Sheet metal design is a fascinating field that combines creativity, engineering, and precision. Did you know that sheet metal can be as thin as 0.5 mm or as thick as 6 mm? This versatility makes it perfect for everything from car bodies to intricate electronic enclosures. One cool fact is that sheet metal can be bent, cut, and shaped into almost any form, thanks to techniques like laser cutting and CNC machining. Another interesting point is that aluminum, steel, and copper are the most commonly used materials in sheet metal design. Want to know more? Keep reading to uncover 36 amazing facts about this incredible material!

What is Sheet Metal Design?

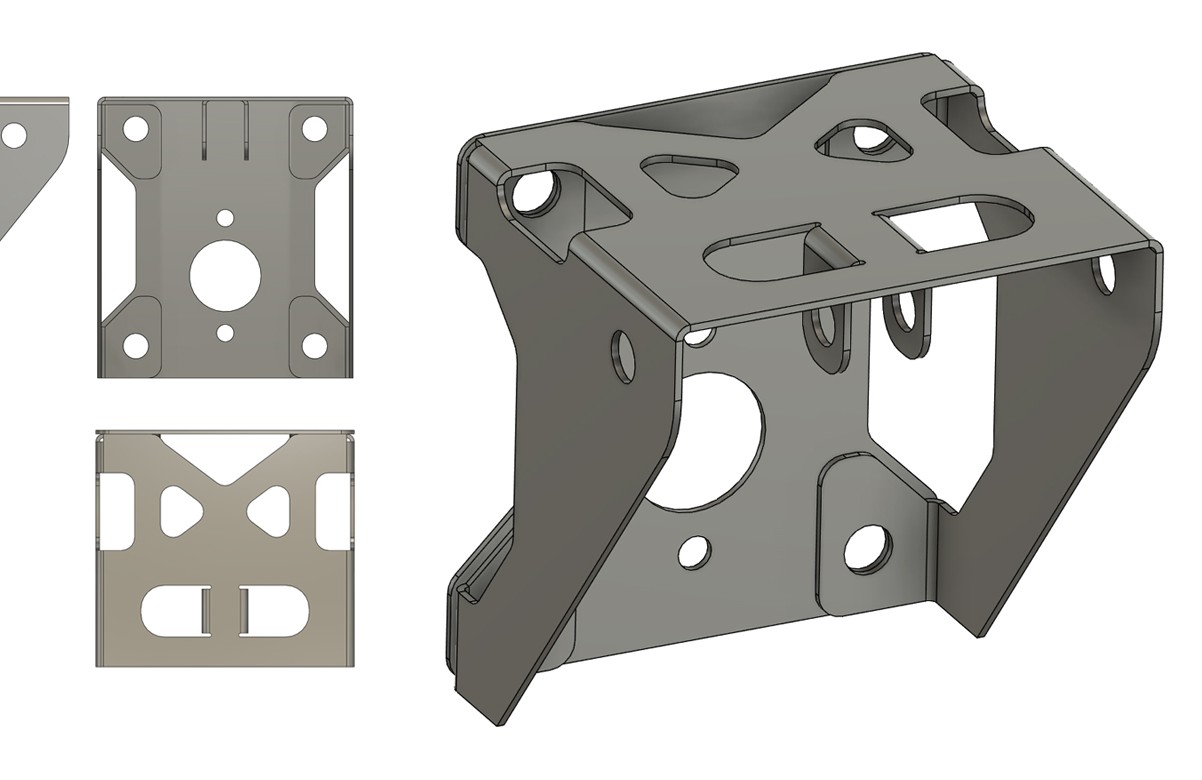

Sheet metal design involves creating parts and products from thin metal sheets. This process is essential in various industries, including automotive, aerospace, and construction. Let's dive into some fascinating facts about sheet metal design.

The Basics of Sheet Metal

Understanding the fundamentals of sheet metal is crucial for anyone interested in this field.

- Sheet Metal Thickness: Sheet metal thickness is measured in gauges. The higher the gauge number, the thinner the metal. For example, 18-gauge steel is thicker than 22-gauge steel.

- Common Materials: Common materials used in sheet metal design include steel, aluminum, copper, and brass. Each material has unique properties that make it suitable for different applications.

- Sheet Metal Uses: Sheet metal is used in various applications, from car bodies to HVAC systems, due to its versatility and durability.

Techniques in Sheet Metal Design

Several techniques are employed to shape and form sheet metal into the desired design.

- Cutting: Cutting is the first step in sheet metal design. Methods include laser cutting, plasma cutting, and waterjet cutting, each offering different levels of precision and speed.

- Bending: Bending involves deforming the metal along a straight line. This is typically done using a press brake, which can create precise bends.

- Stamping: Stamping uses a die to cut or shape the metal. This technique is often used for mass production of parts.

- Punching: Punching creates holes in the metal using a punch press. This method is efficient for creating multiple holes quickly.

- Forming: Forming involves shaping the metal without removing any material. Techniques include rolling, spinning, and deep drawing.

Advanced Sheet Metal Design Processes

Advanced processes enhance the capabilities of sheet metal design, allowing for more complex and precise creations.

- CNC Machining: CNC (Computer Numerical Control) machining uses computer programs to control machine tools, enabling highly accurate and repeatable designs.

- Laser Cutting: Laser cutting uses a focused laser beam to cut materials with high precision. This method is ideal for intricate designs.

- Waterjet Cutting: Waterjet cutting uses a high-pressure stream of water mixed with abrasive particles to cut through metal. It is suitable for materials that cannot withstand high temperatures.

- Plasma Cutting: Plasma cutting uses an electrically conductive gas to cut through metal. It is faster than other cutting methods but less precise.

Design Considerations in Sheet Metal

Designing with sheet metal requires careful consideration of various factors to ensure functionality and manufacturability.

- Material Selection: Choosing the right material is crucial. Factors to consider include strength, weight, corrosion resistance, and cost.

- Bend Radius: The bend radius should be considered to prevent cracking or deforming the metal. A larger bend radius reduces the risk of damage.

- Tolerance: Tolerance refers to the allowable variation in dimensions. Tight tolerances ensure parts fit together correctly but can increase manufacturing costs.

- K-Factor: The K-factor is a constant used in bending calculations to account for material stretching. It helps in predicting the final dimensions of a bent part.

- Grain Direction: The grain direction of the metal affects its bending properties. Bending perpendicular to the grain can cause cracking.

Applications of Sheet Metal Design

Sheet metal design plays a vital role in various industries, contributing to the creation of numerous products.

- Automotive Industry: Sheet metal is used to manufacture car bodies, chassis, and other components due to its strength and formability.

- Aerospace Industry: Lightweight and strong, sheet metal is ideal for aircraft components, including fuselages and wings.

- Construction Industry: Sheet metal is used in roofing, siding, and structural components, offering durability and weather resistance.

- HVAC Systems: Heating, ventilation, and air conditioning systems rely on sheet metal for ducts and other components.

- Consumer Electronics: Sheet metal is used in the casings of electronic devices, providing protection and structural integrity.

Innovations in Sheet Metal Design

The field of sheet metal design continually evolves, with new technologies and methods enhancing its capabilities.

- 3D Printing: 3D printing with metal allows for the creation of complex, custom parts that would be difficult or impossible to produce with traditional methods.

- Robotic Automation: Robots are increasingly used in sheet metal fabrication, improving precision and efficiency while reducing labor costs.

- Smart Manufacturing: Smart manufacturing integrates advanced technologies like IoT and AI to optimize production processes and improve quality control.

- Sustainable Practices: Sustainable practices in sheet metal design include recycling scrap metal and using eco-friendly materials and processes.

Challenges in Sheet Metal Design

Despite its many advantages, sheet metal design also presents several challenges that must be addressed.

- Material Waste: Minimizing material waste is a significant challenge, as cutting and forming processes can produce scrap metal.

- Complex Geometries: Creating complex geometries can be difficult and may require advanced techniques and equipment.

- Cost Management: Balancing cost with quality and functionality is crucial, as high-quality materials and precise processes can be expensive.

- Thermal Effects: Processes like welding and cutting can introduce thermal effects that alter the properties of the metal, potentially leading to warping or weakening.

- Surface Finish: Achieving a high-quality surface finish can be challenging, especially for parts that require additional treatments like painting or coating.

Future Trends in Sheet Metal Design

The future of sheet metal design looks promising, with several trends shaping its development.

- Increased Automation: Automation will continue to play a significant role, with more advanced robots and AI systems improving efficiency and precision.

- Advanced Materials: New materials with enhanced properties, such as increased strength and corrosion resistance, will expand the possibilities of sheet metal design.

- Customization: The demand for customized products will drive the development of flexible manufacturing processes that can produce small batches efficiently.

- Sustainability: Sustainability will become increasingly important, with a focus on reducing waste, recycling materials, and using eco-friendly processes.

- Integration with Digital Technologies: The integration of digital technologies, such as CAD software and IoT, will streamline the design and manufacturing process, improving accuracy and reducing lead times.

The Final Cut

Sheet metal design is more than just bending and cutting metal. It involves a mix of engineering, creativity, and precision. From automobiles to airplanes, electronics to architecture, sheet metal plays a crucial role in our daily lives. Knowing these 36 facts can give you a better appreciation for the craft and its impact on various industries.

Whether you're a student, a professional, or just curious, understanding the basics of sheet metal design can open up new perspectives. It’s a field that combines art and science, requiring both technical skills and innovative thinking. So next time you see a sleek car or a sturdy bridge, remember the intricate sheet metal work behind it.

Keep exploring, keep learning, and who knows? You might find yourself inspired to dive deeper into the world of sheet metal design.

Was this page helpful?

Our commitment to delivering trustworthy and engaging content is at the heart of what we do. Each fact on our site is contributed by real users like you, bringing a wealth of diverse insights and information. To ensure the highest standards of accuracy and reliability, our dedicated editors meticulously review each submission. This process guarantees that the facts we share are not only fascinating but also credible. Trust in our commitment to quality and authenticity as you explore and learn with us.