Finite Element Analysis (FEA) is a powerful tool used in engineering to predict how objects react to real-world forces, vibration, heat, and other physical effects. But what exactly is FEA? In simple terms, it's a computerized method for predicting how a product will react to real-world forces. Engineers use it to ensure their designs are safe, reliable, and efficient. Imagine breaking down a complex object into tiny, manageable pieces called "elements." Each element is analyzed separately, and then the results are combined to see how the entire object behaves. This method helps in designing everything from bridges and cars to smartphones and medical devices. Want to know more? Let's dive into 38 fascinating facts about FEA that will help you understand its importance and applications.

What is Finite Element Analysis (FEA)?

Finite Element Analysis (FEA) is a computerized method used to predict how a product reacts to real-world forces, vibration, heat, fluid flow, and other physical effects. Engineers and scientists use FEA to ensure their designs will perform as expected. Here are some intriguing facts about FEA.

-

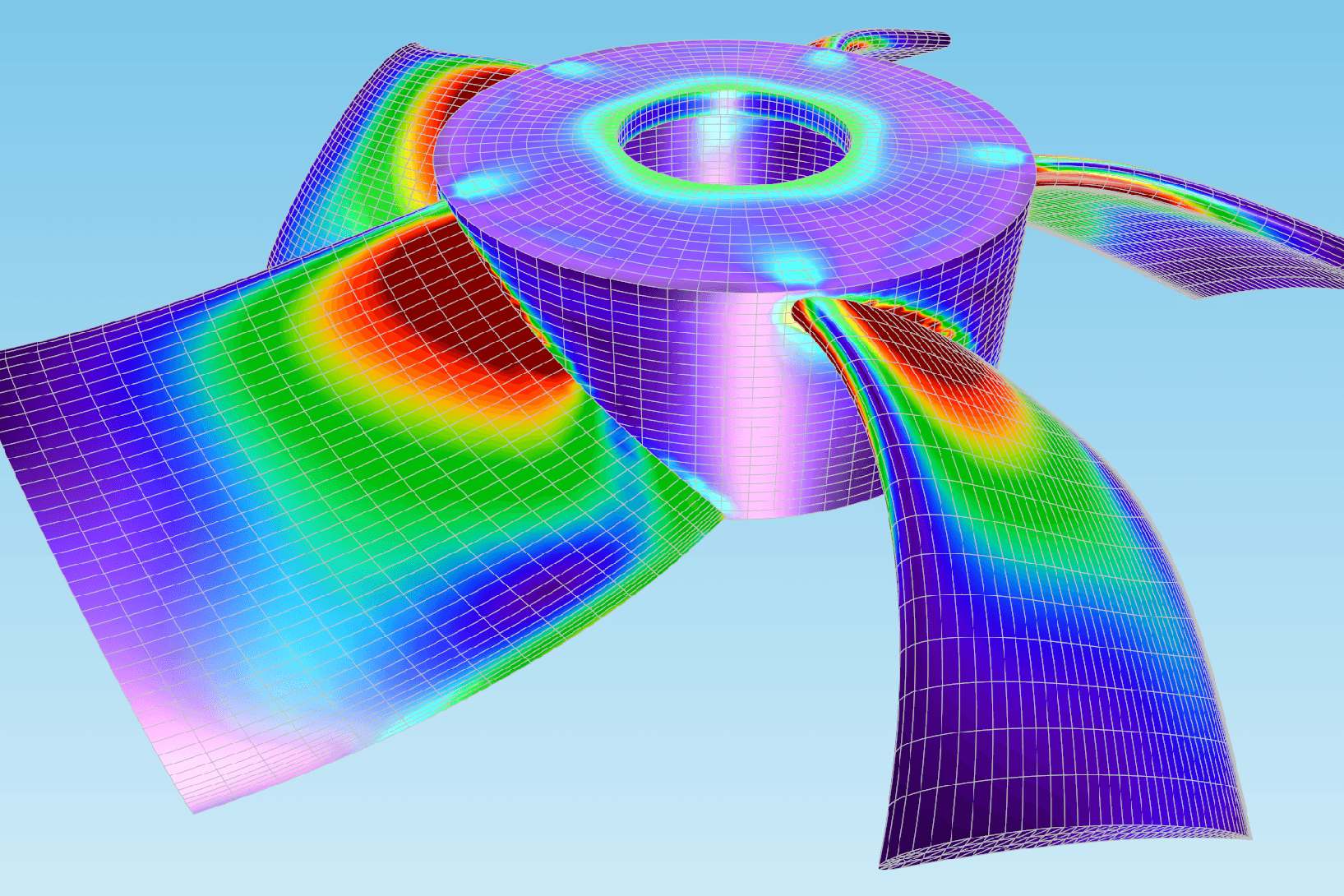

FEA divides a complex problem into smaller, simpler parts called finite elements. This makes it easier to analyze and solve.

-

The method uses mathematical equations to simulate physical phenomena. These equations are solved to predict the behavior of the system.

-

FEA can analyze both static and dynamic systems. Static analysis looks at systems in equilibrium, while dynamic analysis considers systems in motion.

-

Engineers use FEA in various industries, including aerospace, automotive, civil engineering, and biomedical fields.

-

The technique helps in optimizing designs, reducing material usage, and improving product performance.

History of FEA

Understanding the history of FEA gives insight into its development and importance in modern engineering.

-

FEA originated in the 1940s and 1950s. It was initially developed for solving complex structural problems in aerospace engineering.

-

The method became more widely used in the 1960s and 1970s with the advent of digital computers.

-

Early FEA software was developed by NASA and other research institutions. These programs laid the groundwork for modern FEA tools.

-

The first commercial FEA software, NASTRAN, was released in the late 1960s. It was developed by NASA for aerospace applications.

-

Today, numerous FEA software packages are available, including ANSYS, Abaqus, and COMSOL Multiphysics.

Applications of FEA

FEA has a wide range of applications across different fields. Here are some examples of how it is used.

-

In aerospace engineering, FEA helps design aircraft structures that can withstand extreme conditions.

-

Automotive engineers use FEA to improve vehicle safety and performance. It helps in crash simulations and optimizing fuel efficiency.

-

Civil engineers use FEA to analyze the structural integrity of buildings, bridges, and other infrastructure.

-

Biomedical engineers apply FEA to design medical devices, prosthetics, and implants. It ensures these products are safe and effective.

-

FEA is also used in electronics to analyze thermal management and structural integrity of components.

Benefits of Using FEA

The benefits of using FEA are numerous, making it an essential tool in engineering and design.

-

FEA helps in identifying potential design flaws early in the development process. This reduces the risk of costly failures.

-

The method allows for virtual testing of designs, saving time and resources compared to physical prototypes.

-

FEA provides detailed insights into the behavior of materials and structures under various conditions.

-

It helps in optimizing designs for better performance and efficiency.

-

The technique can simulate complex interactions between different physical phenomena, such as thermal and structural effects.

Challenges in FEA

Despite its advantages, FEA also has some challenges that engineers must address.

-

FEA requires significant computational resources, especially for large and complex models.

-

The accuracy of FEA results depends on the quality of the input data and the assumptions made during modeling.

-

Creating a detailed and accurate finite element model can be time-consuming and requires expertise.

-

Interpreting FEA results correctly is crucial. Misinterpretation can lead to incorrect conclusions and design decisions.

-

Engineers must validate FEA results with experimental data to ensure accuracy and reliability.

Future of FEA

The future of FEA looks promising, with advancements in technology and new applications emerging.

-

Advances in computing power and algorithms are making FEA faster and more accurate.

-

Integration with other simulation tools, such as computational fluid dynamics (CFD), is expanding the capabilities of FEA.

-

The use of artificial intelligence and machine learning in FEA is helping to automate and improve the analysis process.

-

Cloud-based FEA solutions are becoming more popular, offering scalability and accessibility.

-

FEA is being used in new fields, such as additive manufacturing and nanotechnology.

Interesting Facts About FEA

Here are some additional interesting facts about FEA that highlight its versatility and impact.

-

FEA can simulate the behavior of materials at different scales, from macroscopic structures to microscopic components.

-

The method is used in the entertainment industry to create realistic animations and special effects.

-

FEA helps in the design of sports equipment, such as helmets, golf clubs, and running shoes.

-

The technique is used in the energy sector to analyze the performance of wind turbines, solar panels, and other renewable energy systems.

-

FEA can simulate the effects of aging and wear on materials and structures, helping to predict their lifespan.

-

The method is used in the design of consumer products, such as smartphones and household appliances, to ensure durability and performance.

-

FEA is an essential tool in the development of new materials, such as composites and advanced alloys.

-

The technique is used in the study of natural phenomena, such as earthquakes and tsunamis, to improve disaster preparedness and response.

The Power of Finite Element Analysis

Finite Element Analysis (FEA) is a game-changer in engineering and design. It helps predict how products will react to real-world forces, reducing the need for physical prototypes. This saves time and money while increasing safety and efficiency. From aerospace to automotive industries, FEA is crucial for innovation.

Understanding FEA's basics, like meshing and boundary conditions, can open doors to advanced simulations. Engineers can test materials, optimize designs, and ensure compliance with standards. This leads to better-performing, more reliable products.

FEA isn't just for experts. With user-friendly software, even beginners can start exploring its benefits. As technology advances, FEA will become even more accessible and powerful.

So, whether you're an engineer, designer, or just curious, FEA offers valuable insights. Embrace this tool to stay ahead in a competitive world.

Was this page helpful?

Our commitment to delivering trustworthy and engaging content is at the heart of what we do. Each fact on our site is contributed by real users like you, bringing a wealth of diverse insights and information. To ensure the highest standards of accuracy and reliability, our dedicated editors meticulously review each submission. This process guarantees that the facts we share are not only fascinating but also credible. Trust in our commitment to quality and authenticity as you explore and learn with us.