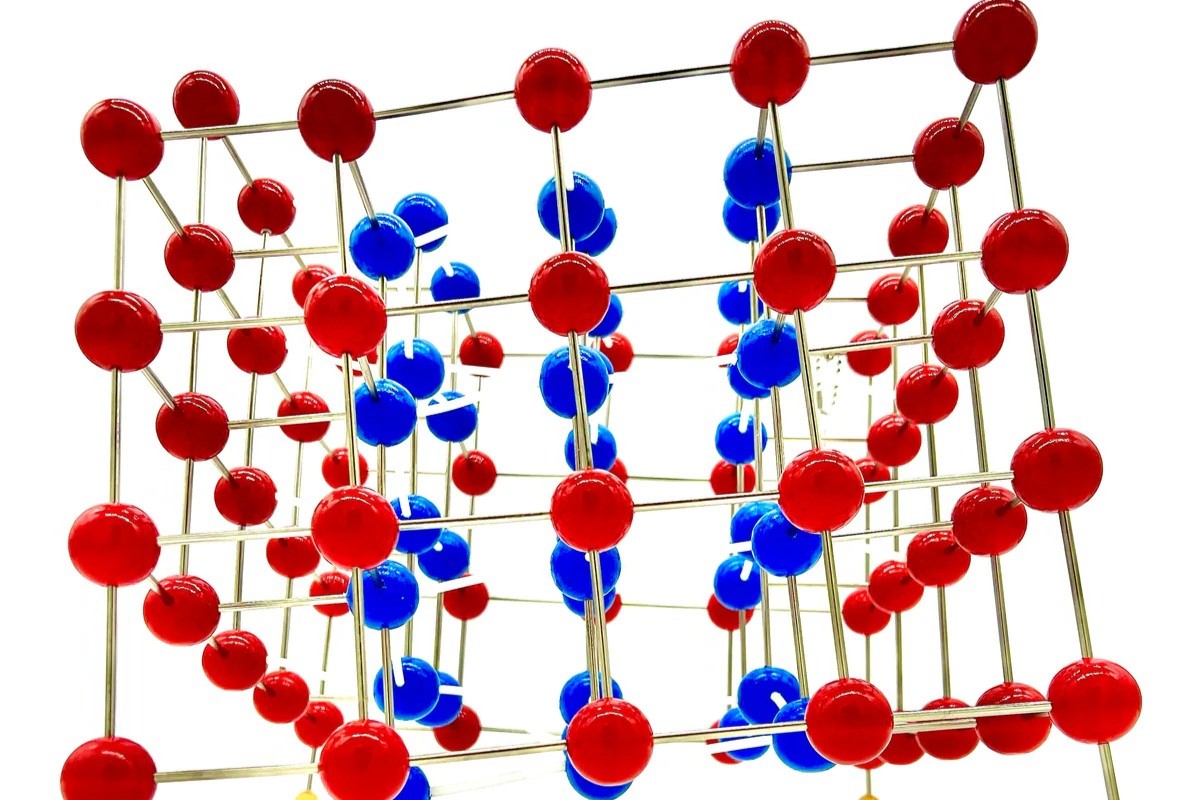

What is screw dislocation? Screw dislocation is a type of defect in a crystal structure where atoms are misaligned, creating a spiral ramp around a central line. This defect plays a crucial role in the plastic deformation of materials. Understanding screw dislocation helps scientists and engineers improve the strength and durability of metals and other materials. Imagine twisting a stack of paper so that one side shifts up while the other stays in place. That twist represents a screw dislocation in a crystal lattice. These defects can affect the material's properties, like how easily it can be shaped or how it responds to stress.

What is Screw Dislocation?

Screw dislocation is a type of defect in the crystal structure of materials. It plays a crucial role in the mechanical properties of metals and other crystalline solids. Here are some fascinating facts about screw dislocation.

-

Screw dislocation involves a helical ramp of atoms around a central line. This unique structure differentiates it from other types of dislocations.

-

It was first described by Geoffrey Ingram Taylor in 1934. Taylor's work laid the foundation for modern dislocation theory.

-

Screw dislocations can move through a crystal lattice. This movement allows materials to deform under stress.

-

They are characterized by a Burgers vector parallel to the dislocation line. This vector helps in identifying the nature and direction of the dislocation.

-

Screw dislocations can form during crystal growth. As atoms are added to a growing crystal, dislocations can naturally occur.

-

They contribute to the plastic deformation of materials. This means they help materials bend and stretch without breaking.

How Screw Dislocation Affects Material Properties

Understanding how screw dislocation impacts material properties can help in designing stronger and more durable materials.

-

Screw dislocations increase the strength of materials. They create obstacles that make it harder for other dislocations to move.

-

They can lead to work hardening. As a material is deformed, dislocations multiply and interact, making the material harder.

-

Screw dislocations can cause anisotropy in materials. This means the material's properties can vary depending on the direction of the applied force.

-

They play a role in the ductility of metals. Ductility is the ability of a material to stretch without breaking, and screw dislocations facilitate this process.

-

Screw dislocations can affect electrical conductivity. In some materials, dislocations can scatter electrons, reducing conductivity.

-

They can influence the thermal properties of materials. Dislocations can scatter phonons, affecting heat transfer.

Observing and Measuring Screw Dislocation

Scientists use various techniques to observe and measure screw dislocations in materials.

-

Transmission electron microscopy (TEM) is a common method. TEM allows scientists to see dislocations at the atomic level.

-

X-ray diffraction can also be used. This technique helps in identifying the presence and density of dislocations.

-

Atomic force microscopy (AFM) provides surface images of dislocations. AFM can measure the topography of a material's surface with high precision.

-

Dislocation density is an important parameter. It indicates the number of dislocations in a given volume of material.

-

Etch pits can reveal dislocations. When a crystal is etched, dislocations can appear as tiny pits on the surface.

-

Computer simulations help in studying dislocations. These simulations can model the behavior of dislocations under various conditions.

Applications and Implications of Screw Dislocation

Screw dislocations have significant implications in various fields, from materials science to engineering.

-

They are crucial in the development of high-strength alloys. Understanding dislocations helps in designing alloys with superior mechanical properties.

-

Screw dislocations are important in semiconductor technology. They can affect the performance of semiconductor devices.

-

They play a role in the manufacturing of nanomaterials. Controlling dislocations can lead to the production of materials with unique properties.

-

Screw dislocations are studied in geology. They can influence the mechanical behavior of minerals and rocks.

-

They are relevant in the field of metallurgy. Metallurgists study dislocations to improve metal processing techniques.

-

Screw dislocations are important in the study of fatigue. Understanding how dislocations move and interact can help in predicting material failure.

Final Thoughts on Screw Dislocation

Screw dislocations play a huge role in materials science. They affect the strength, ductility, and overall behavior of metals and other materials. Understanding these defects helps engineers design stronger, more reliable products. From the atomic level to large-scale applications, screw dislocations are everywhere. They’re key to innovations in technology and industry.

By grasping the basics of screw dislocations, you gain insight into how materials work. This knowledge can lead to better decisions in manufacturing and engineering. So next time you see a metal object, remember the tiny imperfections that make it strong and useful.

Keep exploring the world of materials science. There’s always more to learn about the hidden forces shaping our everyday objects. Whether you’re a student, engineer, or curious mind, the study of screw dislocations offers endless fascination.

Was this page helpful?

Our commitment to delivering trustworthy and engaging content is at the heart of what we do. Each fact on our site is contributed by real users like you, bringing a wealth of diverse insights and information. To ensure the highest standards of accuracy and reliability, our dedicated editors meticulously review each submission. This process guarantees that the facts we share are not only fascinating but also credible. Trust in our commitment to quality and authenticity as you explore and learn with us.