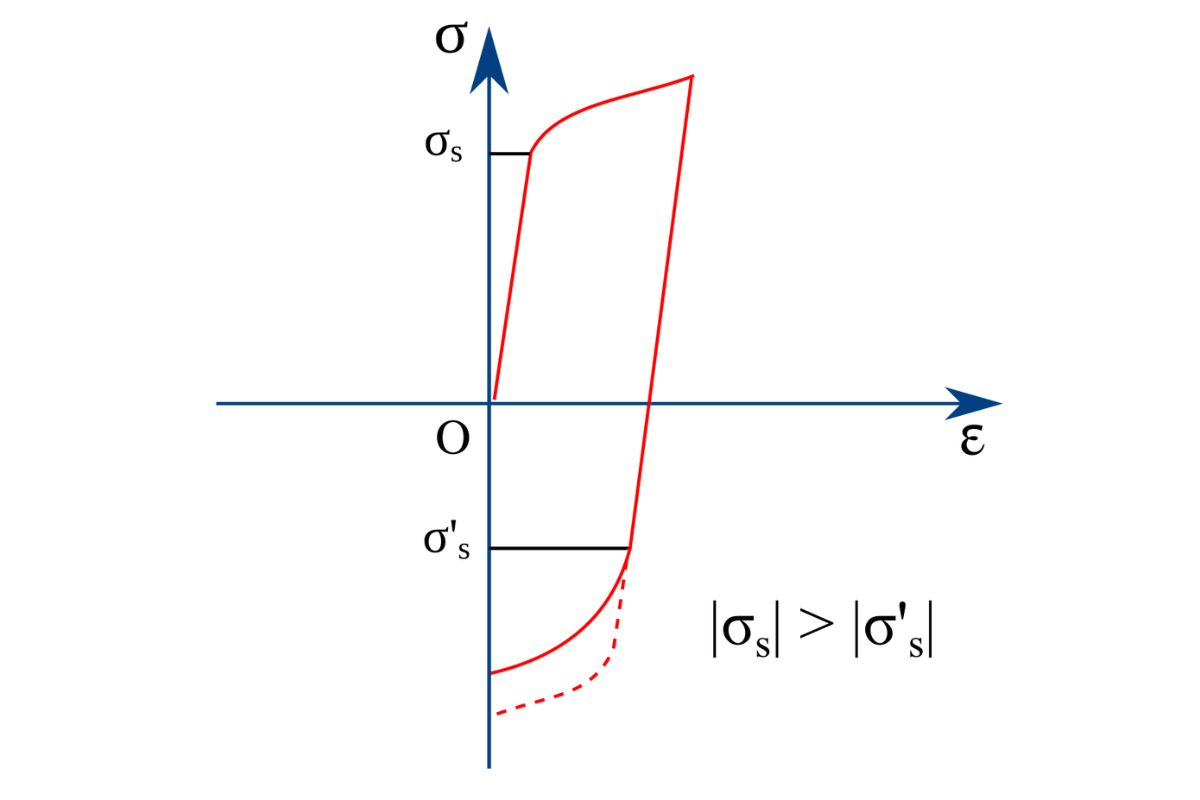

What is the Bauschinger Effect? The Bauschinger Effect refers to a phenomenon where the material's yield strength decreases after it has been plastically deformed in one direction and then subjected to reverse loading. Named after Johann Bauschinger, a German engineer, this effect is crucial in understanding material behavior, especially in metals. When a metal is stretched or compressed, its internal structure changes, making it easier to deform in the opposite direction. This can impact the design and durability of structures, machinery, and even everyday items. Understanding this effect helps engineers predict how materials will perform under different stress conditions, ensuring safety and reliability.

What is the Bauschinger Effect?

The Bauschinger Effect is a phenomenon observed in materials, particularly metals, where the material's yield strength in compression becomes different from its yield strength in tension after it has been plastically deformed. This effect is crucial in understanding material behavior under different loading conditions.

- Named after Johann Bauschinger, a German engineer who first observed this effect in 1881.

- It occurs due to changes in the internal structure of the material, such as dislocation movements.

- The effect is more pronounced in materials that have undergone significant plastic deformation.

- It is essential in the design of structures and components subjected to cyclic loading.

- The Bauschinger Effect can lead to unexpected failures if not properly accounted for in engineering designs.

How Does the Bauschinger Effect Impact Material Properties?

Understanding how the Bauschinger Effect impacts material properties helps engineers and scientists predict how materials will behave under different loading conditions.

- It causes a reduction in the yield strength of the material in the reverse direction of the initial loading.

- This reduction in yield strength can lead to earlier onset of plastic deformation in the reverse direction.

- The effect can influence the fatigue life of materials, making them more susceptible to failure under cyclic loading.

- It can also affect the material's ductility, making it more prone to brittle fracture.

- Engineers must consider the Bauschinger Effect when designing components that will experience repeated loading and unloading cycles.

Applications of the Bauschinger Effect in Engineering

The Bauschinger Effect has significant implications in various engineering fields, from automotive to aerospace industries.

- In the automotive industry, it helps in designing safer and more durable vehicle components.

- Aerospace engineers use knowledge of the Bauschinger Effect to ensure the structural integrity of aircraft components.

- It is crucial in the design of pressure vessels and pipelines subjected to fluctuating pressures.

- The effect is also considered in the manufacturing of metal forming processes, such as rolling and forging.

- Understanding this phenomenon helps in predicting the behavior of materials in crash simulations and impact analyses.

Factors Influencing the Bauschinger Effect

Several factors can influence the magnitude and nature of the Bauschinger Effect in materials.

- The type of material plays a significant role, with metals like steel and aluminum showing pronounced effects.

- The amount of plastic deformation the material has undergone affects the severity of the effect.

- The temperature at which the material is deformed can also influence the Bauschinger Effect.

- The strain rate, or the speed at which the material is deformed, impacts the effect's magnitude.

- The microstructure of the material, including grain size and phase distribution, can alter the Bauschinger Effect.

Experimental Methods to Study the Bauschinger Effect

Researchers use various experimental methods to study and quantify the Bauschinger Effect in materials.

- Tensile and compressive tests are commonly used to observe changes in yield strength.

- Cyclic loading tests help in understanding how repeated loading affects the material's behavior.

- Microstructural analysis using techniques like electron microscopy provides insights into dislocation movements.

- X-ray diffraction can be used to study changes in the material's crystal structure.

- Digital image correlation techniques help in measuring strain distribution during deformation.

Real-World Examples of the Bauschinger Effect

Real-world examples highlight the practical implications of the Bauschinger Effect in various industries.

- In bridge construction, engineers must account for the effect to ensure the longevity of the structure.

- The effect is considered in the design of earthquake-resistant buildings.

- In the oil and gas industry, it influences the design of drilling equipment and pipelines.

- The Bauschinger Effect is crucial in the manufacturing of railway tracks to prevent premature failure.

- It also plays a role in the development of sports equipment, such as bicycles and golf clubs, to enhance performance and durability.

Mitigating the Bauschinger Effect

Engineers and scientists have developed various strategies to mitigate the adverse effects of the Bauschinger Effect.

- Heat treatment processes can help in reducing the severity of the effect.

- Alloying elements are added to materials to improve their resistance to the Bauschinger Effect.

- Surface treatments, such as shot peening, can enhance the material's resistance to cyclic loading.

- Optimizing the material's microstructure through controlled processing techniques can mitigate the effect.

- Engineers use advanced simulation tools to predict and compensate for the Bauschinger Effect in their designs.

Future Research and Developments

Ongoing research aims to deepen the understanding of the Bauschinger Effect and develop new materials and techniques to counteract its impact.

- Researchers are exploring the use of nanomaterials to reduce the Bauschinger Effect.

- Advanced computational models are being developed to predict the effect more accurately.

- Studies are being conducted to understand the impact of the Bauschinger Effect on new materials, such as composites and high-entropy alloys.

- Collaborative efforts between academia and industry aim to develop innovative solutions to mitigate the effect.

- Future advancements in material science and engineering will continue to improve our ability to manage the Bauschinger Effect in various applications.

The Bauschinger Effect's Impact

Understanding the Bauschinger Effect is crucial for anyone involved in materials science or engineering. This phenomenon, where materials exhibit different stress-strain behaviors under reversed loading, plays a significant role in designing and manufacturing durable products. Knowing how materials will react under various conditions helps engineers create safer, more efficient structures.

The Bauschinger Effect isn't just a technical term; it's a key factor in many industries, from automotive to aerospace. By grasping its implications, professionals can better predict material performance, leading to innovations and improvements in product longevity and safety.

So, next time you encounter a discussion about material stress and strain, you'll know the Bauschinger Effect is a vital piece of the puzzle. Understanding this concept not only enhances your knowledge but also equips you to make informed decisions in the field of material science.

Was this page helpful?

Our commitment to delivering trustworthy and engaging content is at the heart of what we do. Each fact on our site is contributed by real users like you, bringing a wealth of diverse insights and information. To ensure the highest standards of accuracy and reliability, our dedicated editors meticulously review each submission. This process guarantees that the facts we share are not only fascinating but also credible. Trust in our commitment to quality and authenticity as you explore and learn with us.