G-code, the essential language of CNC (Computer Numerical Control) machines, serves as the backbone of modern manufacturing and industrial automation. Understanding G-code is crucial for anyone involved in CNC machining, from operators to engineers. In this article, we'll delve into 12 key facts about G-code, shedding light on its significance, functionality, and impact on the manufacturing landscape.

From its origins to its role in driving precision manufacturing processes, G-code is a fascinating and pivotal aspect of modern technology. Whether you're a seasoned professional or simply curious about the inner workings of CNC machines, these facts will provide valuable insights into the world of G-code. So, let's embark on a journey to unravel the intricacies of G-code and gain a deeper appreciation for its role in shaping the future of manufacturing.

Key Takeaways:

- G-code is like the secret language that tells CNC machines how to make cool stuff with precision and efficiency. It’s like the conductor of an orchestra, making sure everything works together perfectly.

- Learning G-code is like becoming a wizard in the world of manufacturing. It’s a valuable skill that helps create amazing things and keeps pushing the boundaries of what’s possible in making stuff.

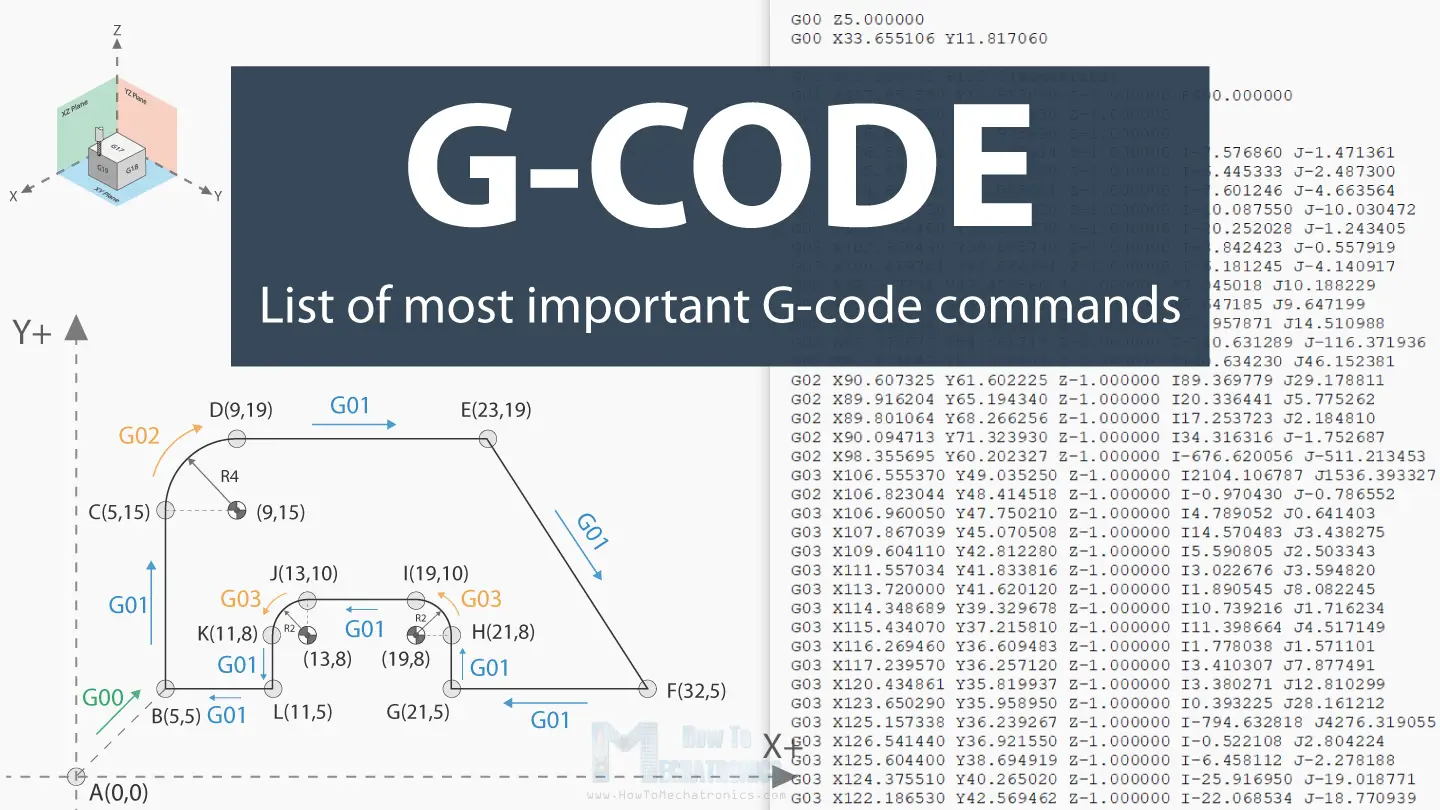

G-code is the language of CNC machines.

G-code, short for "geometric code," serves as the fundamental language for instructing computer numerical control (CNC) machines. This specialized code comprises a series of alphanumeric instructions that direct the movements and actions of CNC machinery, such as milling machines, lathes, and 3D printers. It essentially dictates the precise coordinates, speeds, and tooling operations necessary to produce a specific part or component.

G-code facilitates intricate machining operations.

With G-code, CNC machines can execute complex operations with remarkable precision. From intricate cuts and drilling to multi-axis movements, G-code enables the seamless orchestration of diverse machining tasks. This capability empowers manufacturers to craft intricate and customized components, ranging from aerospace parts to artistic sculptures, with unparalleled accuracy and efficiency.

G-code commands are standardized across CNC machines.

One of the remarkable aspects of G-code is its standardization across various CNC machines. This uniformity allows manufacturers and programmers to create G-code programs that can be executed on different CNC equipment, fostering interoperability and flexibility in manufacturing processes.

G-code is generated by CAM software.

Computer-aided manufacturing (CAM) software plays a pivotal role in generating G-code. By importing CAD (computer-aided design) models, CAM software translates the design specifications into G-code instructions, enabling seamless translation of digital designs into physical products.

G-code is editable for fine-tuning machining parameters.

Programmers and machinists can modify G-code to refine machining parameters and optimize the manufacturing process. This flexibility allows for adjustments in cutting speeds, tool paths, and other variables, empowering operators to enhance efficiency and precision based on specific project requirements.

G-code supports conditional logic and branching.

G-code's versatility extends to supporting conditional logic and branching, enabling the implementation of decision-making processes within machining operations. This capability allows CNC machines to adapt their actions based on real-time feedback, enhancing adaptability and responsiveness in manufacturing processes.

G-code is crucial for rapid prototyping and additive manufacturing.

In the realm of rapid prototyping and additive manufacturing, G-code plays a pivotal role in guiding the intricate layer-by-layer deposition of materials to realize three-dimensional objects. This application underscores the versatility of G-code in facilitating advanced manufacturing techniques.

G-code optimization enhances production efficiency.

Efficient G-code programming and optimization can significantly impact production efficiency by minimizing machining time, reducing material waste, and enhancing overall process reliability. This optimization process involves strategic planning and fine-tuning to maximize the performance of CNC machines.

G-code is integral to automated production systems.

As automation continues to revolutionize manufacturing, G-code remains integral to the seamless operation of automated production systems. Its role in orchestrating precise and repeatable machining actions aligns with the demands of modern automated manufacturing environments.

G-code proficiency is a valuable skill in the manufacturing industry.

Proficiency in G-code programming and interpretation is highly sought after in the manufacturing industry. Individuals with expertise in creating and interpreting G-code commands are instrumental in driving the efficiency and innovation of CNC-based manufacturing processes.

G-code advancements continue to evolve.

The landscape of G-code and CNC machining is marked by ongoing advancements and innovations. From the integration of artificial intelligence to the development of enhanced toolpath optimization algorithms, the evolution of G-code reflects the continuous pursuit of refining manufacturing capabilities.

G-code empowers creativity and precision in manufacturing.

Ultimately, G-code serves as a conduit for translating creative designs into meticulously crafted physical objects. Its role in empowering precision, flexibility, and innovation underscores its significance in driving the evolution of modern manufacturing processes.

By delving into the intricacies of G-code, we gain a deeper appreciation for its pivotal role in shaping the contemporary landscape of manufacturing and engineering. As we continue to harness the potential of CNC machines and additive manufacturing technologies, the foundational language of G-code remains an indispensable cornerstone of this transformative journey.

Conclusion

In conclusion, G-code is a fundamental aspect of CNC machining, serving as the language that instructs machines to create precise and intricate components. Understanding the intricacies of G-code empowers manufacturers and engineers to optimize production processes, minimize errors, and achieve exceptional precision. By delving into the 12 essential facts about G-code, individuals can gain a comprehensive grasp of its significance in the realm of CNC machining. From its role in dictating toolpaths to its utilization in diverse industries, G-code stands as a cornerstone of modern manufacturing, driving innovation and efficiency across various sectors.

FAQs

What are the primary functions of G-code in CNC machining?G-code serves as the primary language for instructing CNC machines, dictating tool movements, speeds, and other crucial parameters to execute precise manufacturing processes.

How does a comprehensive understanding of G-code benefit professionals in the manufacturing industry?Professionals equipped with a deep understanding of G-code can optimize production processes, minimize errors, and achieve exceptional precision, thereby enhancing efficiency and productivity in manufacturing operations.

Was this page helpful?

Our commitment to delivering trustworthy and engaging content is at the heart of what we do. Each fact on our site is contributed by real users like you, bringing a wealth of diverse insights and information. To ensure the highest standards of accuracy and reliability, our dedicated editors meticulously review each submission. This process guarantees that the facts we share are not only fascinating but also credible. Trust in our commitment to quality and authenticity as you explore and learn with us.