Kanthal is a name that sparks curiosity, especially among those interested in materials science and engineering. But what exactly is Kanthal? Kanthal is a brand of iron-chromium-aluminum (FeCrAl) alloys used in a wide range of applications due to its high resistance to oxidation and electrical heating properties. This unique material is often found in heating elements, industrial furnaces, and even some household appliances. Its ability to withstand extreme temperatures makes it a go-to choice for many industries. Whether you're a student, a DIY enthusiast, or a professional engineer, understanding the ins and outs of Kanthal can be incredibly beneficial. Ready to dive into some intriguing facts about this versatile alloy? Let's get started!

Key Takeaways:

- Kanthal is a super durable and heat-resistant alloy used in everything from vaping devices to space exploration. It's like the superhero of metals, saving the day in extreme conditions!

- With its high melting point and resistance to corrosion, Kanthal is like the ultimate multitasker, working in industries from aerospace to jewelry-making. It's the go-to material for tough jobs!

What is Kanthal?

Kanthal is a brand name for a family of iron-chromium-aluminum (FeCrAl) alloys used in a wide range of industrial applications. Known for its high resistance to oxidation and heat, Kanthal is a popular choice in various industries.

- Kanthal was first developed in Sweden in the 1930s by the Kanthal Corporation.

- The name "Kanthal" is derived from the Swedish words "Kant" (edge) and "Hall" (hall), symbolizing the cutting-edge technology.

- Kanthal alloys are primarily composed of iron, chromium, and aluminum, making them highly resistant to oxidation.

- These alloys can withstand temperatures up to 1400°C (2552°F), making them ideal for high-temperature applications.

- Kanthal is often used in heating elements for electric furnaces, kilns, and other high-temperature equipment.

- The material is also used in the production of resistors and other electronic components due to its stable electrical resistance.

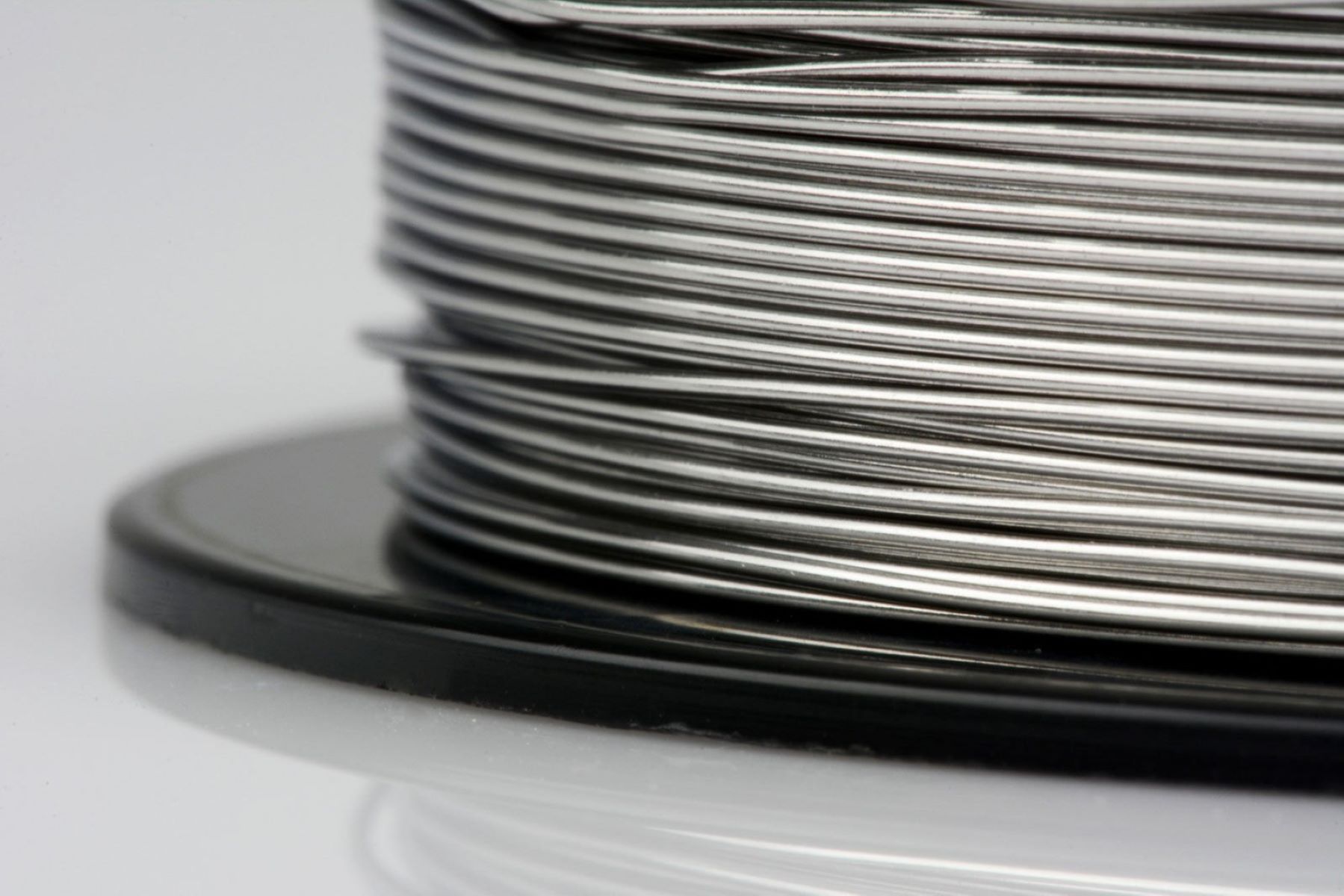

- Kanthal wire is commonly used in vaping devices because it heats up quickly and maintains a consistent temperature.

- The alloy is also used in the automotive industry for components like catalytic converters and exhaust systems.

- Kanthal is known for its long lifespan, even under extreme conditions, reducing the need for frequent replacements.

- The material is highly resistant to corrosion, making it suitable for use in harsh environments.

Applications of Kanthal

Kanthal's unique properties make it suitable for a variety of applications across different industries. Here are some of the most common uses.

- In the glass industry, Kanthal is used in furnaces for melting and shaping glass.

- The ceramics industry utilizes Kanthal in kilns for firing pottery and other ceramic products.

- Kanthal is used in the production of metal alloys, where high temperatures are required for melting and mixing metals.

- In the chemical industry, Kanthal is used in reactors and other equipment that must withstand high temperatures and corrosive environments.

- The food industry uses Kanthal in ovens and other cooking equipment that require precise temperature control.

- Kanthal is also used in the textile industry for heat-setting fabrics and other processes that require high temperatures.

- The aerospace industry uses Kanthal in components that must withstand extreme temperatures and harsh conditions.

- Kanthal is used in the production of solar panels, where high temperatures are needed to manufacture photovoltaic cells.

- The material is also used in the production of semiconductors, which require precise temperature control during manufacturing.

- Kanthal is used in medical equipment, such as sterilizers and autoclaves, that require high temperatures for sterilization.

Benefits of Using Kanthal

Kanthal offers several advantages that make it a preferred material in many industries. Here are some of the key benefits.

- Kanthal has a high melting point, which makes it suitable for high-temperature applications.

- The material is highly resistant to oxidation, which extends its lifespan and reduces maintenance costs.

- Kanthal has a stable electrical resistance, making it ideal for use in electronic components.

- The material heats up quickly and maintains a consistent temperature, which is important for applications that require precise temperature control.

- Kanthal is highly resistant to corrosion, making it suitable for use in harsh environments.

- The material is durable and long-lasting, reducing the need for frequent replacements.

- Kanthal is easy to work with, making it a versatile material for a wide range of applications.

- The material is cost-effective, offering a good balance of performance and price.

- Kanthal is environmentally friendly, as it can be recycled and reused.

- The material is available in a variety of forms, including wire, ribbon, and strip, making it suitable for different applications.

Interesting Facts About Kanthal

Beyond its technical specifications and applications, Kanthal has some intriguing aspects worth noting.

- Kanthal was originally developed as a replacement for nichrome, another high-resistance alloy.

- The development of Kanthal revolutionized the heating element industry, offering a more durable and efficient alternative.

- Kanthal is used in some musical instruments, such as electric guitar strings, due to its durability and resistance to corrosion.

- The material is also used in art installations, where its ability to withstand high temperatures is a key advantage.

- Kanthal is used in scientific research, particularly in experiments that require high temperatures and precise control.

- The material has been used in space exploration, where its resistance to extreme temperatures and harsh conditions is crucial.

- Kanthal is used in the production of fireworks, where its high melting point and resistance to oxidation are important.

- The material is also used in the production of jewelry, particularly in pieces that require high durability and resistance to corrosion.

- Kanthal is used in the production of high-performance sports equipment, such as racing car components and high-end bicycles.

- The material is also used in the production of high-end kitchen appliances, where its durability and resistance to high temperatures are key advantages.

The Final Word on Kanthal

Kanthal, a versatile material, has proven its worth in various industries. From its high-temperature resistance to its durability, it’s clear why it’s a go-to choice for many applications. Whether you’re into electronics, heating elements, or even vaping, Kanthal offers reliability and performance. Its unique composition of iron, chromium, and aluminum gives it the edge over other materials. Plus, its ability to withstand oxidation and corrosion makes it a long-lasting option.

Understanding these key facts about Kanthal can help you make informed decisions for your projects. Whether you’re a hobbyist or a professional, knowing the benefits and uses of Kanthal can save you time and money. So, next time you’re working on a project that requires a robust and reliable material, consider Kanthal. It’s a choice you won’t regret.

Frequently Asked Questions

Was this page helpful?

Our commitment to delivering trustworthy and engaging content is at the heart of what we do. Each fact on our site is contributed by real users like you, bringing a wealth of diverse insights and information. To ensure the highest standards of accuracy and reliability, our dedicated editors meticulously review each submission. This process guarantees that the facts we share are not only fascinating but also credible. Trust in our commitment to quality and authenticity as you explore and learn with us.