Ladder logic is a fundamental programming language used in programmable logic controllers (PLCs) to control industrial machinery and processes. It is a graphical representation of the control logic that resembles a ladder with two vertical rails and rungs between them. This intuitive and versatile language allows engineers and technicians to create complex control systems by arranging various logic elements in a ladder diagram.

Understanding the intricacies of ladder logic is crucial for anyone involved in industrial automation, as it forms the backbone of PLC programming. In this article, we will delve into 12 essential facts about ladder logic, shedding light on its significance, structure, and applications. Whether you are a seasoned automation professional or a newcomer to the field, these insights will deepen your understanding of this pivotal aspect of industrial control systems. So, let's embark on a journey to unravel the fascinating world of ladder logic and its role in shaping modern industrial automation.

Key Takeaways:

- Ladder Logic is like a special language for controlling machines in factories. It uses symbols to make programs that tell machines what to do, making it easier to understand and fix problems.

- Ladder Logic helps make factories safer and more efficient. It lets engineers create step-by-step instructions for machines, track time-based processes, and quickly find and fix problems.

Ladder Logic is a Fundamental Programming Language for PLCs

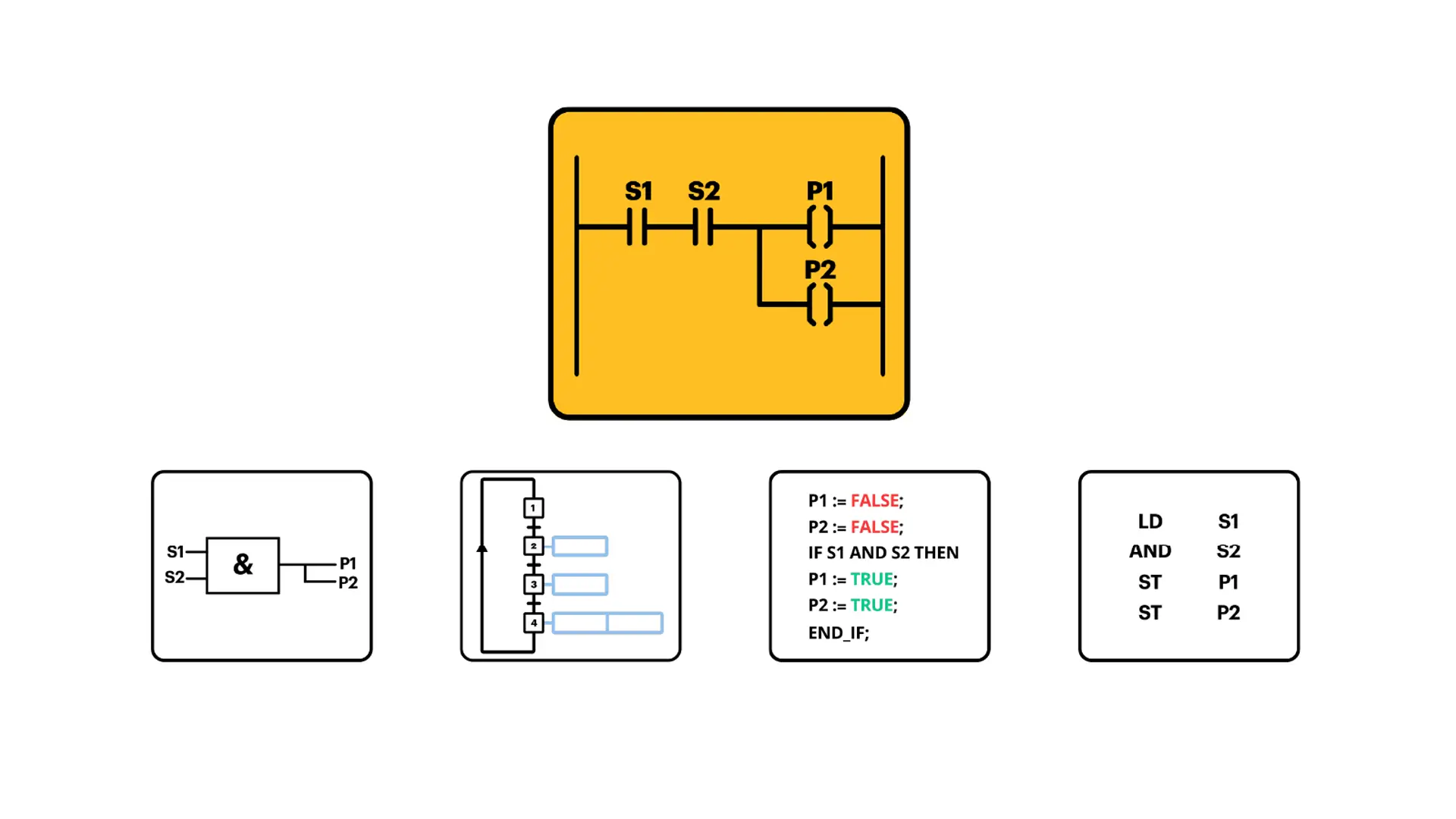

Ladder Logic is a fundamental programming language used for programmable logic controllers (PLCs). It is based on the concept of relay logic wiring diagrams and is commonly used to create programs for industrial automation and control systems. This graphical programming language employs various symbols to represent different logic functions, making it an essential tool for controlling machinery and processes in manufacturing and other industrial settings.

Ladder Logic Utilizes Relay-Style Logic

Ladder Logic is designed to mimic the traditional relay logic control systems used in industrial settings. It utilizes symbols that resemble the electrical control circuits of relay logic, allowing programmers to create intuitive and easy-to-understand control logic for PLCs. This approach simplifies the design and troubleshooting of control systems, making it a preferred choice for industrial automation applications.

Ladder Logic Employs Contacts and Coils

In Ladder Logic, contacts represent input conditions, while coils symbolize output actions. This representation closely mirrors the behavior of physical relays in traditional control systems. By using contacts and coils in a ladder diagram, programmers can create logical conditions and control sequences that govern the operation of industrial equipment and processes.

Ladder Logic Supports Boolean Logic Operations

Ladder Logic supports a range of Boolean logic operations, including AND, OR, and NOT functions. These operations enable programmers to create complex control algorithms by combining various input conditions and logical states. This capability is crucial for developing sophisticated control strategies that govern the behavior of industrial systems with precision and reliability.

Ladder Logic Facilitates Sequential Control

One of the key features of Ladder Logic is its ability to facilitate sequential control of industrial processes. By organizing the ladder diagram in a sequential manner, programmers can create step-by-step control sequences that dictate the operation of machinery and equipment. This sequential control capability is essential for optimizing production processes and ensuring efficient operation of industrial systems.

Ladder Logic Enables Timed and Counted Operations

Ladder Logic allows for the implementation of timed and counted operations within control programs. This functionality is vital for managing time-based processes and tracking the occurrence of events in industrial automation applications. By incorporating timers and counters into ladder diagrams, programmers can create precise control logic that meets the specific timing and counting requirements of industrial systems.

Ladder Logic Promotes Modular Programming

Modular programming is a key principle in Ladder Logic, allowing programmers to create reusable and scalable control logic. By breaking down complex control tasks into smaller, manageable modules, programmers can develop efficient and maintainable PLC programs. This modular approach enhances the flexibility and reusability of control logic, leading to more streamlined development and maintenance processes.

Ladder Logic Offers Visual Representation of Control Logic

The graphical nature of Ladder Logic provides a visual representation of control logic, making it easier for programmers and maintenance personnel to understand and troubleshoot PLC programs. The ladder diagram format allows for clear visualization of control sequences, input conditions, and output actions, facilitating efficient program comprehension and diagnostic activities in industrial environments.

Ladder Logic Supports Interlocking and Safety Functions

Interlocking and safety functions are integral aspects of industrial control systems, and Ladder Logic provides robust support for implementing these critical features. By utilizing interlocking techniques and safety relay logic in ladder diagrams, programmers can ensure the safe and reliable operation of machinery and processes, thereby enhancing workplace safety and preventing hazardous conditions.

Ladder Logic Enables Real-Time Monitoring and Control

PLC programs written in Ladder Logic enable real-time monitoring and control of industrial processes. The inherent speed and responsiveness of Ladder Logic programs allow for rapid execution of control logic, ensuring timely and accurate management of industrial equipment and systems. This real-time capability is essential for maintaining operational efficiency and responsiveness in dynamic industrial environments.

Ladder Logic Facilitates Diagnostics and Troubleshooting

The structured layout of Ladder Logic diagrams simplifies diagnostics and troubleshooting of PLC programs. By visually inspecting the ladder diagram and analyzing the logical flow of control logic, maintenance personnel can identify and rectify issues in industrial control systems more effectively. This diagnostic-friendly nature of Ladder Logic contributes to minimizing downtime and optimizing the reliability of industrial automation solutions.

Ladder Logic Continues to Evolve with Industry Advancements

As industrial automation technologies advance, Ladder Logic continues to evolve to meet the changing needs of modern manufacturing and control systems. With ongoing enhancements and refinements, Ladder Logic remains a versatile and adaptable programming language for PLCs, playing a pivotal role in driving the efficiency, productivity, and innovation of industrial processes across diverse sectors.

Ladder Logic serves as a cornerstone of industrial automation, empowering engineers and programmers to develop robust control strategies for a wide range of applications. Its intuitive graphical representation, support for diverse logic operations, and seamless integration with PLCs make it an indispensable tool for optimizing industrial processes and driving operational excellence. As industries continue to embrace automation and digitalization, the significance of Ladder Logic in shaping the future of manufacturing and control systems remains paramount.

Conclusion

In conclusion, understanding ladder logic is crucial for anyone working with programmable logic controllers (PLCs). This visual programming language simplifies the process of creating control systems, making it accessible to both experienced engineers and beginners. By grasping the fundamentals of ladder logic, individuals can effectively design, troubleshoot, and maintain PLC-based systems. With its roots in relay logic, ladder logic offers a familiar and intuitive approach to programming, enabling seamless integration with industrial automation processes. Embracing the 12 essential facts about ladder logic equips professionals with the knowledge needed to harness the full potential of PLCs, driving efficiency and innovation across diverse industrial applications.

FAQs

Q: What are the key benefits of using ladder logic for PLC programming?

A: Ladder logic simplifies the visualization of control systems, making it easier to understand and troubleshoot. It also allows for seamless integration with existing relay-based control systems, reducing the learning curve for engineers and technicians.

Q: How does ladder logic contribute to industrial automation processes?

A: Ladder logic serves as a foundational element in industrial automation, enabling the creation of efficient and reliable control systems for various applications, including manufacturing, automotive, and energy sectors. Its intuitive nature facilitates the seamless implementation of automation strategies, enhancing productivity and operational efficiency.

Was this page helpful?

Our commitment to delivering trustworthy and engaging content is at the heart of what we do. Each fact on our site is contributed by real users like you, bringing a wealth of diverse insights and information. To ensure the highest standards of accuracy and reliability, our dedicated editors meticulously review each submission. This process guarantees that the facts we share are not only fascinating but also credible. Trust in our commitment to quality and authenticity as you explore and learn with us.