The Sol-Gel process is a fascinating and versatile technique used in materials science and chemistry. It involves the transformation of a solution into a solid material through a series of chemical reactions. This method has been widely studied and applied in various industries, such as electronics, optics, and biomedical engineering.

But beyond its practical implications, the Sol-Gel process has a rich and enigmatic nature that leaves many researchers intrigued. In this article, we will delve into the world of Sol-Gel and explore 14 fascinating facts about this process. From its historical origins to its unique properties, each fact sheds light on the complexity and potential of this remarkable chemical transformation.

So, get ready to uncover the mysteries behind Sol-Gel and dive into the captivating world of materials science.

Key Takeaways:

- The sol-gel process transforms solutions into durable materials, enhancing surfaces and creating nanoscale materials with unique properties for applications in medicine, electronics, and more.

- Sol-gel coatings offer a greener alternative to traditional methods, protecting against chemical and thermal stresses and shaping advancements in various fields, from aerospace to electronics.

The sol-gel process was first discovered in the late 1800s.

Long before its potential applications were explored, the sol-gel process was first observed by Eberhard Schulz and Friedrich Funk in the late 1800s. It wasn’t until much later that scientists realized the diverse uses and advantages of this technique.

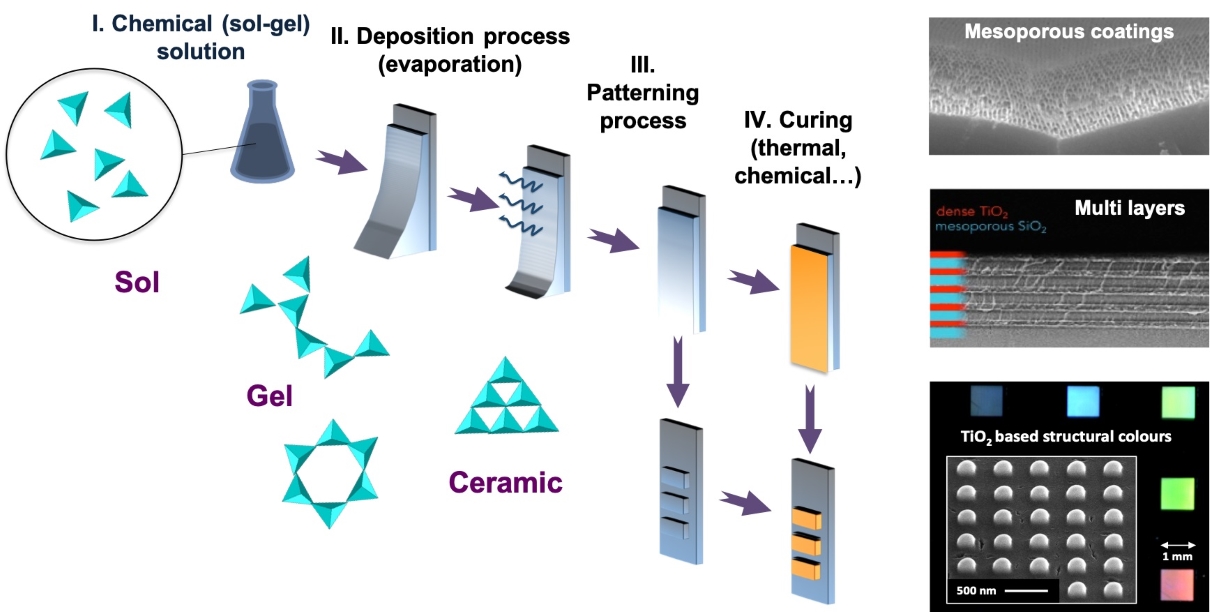

The sol-gel process involves the transition of a solution to a solid material.

Unlike other methods that require high temperatures and pressure, the sol-gel process allows for the controlled transformation of a sol (a colloidal suspension) to a gel and ultimately to a solid material.

Sol-gel coatings can enhance the performance and functionality of surfaces.

By applying sol-gel coatings, surfaces can become more durable, corrosion-resistant, and even self-cleaning. These coatings have applications in various industries, including automotive, aerospace, and electronics.

Sol-gel-derived materials exhibit unique optical properties.

Materials produced through the sol-gel process can possess a wide range of optical properties, including transparency, luminescence, and refractivity. This makes them valuable in the development of optical fibers, lenses, and photonic devices.

Sol-gel process enables the synthesis of nanoscale materials.

The sol-gel process allows for the precise control of particle size, making it an ideal method for producing nanoparticles, nanocomposites, and nanostructured materials with enhanced properties and applications in fields like medicine and electronics.

Sol-gel materials can serve as effective catalysts.

Through careful doping or functionalization, sol-gel materials can have catalytic properties, making them valuable in chemical reactions, fuel cells, and environmental remediation.

Sol-gel process can be used to create bioactive materials.

Sol-gel-derived materials can be tailored to exhibit bioactive properties, making them suitable for applications such as drug delivery systems, tissue engineering, and biosensors.

Sol-gel films can be used for optical data storage.

By depositing sol-gel films on appropriate substrates, it is possible to create media for optical data storage, which can store and retrieve large amounts of information efficiently.

Sol-gel process offers a greener alternative to traditional methods.

Compared to traditional methods, the sol-gel process is relatively environmentally friendly as it operates at lower temperatures and does not require harsh chemicals or excess energy consumption.

Sol-gel materials can be used in energy storage and conversion.

The unique properties of sol-gel-derived materials make them suitable for applications in energy storage devices like batteries and supercapacitors, as well as in the development of solar cells and fuel cells.

Sol-gel process can lead to the creation of hybrid materials.

By combining organic and inorganic precursors in the sol-gel process, hybrid materials with enhanced properties can be synthesized. This opens up possibilities in areas such as sensors, optoelectronics, and catalysis.

Sol-gel technique can be used for fabricating thin films.

The sol-gel method allows for the deposition of thin films onto various substrates, enabling the production of coatings with controlled thickness and properties for applications ranging from electronics to protective layers.

The sol-gel process is a versatile tool for tailoring material properties.

With careful selection of precursors, processing conditions, and additives, the sol-gel process offers a highly customizable approach to create materials with desired properties, allowing researchers to fine-tune materials for specific applications.

Sol-gel coatings can protect against chemical and thermal stresses.

Sol-gel-derived coatings have excellent resistance to chemicals and high temperatures, making them suitable for protecting materials in harsh environments like aerospace components, industrial equipment, and automotive parts.

These 14 enigmatic facts about sol-gel process highlight its wide range of applications and potential. From creating nanostructured materials to enhancing surface properties and tailoring material characteristics, the sol-gel process is a fascinating technique that continues to shape advancements in various fields.

Conclusion

In conclusion, the Sol-Gel process is a fascinating technique that has revolutionized the field of material science and chemistry. Its unique properties and applications have contributed to various industries, ranging from electronics and optoelectronics to medicine and cosmetics. Through careful manipulation of the sol-gel parameters, scientists have been able to create materials with precise control over their structure, size, and properties.The Sol-Gel process offers numerous advantages such as low processing temperatures, the ability to create thin films and coatings, and the incorporation of various dopants and additives. It has also emerged as an environmentally friendly and cost-effective alternative to traditional manufacturing methods.As research and development in the field of sol-gel chemistry continue to advance, we can expect even more exciting applications and discoveries. The Sol-Gel process holds great promise in areas such as energy storage, catalysis, and sensors, making it an essential tool for future scientific advancements.

FAQs

1. What is the Sol-Gel process?

The Sol-Gel process is a versatile technique used to synthesize ceramic and glass materials through the controlled hydrolysis and condensation of metal alkoxides or metal chlorides in a liquid solution called the sol.

2. What are some applications of the Sol-Gel process?

The Sol-Gel process finds applications in various fields, including electronics, optics, biomedicine, and coatings. It is used to fabricate thin films, optical fibers, ceramic composites, and bioactive materials.

3. How does the Sol-Gel process differ from traditional synthesis methods?

Unlike conventional methods, the Sol-Gel process allows for the synthesis of materials at low temperatures and produces products with a high degree of homogeneity. It also offers better control over the material’s structure and properties.

4. Is the Sol-Gel process environmentally friendly?

Yes, the Sol-Gel process is considered environmentally friendly as it generates minimal waste and does not require harsh chemicals or high temperatures typically associated with other synthesis methods.

5. What are the advantages of using the Sol-Gel process?

Some advantages of the Sol-Gel process include the ability to create thin films and coatings, the incorporation of dopants and additives, and the production of materials with tailored properties and controlled porosity.

Unravel the enigmatic world of sol-gel processes and explore their fascinating applications. From protective coatings that shield against harsh environments to groundbreaking chemical processes like the Bayer process, these innovative techniques are transforming industries. Dive into the captivating realm of men's fashion with our curated selection of the best trench coats, perfect for elevating your style game. Join us on this thrilling journey of discovery as we uncover the secrets behind these cutting-edge technologies and trends that are shaping our world in remarkable ways.

Was this page helpful?

Our commitment to delivering trustworthy and engaging content is at the heart of what we do. Each fact on our site is contributed by real users like you, bringing a wealth of diverse insights and information. To ensure the highest standards of accuracy and reliability, our dedicated editors meticulously review each submission. This process guarantees that the facts we share are not only fascinating but also credible. Trust in our commitment to quality and authenticity as you explore and learn with us.