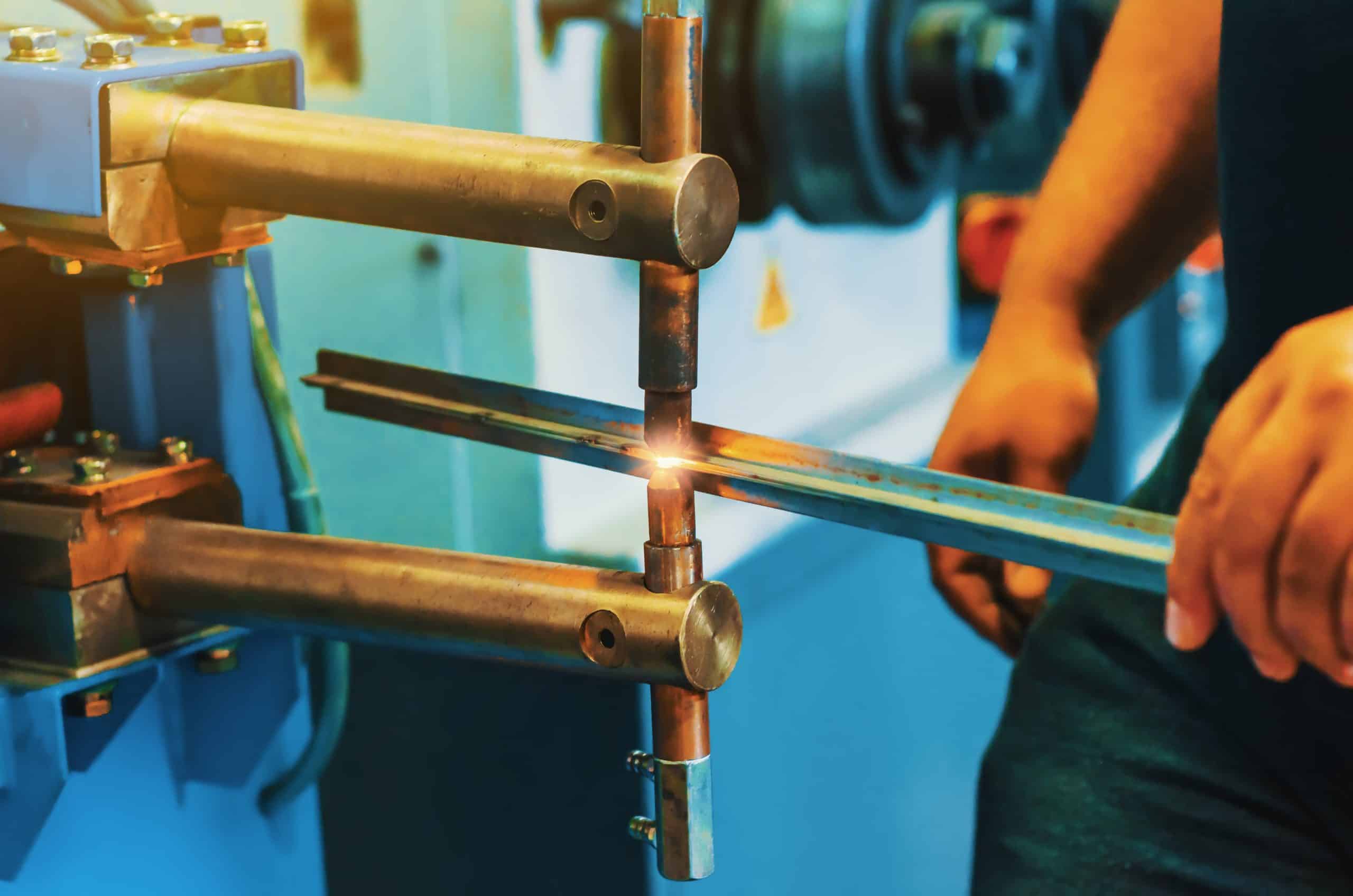

Resistance welding is a fascinating process that joins metals using heat generated from electrical resistance. But what makes it so special? This technique is widely used in various industries, from automotive to aerospace, due to its efficiency and strength. Imagine creating a strong bond without needing additional materials like solder or adhesives. How does it work? By passing a high current through metal pieces, the resistance generates heat, melting the metals at the contact point. This method is not only quick but also cost-effective. Why should you care? Understanding resistance welding can open doors to numerous applications and innovations in manufacturing. Ready to learn more? Let's dive into 38 intriguing facts about this remarkable process!

What is Resistance Welding?

Resistance welding is a process where heat is generated by passing an electric current through the resistance caused by the contact between two or more metal surfaces. This technique is widely used in various industries due to its efficiency and effectiveness. Let's dive into some fascinating facts about resistance welding.

-

Resistance welding doesn't require any filler materials, making it a clean and efficient process.

-

The process uses a combination of heat and pressure to join metals, ensuring strong and durable welds.

-

Resistance welding is commonly used in the automotive industry for assembling car bodies.

-

This welding method is ideal for mass production due to its speed and consistency.

-

The process can be automated, reducing the need for manual labor and increasing productivity.

Types of Resistance Welding

There are several types of resistance welding, each with its unique characteristics and applications. Understanding these types can help in selecting the right method for a specific project.

-

Spot Welding: This is the most common type, used for joining sheet metals by applying pressure and heat to a small area.

-

Seam Welding: Similar to spot welding, but the electrodes are wheels that roll along the seam, creating a continuous weld.

-

Projection Welding: Utilizes raised sections or projections on one of the workpieces to concentrate the welding current.

-

Flash Welding: Involves clamping two pieces together, creating an arc that heats the metal before they are pressed together.

-

Upset Welding: Similar to flash welding but without the arc; the pieces are heated by resistance and then pressed together.

Advantages of Resistance Welding

Resistance welding offers numerous benefits, making it a preferred choice in many industries. Here are some of the key advantages.

-

Efficiency: The process is quick, making it suitable for high-volume production.

-

Cost-Effective: No need for filler materials or shielding gases reduces overall costs.

-

Strong Joints: Produces strong and reliable welds, essential for structural applications.

-

Minimal Distortion: The localized heating minimizes distortion and warping of the workpieces.

-

Automation-Friendly: Easily integrated into automated systems, enhancing productivity.

Applications of Resistance Welding

Resistance welding is versatile and finds applications in various industries. Here are some common uses.

-

Automotive Industry: Used for assembling car bodies, frames, and other components.

-

Aerospace: Essential for joining lightweight materials used in aircraft construction.

-

Electronics: Utilized for making electrical connections in devices and circuits.

-

Construction: Employed in the fabrication of steel structures and frameworks.

-

Appliances: Commonly used in the manufacturing of household appliances like refrigerators and washing machines.

Safety Considerations in Resistance Welding

Safety is paramount in any welding process. Here are some important safety considerations for resistance welding.

-

Protective Gear: Always wear appropriate protective gear, including gloves, goggles, and aprons.

-

Ventilation: Ensure proper ventilation to avoid inhaling fumes and gases.

-

Electrical Safety: Be cautious of electrical hazards; ensure all equipment is properly grounded.

-

Training: Proper training is essential to operate resistance welding equipment safely.

-

Maintenance: Regular maintenance of equipment to prevent malfunctions and accidents.

Innovations in Resistance Welding

The field of resistance welding is continually evolving with new technologies and innovations. Here are some recent advancements.

-

Advanced Control Systems: Modern control systems allow for precise control of welding parameters.

-

Robotics: Integration of robotics for automated welding processes.

-

Laser-Assisted Welding: Combining resistance welding with laser technology for enhanced precision.

-

Smart Welding Machines: Machines equipped with sensors and IoT capabilities for real-time monitoring.

-

Eco-Friendly Techniques: Development of more energy-efficient and environmentally friendly welding methods.

Challenges in Resistance Welding

Despite its advantages, resistance welding also faces some challenges. Here are a few common issues.

-

Material Limitations: Not suitable for all types of materials, particularly those with high electrical resistance.

-

Thickness Restrictions: Limited to welding thin sheets; thicker materials require alternative methods.

-

Electrode Wear: Electrodes can wear out quickly, requiring frequent replacement.

-

Initial Setup Cost: High initial investment for equipment and setup.

-

Heat Affected Zone: The area around the weld can be affected by heat, potentially weakening the material.

Future of Resistance Welding

The future of resistance welding looks promising with ongoing research and development. Here are some trends to watch.

-

Automation: Increased automation for higher efficiency and consistency.

-

Material Science: Advances in material science to expand the range of weldable materials.

-

Sustainability: Focus on developing more sustainable and energy-efficient welding processes.

The Final Sparks

Resistance welding is a fascinating process that has shaped many industries. From its energy efficiency to its speed, it offers numerous advantages. Understanding the different types like spot welding, seam welding, and projection welding helps in choosing the right method for specific applications. The history of resistance welding shows its evolution and growing importance in manufacturing.

Knowing the materials that work best and the common issues helps in achieving better results. Safety measures are crucial to prevent accidents and ensure a smooth operation.

Whether you're a student, a professional, or just curious, these facts provide a solid foundation. Keep exploring and experimenting with resistance welding. The more you know, the better you can harness its potential.

Thanks for sticking around. Now, go out there and make some sparks fly!

Was this page helpful?

Our commitment to delivering trustworthy and engaging content is at the heart of what we do. Each fact on our site is contributed by real users like you, bringing a wealth of diverse insights and information. To ensure the highest standards of accuracy and reliability, our dedicated editors meticulously review each submission. This process guarantees that the facts we share are not only fascinating but also credible. Trust in our commitment to quality and authenticity as you explore and learn with us.