace.

-

Regular Cleaning: Keeping the chamber clean prevents contamination and extends the furnace's lifespan.

-

Inspection: Regularly inspect the heating elements and insulation for wear and tear.

-

Calibration: Periodic calibration of the temperature controller ensures accurate readings.

-

Replacement Parts: Use only manufacturer-recommended parts for replacements to maintain performance and safety.

Historical Background

The muffle furnace has a rich history, evolving over centuries to become the advanced equipment we use today.

-

Ancient Origins: Early versions date back to ancient civilizations, where they were used for metalworking and pottery.

-

Industrial Revolution: The design and functionality improved significantly during the Industrial Revolution, meeting the demands of new industries.

-

Modern Innovations: Today's muffle furnaces incorporate advanced materials and digital controls, enhancing efficiency and precision.

Common Issues and Troubleshooting

Even with proper maintenance, muffle furnaces can encounter issues. Knowing common problems and their solutions can save time and resources.

-

Temperature Fluctuations: Often caused by faulty heating elements or controllers. Regular inspection and calibration can prevent this.

-

Uneven Heating: May result from insulation damage or improper loading of the chamber. Ensure even distribution of samples and check insulation regularly.

-

Power Failures: Can disrupt processes and damage the furnace. Use surge protectors and ensure a stable power supply.

Future Trends in Muffle Furnace Technology

As technology advances, muffle furnaces continue to evolve, incorporating new features and capabilities.

-

Smart Controls: Integration with IoT for remote monitoring and control, enhancing convenience and efficiency.

-

Eco-Friendly Designs: Development of more energy-efficient models with reduced environmental impact.

The Final Word on Muffle Furnaces

Muffle furnaces are essential tools in many industries. They provide high temperatures for processes like annealing, sintering, and calcination. These furnaces are known for their ability to maintain a consistent temperature, which is crucial for precise results. They come in various sizes and configurations, making them versatile for different applications.

Safety is a top priority when using muffle furnaces. Always follow the manufacturer's guidelines and wear appropriate protective gear. Regular maintenance ensures the furnace operates efficiently and extends its lifespan.

Understanding the key features and benefits of muffle furnaces can help you choose the right one for your needs. Whether you're in research, manufacturing, or education, these furnaces play a vital role in achieving accurate and reliable results.

Stay informed and make the most of this powerful tool in your work.

Was this page helpful?

Our commitment to delivering trustworthy and engaging content is at the heart of what we do. Each fact on our site is contributed by real users like you, bringing a wealth of diverse insights and information. To ensure the highest standards of accuracy and reliability, our dedicated editors meticulously review each submission. This process guarantees that the facts we share are not only fascinating but also credible. Trust in our commitment to quality and authenticity as you explore and learn with us.