Fatigue analysis is a crucial process in engineering that helps predict the lifespan of materials under repeated stress. But what exactly is fatigue analysis? In simple terms, it's a method used to determine how long a material can withstand cyclic loading before it fails. This technique is vital for ensuring the safety and durability of structures like bridges, airplanes, and even everyday items like car parts. Engineers use it to identify potential weak points and improve designs, making our world safer. Understanding fatigue analysis can help you appreciate the science behind the structures we often take for granted. Ready to learn some intriguing facts? Let's dive in!

What is Fatigue Analysis?

Fatigue analysis is a method used to predict the life of a material or structure under repeated loading and unloading. This process helps engineers and designers ensure safety and durability. Let's dive into some fascinating facts about fatigue analysis.

-

Fatigue analysis is crucial in industries like aerospace, automotive, and civil engineering to prevent catastrophic failures.

-

The term "fatigue" was first used in the 19th century to describe the weakening of materials under cyclic loading.

-

Fatigue failure occurs when a material cracks and eventually breaks after being subjected to repeated stress cycles.

The Science Behind Fatigue Analysis

Understanding the science behind fatigue analysis involves looking at how materials respond to stress over time. Here are some key points:

-

Fatigue life is the number of stress cycles a material can withstand before failure.

-

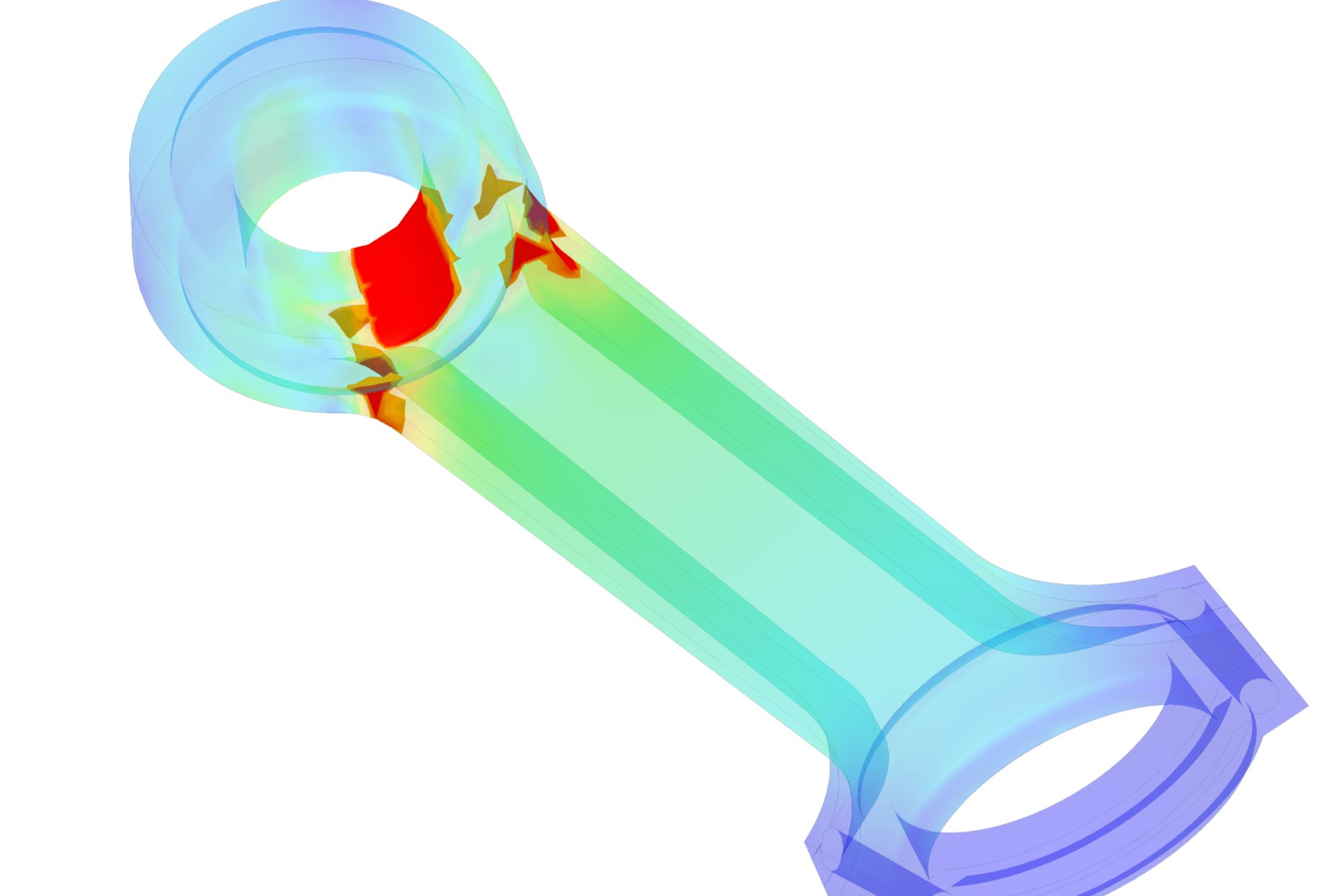

Stress concentration areas, such as notches or holes, are more susceptible to fatigue failure.

-

The S-N curve, or Wöhler curve, represents the relationship between stress (S) and the number of cycles to failure (N).

Factors Affecting Fatigue Life

Several factors can influence the fatigue life of a material. Knowing these can help in designing more durable structures.

-

Surface finish plays a significant role; rough surfaces can reduce fatigue life.

-

Environmental conditions, like temperature and humidity, can accelerate fatigue failure.

-

Material properties, such as hardness and ductility, affect how well a material can resist fatigue.

Methods of Fatigue Testing

Various methods are used to test materials for fatigue. Each method provides insights into how a material will perform under cyclic loading.

-

Rotating bending tests involve rotating a specimen while applying a bending load.

-

Axial loading tests apply a direct tensile or compressive load along the axis of the specimen.

-

Torsional fatigue tests twist the specimen to simulate real-world conditions.

Applications of Fatigue Analysis

Fatigue analysis is applied in numerous fields to ensure the longevity and safety of components and structures.

-

In the aerospace industry, fatigue analysis helps in designing aircraft components that can withstand repeated stress during flights.

-

Automotive engineers use fatigue analysis to improve the durability of car parts like suspension systems and engine components.

-

Civil engineers apply fatigue analysis to design bridges and buildings that can endure environmental stressors over time.

Advanced Techniques in Fatigue Analysis

With technological advancements, new techniques have emerged to enhance fatigue analysis.

-

Finite Element Analysis (FEA) allows for detailed simulations of how materials will respond to stress.

-

Fracture mechanics helps in understanding how cracks initiate and propagate in materials.

-

Acoustic emission testing detects the sound waves produced by crack formation, providing early warning signs of fatigue failure.

Real-World Examples of Fatigue Failure

Learning from past failures can help prevent future ones. Here are some notable examples:

-

The De Havilland Comet, the world's first commercial jetliner, suffered catastrophic fatigue failures in the 1950s due to metal fatigue.

-

The Silver Bridge collapse in 1967 was caused by a single eyebar failing due to fatigue, leading to the deaths of 46 people.

-

The Aloha Airlines Flight 243 incident in 1988 involved a section of the fuselage tearing away mid-flight due to fatigue cracks.

Preventing Fatigue Failure

Preventing fatigue failure involves a combination of good design practices and regular maintenance.

-

Regular inspections can help detect early signs of fatigue, allowing for timely repairs.

-

Using materials with higher fatigue strength can extend the life of components.

-

Implementing design changes, such as adding fillets to reduce stress concentrations, can improve fatigue resistance.

Future of Fatigue Analysis

The future of fatigue analysis looks promising with ongoing research and technological advancements.

-

Machine learning algorithms are being developed to predict fatigue life more accurately.

-

Nanotechnology is being explored to create materials with superior fatigue resistance.

-

3D printing allows for the creation of complex geometries that can distribute stress more evenly, reducing fatigue risk.

Interesting Facts About Fatigue Analysis

Here are some additional intriguing facts about fatigue analysis that you might find surprising.

-

Fatigue cracks can grow even under very low stress levels, making them difficult to detect early.

-

The Paris Law describes the rate of crack growth per cycle as a function of the stress intensity factor.

-

Shot peening, a process that bombards the surface of a material with small spherical media, can improve fatigue life by inducing compressive residual stresses.

Common Misconceptions About Fatigue Analysis

There are several misconceptions about fatigue analysis that need clarification.

-

Fatigue failure is not always due to high stress; even low stress can cause failure if applied repeatedly.

-

Fatigue life is not solely determined by the material; design and environmental factors also play a crucial role.

-

A material that performs well in static tests may still fail under cyclic loading due to fatigue.

The Role of Standards in Fatigue Analysis

Standards ensure consistency and reliability in fatigue analysis across different industries.

-

ASTM International provides standardized methods for fatigue testing, ensuring uniformity in results.

-

The International Organization for Standardization (ISO) also has guidelines for fatigue testing and analysis.

-

Adhering to these standards helps in comparing results and improving the overall reliability of fatigue analysis.

The Bottom Line on Fatigue

Fatigue isn’t just about feeling tired. It’s a complex issue affecting both body and mind. From sleep disorders to chronic illnesses, many factors can contribute. Understanding these can help in managing and reducing fatigue. Simple lifestyle changes like improving sleep hygiene, staying hydrated, and regular exercise can make a big difference. Don’t ignore persistent fatigue; it might be a sign of something more serious. Consult a healthcare professional if you’re constantly feeling drained. Knowledge is power, and being informed about the causes and remedies can lead to a more energetic life. Stay proactive, listen to your body, and take steps to combat fatigue. It’s not just about getting more sleep; it’s about a holistic approach to health.

Was this page helpful?

Our commitment to delivering trustworthy and engaging content is at the heart of what we do. Each fact on our site is contributed by real users like you, bringing a wealth of diverse insights and information. To ensure the highest standards of accuracy and reliability, our dedicated editors meticulously review each submission. This process guarantees that the facts we share are not only fascinating but also credible. Trust in our commitment to quality and authenticity as you explore and learn with us.