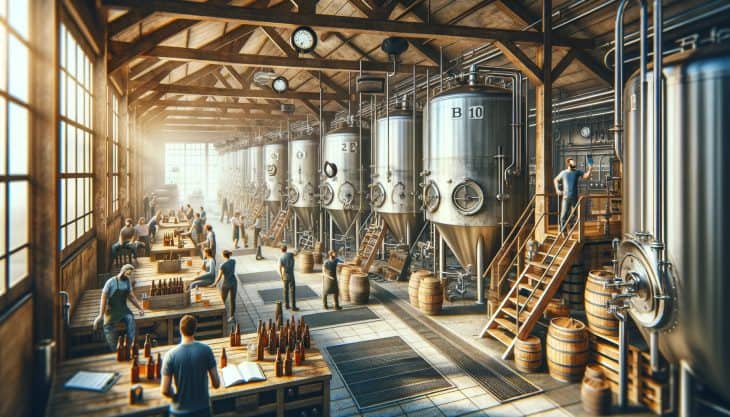

Are you a beer enthusiast looking to expand your knowledge about brewing? If so, you’ve come to the right place. This article will provide you with 10 fascinating facts about the world of 10 BBL (barrel) brewing. Whether you’re a homebrewer, a beer connoisseur, or simply curious about the process, these insights will give you a deeper understanding of the art and science behind brewing 10 BBL batches. So, grab a cold one, sit back, and let’s dive into the wonderful world of 10 BBL brewing!

Key Takeaways:

- BBL, or Barrel, is a standard unit for measuring beer production, allowing breweries to compare volumes, track inventory, and plan for expansion, reflecting the global impact of beer crafting.

- The term “BBL” originated from wooden beer barrels and has evolved alongside brewing technology, symbolizing the rich tradition and innovation within the art of beer crafting.

BBL, or Barrel, is a Unit of Measurement for Beer Production.

BBL, short for “barrel,” is a standard unit of measurement used in the brewing industry to quantify the volume of beer produced. One barrel is equivalent to 31 gallons or 117.347 liters. This unit is commonly employed by breweries and has become a fundamental aspect of the beer production process.

The Term “BBL” Originated from the Wooden Barrels Initially Used for Beer Storage and Transportation.

The use of the term “BBL” can be traced back to the traditional practice of storing and transporting beer in wooden barrels. Over time, the term has persisted as a standard unit of measurement, even as modern brewing methods and storage containers have evolved. The historical significance of this term underscores its enduring relevance in the brewing industry.

BBLs Provide a Standardized Method for Comparing Beer Production Across Breweries.

By utilizing BBLs as a unit of measurement, breweries can accurately compare their production volumes with those of other breweries. This standardized approach facilitates industry-wide benchmarking and analysis, enabling breweries to assess their market positions and production capabilities effectively.

The BBL Measurement is Essential for Calculating Beer Excise Taxes and Regulatory Compliance.

Government agencies often employ BBL measurements to determine excise taxes and ensure regulatory compliance within the brewing industry. This standardized unit of measurement plays a crucial role in tax assessment and regulatory oversight, contributing to the overall governance of beer production and distribution.

BBLs Are Utilized to Track and Monitor Beer Inventory Levels Within Breweries.

Breweries rely on BBL measurements to monitor their beer inventory levels accurately. By quantifying production and stock levels in BBLs, breweries can effectively manage their supply chains, forecast demand, and optimize inventory control processes, contributing to efficient brewery operations.

BBLs Enable Breweries to Evaluate and Plan for Production Capacity and Expansion.

By leveraging BBL measurements, breweries can assess their production capacities and plan for potential expansions. This standardized unit of measurement serves as a foundational element for breweries to analyze their growth trajectories, make informed expansion decisions, and strategically scale their operations.

Understanding BBLs is Integral for Professionals in the Brewing and Beverage Industry.

Professionals within the brewing and beverage industry must possess a comprehensive understanding of BBLs and their significance. Whether involved in production, distribution, or regulatory compliance, a firm grasp of BBL measurements is essential for navigating the intricacies of the industry and making informed business decisions.

BBLs Reflect the Scale and Impact of Beer Production on a Global Scale.

As breweries worldwide continue to produce vast quantities of beer, the utilization of BBLs underscores the scale and impact of beer production on a global level. This unit of measurement serves as a testament to the substantial volumes of beer generated by breweries across diverse regions, highlighting the industry’s far-reaching influence.

The Evolution of BBL Measurements Aligns with the Advancements in Brewing Technology and Practices.

Over time, BBL measurements have evolved alongside the advancements in brewing technology and practices. From traditional wooden barrels to modern stainless steel tanks, the adaptability of BBLs as a measurement unit reflects the dynamic progression of brewing methods and the continual innovation within the industry.

BBLs Symbolize the Rich Tradition and Innovation Embedded in the Art of Beer Crafting.

Within the rich tapestry of beer crafting, BBLs symbolize the seamless integration of tradition and innovation. As breweries honor time-honored brewing practices while embracing cutting-edge technologies, the enduring relevance of BBLs encapsulates the timeless legacy and forward-looking spirit of the beer crafting tradition.

Conclusion

These 10 BBL facts shed light on the fascinating world of brewing beer. From the history and science behind the process to the modern-day techniques and equipment, it’s clear that brewing is an intricate and evolving art. Whether you’re a seasoned brewmaster or a curious enthusiast, understanding the nuances of the 10 BBL brewing system and the craft itself can deepen your appreciation for this time-honored tradition. As the craft beer industry continues to flourish, these facts serve as a reminder of the skill, dedication, and innovation that go into creating the perfect pint.

FAQs

What does BBL stand for in brewing?

BBL stands for “barrel” and is a unit of measurement commonly used in the brewing industry to quantify the volume of beer produced. One BBL is equivalent to 31 gallons or 117.3 liters.

What is a 10 BBL brewing system?

A 10 BBL brewing system refers to the equipment and infrastructure used to produce 10 barrels of beer in a single batch. This setup typically includes a mash tun, brew kettle, fermenters, and other essential components for the brewing process.

How long does it take to brew 10 BBL of beer?

The brewing timeline for a 10 BBL batch can vary, but it generally takes around 4 to 6 hours for the actual brewing process. However, the entire production cycle, including fermentation and conditioning, can take several weeks to complete.

What types of beer can be brewed using a 10 BBL system?

A 10 BBL brewing system is versatile and can be used to brew a wide range of beer styles, including ales, lagers, stouts, porters, and specialty brews. The system’s capacity allows for creativity and experimentation in crafting various beer recipes.

How does a 10 BBL system differ from smaller brewing setups?

Compared to smaller brewing setups, a 10 BBL system offers increased production capacity, allowing for larger batch sizes and higher output. This scalability is advantageous for commercial breweries and craft beer producers looking to expand their operations.

Was this page helpful?

Our commitment to delivering trustworthy and engaging content is at the heart of what we do. Each fact on our site is contributed by real users like you, bringing a wealth of diverse insights and information. To ensure the highest standards of accuracy and reliability, our dedicated editors meticulously review each submission. This process guarantees that the facts we share are not only fascinating but also credible. Trust in our commitment to quality and authenticity as you explore and learn with us.