Underwater welding is a fascinating and dangerous profession that combines the skills of welding with the challenges of working in a submerged environment. While it may not be a well-known field, underwater welders play a critical role in maintaining and repairing structures such as oil rigs, bridges, and ships. The job requires a unique set of skills and a high level of expertise to work in the complex underwater conditions.

In this article, we will explore 19 fascinating facts about underwater welders. From the risks they face to the specialized training they undergo, these facts will give you a glimpse into the world of underwater welding and the individuals who brave the depths to keep our infrastructure intact. So, let’s dive deeper and uncover some intriguing details about this intriguing profession.

Key Takeaways:

- Underwater welding, also known as hyperbaric welding, is a challenging yet lucrative profession that requires rigorous training, specialized equipment, and a commitment to safety in extreme underwater conditions.

- Underwater welders play a crucial role in maintaining and repairing underwater structures, contributing to environmental preservation, and have diverse career opportunities beyond industrial settings, such as scientific research and film production.

Underwater welding is also known as hyperbaric welding.

Underwater welding, commonly referred to as hyperbaric welding, is a specialized technique that involves welding underwater. It is widely used in various industries, including offshore oil and gas, marine construction, and underwater repairs.

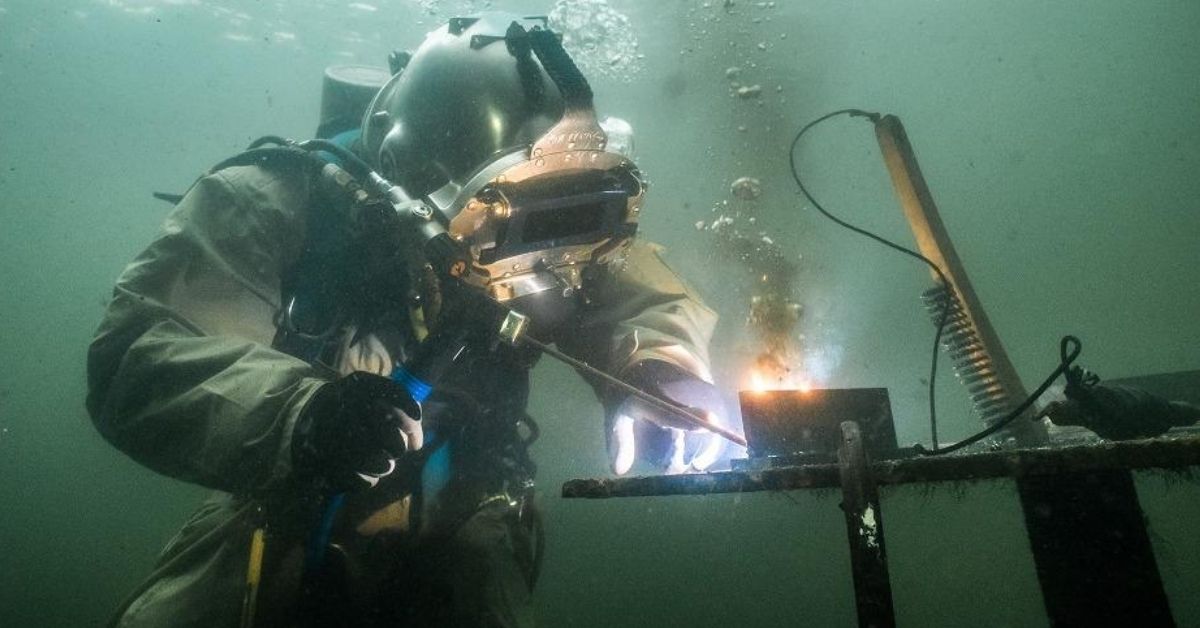

Underwater welders work in extreme conditions.

Underwater welders face challenging environments, including high pressure, limited visibility, and the risk of electric shock. They require specialized training and equipment to ensure their safety and the successful completion of their tasks.

Underwater welding has been around for over 70 years.

The practice of underwater welding dates back to the 1940s when it was first used during World War II for ship repairs. Since then, it has evolved significantly, with advancements in technology and safety procedures.

Underwater welders undergo rigorous training.

Becoming an underwater welder requires a combination of diving certification and welding qualifications. The training involves learning various diving techniques, understanding underwater welding equipment, and mastering welding techniques suitable for underwater conditions.

Underwater welders often work in saturation diving systems.

Many underwater welding operations are conducted using saturation diving systems. These systems allow divers to work at great depths for prolonged periods by maintaining a constant pressure environment. This minimizes the risk of decompression sickness.

Underwater welding can be performed using different techniques.

There are two main techniques used in underwater welding: wet welding and dry welding. Wet welding involves welding directly in the water, while dry welding is performed in specially constructed habitats or chambers.

Underwater welders use specialized welding equipment.

To perform their tasks effectively, underwater welders use specialized equipment designed for underwater welding. This includes waterproof electrodes, diving helmets, and welding machines that can operate in wet or dry environments.

Underwater welders often face diving hazards.

Aside from the risks associated with welding, underwater welders also encounter various diving hazards such as marine life, entanglement risks, and underwater currents. Safety protocols and proper training are essential to mitigate these risks.

Underwater welding plays a crucial role in maintenance and repairs.

Underwater welders are integral to the maintenance and repair of underwater structures, including ships, offshore platforms, pipelines, and dams. Their skills are necessary to ensure the structural integrity and efficiency of these important infrastructure components.

Underwater welding can be highly lucrative.

Due to the specialized nature of their work and the risks involved, underwater welders often command high salaries. Their earning potential can be influenced by factors such as experience, qualifications, location, and the complexity of the project.

Underwater welding requires meticulous planning.

Before starting any underwater welding project, thorough planning is crucial. Factors such as tides, currents, weather conditions, and equipment maintenance must be taken into account to ensure a safe and successful operation.

Underwater welders need to be physically fit.

The demanding nature of underwater welding requires divers to be in excellent physical condition. They must possess strong swimming skills, endurance, and the ability to work in strenuous underwater environments.

Underwater welders may work in remote locations.

Many underwater welding projects take place in remote locations, such as offshore oil rigs or deep-sea installations. This often means extended periods away from home and living in temporary accommodations.

Underwater welders contribute to environmental preservation.

Underwater welders are responsible for maintaining and repairing structures that play a role in environmental preservation. This includes fixing underwater pipelines that transport natural resources and ensuring the stability of marine habitats.

Underwater welding can provide diverse career opportunities.

Underwater welding opens up a range of career opportunities beyond industrial settings. Some underwater welders choose to work in scientific research, underwater archaeology, or film production, utilizing their skills in unique and exciting ways.

Underwater welders must adhere to strict safety protocols.

Due to the risks involved, safety is of paramount importance in underwater welding. Underwater welders strictly adhere to safety protocols, including pre-dive checks, continuous monitoring of equipment, and emergency procedures.

Underwater welders often work in teams.

Underwater welding projects typically involve teams of divers and support personnel. Effective communication and teamwork are crucial for carrying out tasks safely and efficiently in the underwater environment.

Underwater welders have opportunities for career progression.

As underwater welders gain experience and additional qualifications, they can advance in their careers. This may include becoming diving supervisors, instructors, or pursuing managerial roles within the industry.

Underwater welding is a physically and mentally challenging profession.

Underwater welding requires a unique combination of physical stamina, mental fortitude, and technical expertise. It is a profession that demands continuous learning, adaptability, and a commitment to personal and professional growth.

Conclusion

The profession of an underwater welder is both fascinating and challenging. These skilled individuals play a crucial role in various industries such as construction, maintenance, and salvage operations. With the ability to work in extreme conditions and depths, underwater welders possess a unique skill set that sets them apart from other welders. Their work is not only technically demanding but also carries significant risks and requires extensive training and experience.

Being an underwater welder offers a thrilling career with the opportunity to explore the depths of the ocean and work on complex projects. It requires a combination of welding expertise, knowledge of dive techniques, and a strong understanding of underwater physics. With the increasing demand for underwater welding services, it is a field that provides plenty of opportunities for growth and advancement.

Overall, the world of underwater welding is truly captivating, and those involved in this profession are essential in maintaining and building structures beneath the sea surface.

FAQs

1. What is an underwater welder?

An underwater welder is a professional who performs welding tasks in underwater environments. They work in various industries such as offshore oil and gas, shipbuilding, bridge construction, and underwater infrastructure maintenance.

2. What skills are required to become an underwater welder?

To become an underwater welder, you need to possess excellent welding skills, knowledge of diving techniques, understanding of underwater physics, and the ability to work in challenging environments. Additionally, certifications in commercial diving and underwater welding are typically required.

3. What are the risks associated with underwater welding?

Underwater welding involves potential risks such as electrical shocks, decompression sickness, hypothermia, and entanglement hazards. Adequate training, safety protocols, and proper equipment are necessary to mitigate these risks.

4. How deep do underwater welders work?

Underwater welders can work at varying depths depending on the project requirements. They may work in shallow waters, such as in harbors and inland waterways, or in deep sea environments, reaching depths of several hundred feet.

5. Can anyone become an underwater welder?

Not anyone can become an underwater welder. It requires a combination of specialized skills, certifications, and experience. Prospective underwater welders typically undergo extensive training and must meet certain physical and medical requirements.

Was this page helpful?

Our commitment to delivering trustworthy and engaging content is at the heart of what we do. Each fact on our site is contributed by real users like you, bringing a wealth of diverse insights and information. To ensure the highest standards of accuracy and reliability, our dedicated editors meticulously review each submission. This process guarantees that the facts we share are not only fascinating but also credible. Trust in our commitment to quality and authenticity as you explore and learn with us.