Ultrasonic welding might sound like something out of a sci-fi movie, but it's a real and fascinating technology used in various industries. What is ultrasonic welding? It's a process that uses high-frequency sound waves to join materials, usually plastics or metals, without needing adhesives, screws, or heat from an external source. This technique is quick, efficient, and creates strong bonds. Imagine putting together car parts, electronics, or even medical devices with sound! Ultrasonic welding is not only fast but also environmentally friendly since it doesn't produce harmful fumes or waste. Ready to learn more? Let's dive into 35 intriguing facts about this cutting-edge technology!

What is Ultrasonic Welding?

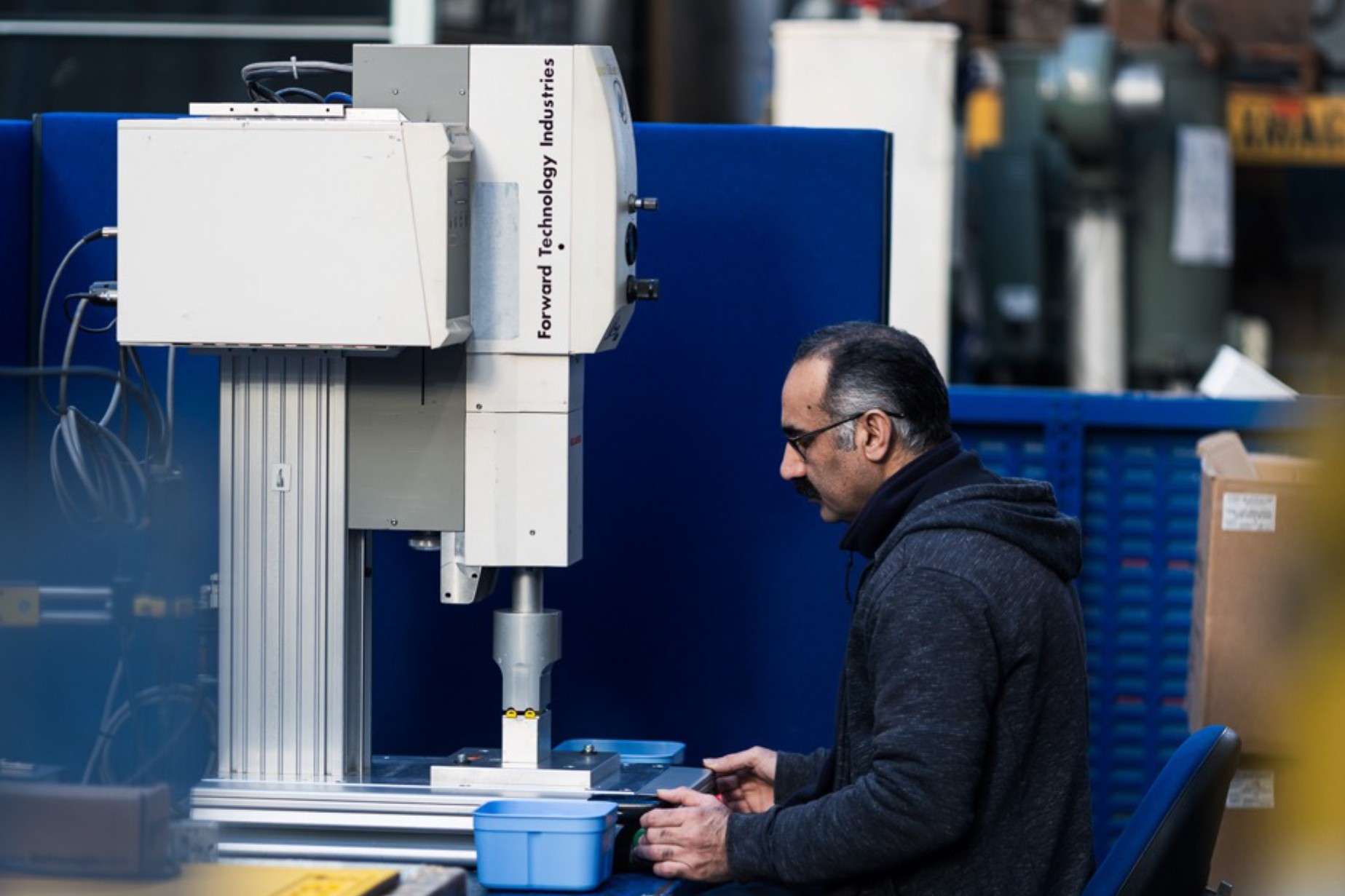

Ultrasonic welding is a technique that uses high-frequency ultrasonic vibrations to join materials, typically plastics or metals. This method is widely used in various industries due to its efficiency and precision. Let's dive into some fascinating facts about ultrasonic welding.

-

Invented in the 1960s

Ultrasonic welding was first developed in the 1960s. This innovation revolutionized manufacturing processes, especially in the automotive and electronics industries. -

No Need for Adhesives

Unlike traditional welding, ultrasonic welding doesn't require adhesives or solvents. The process relies solely on ultrasonic vibrations to create a strong bond. -

Works at Low Temperatures

The technique operates at relatively low temperatures compared to conventional welding. This reduces the risk of thermal damage to the materials being joined. -

Used in Medical Devices

Ultrasonic welding is commonly used to manufacture medical devices. Its precision and cleanliness make it ideal for producing items like catheters and surgical instruments.

How Ultrasonic Welding Works

Understanding the mechanics behind ultrasonic welding can be quite intriguing. Here are some key points about how this technology functions.

-

High-Frequency Vibrations

The process uses high-frequency vibrations, typically in the range of 20 kHz to 40 kHz. These vibrations generate heat through friction, which melts the materials and fuses them together. -

Transducer and Horn

A transducer converts electrical energy into mechanical vibrations. These vibrations are then transmitted through a horn, which focuses the energy onto the materials being welded. -

Pressure Application

Pressure is applied to the materials during the welding process. This helps to ensure a strong bond as the materials cool and solidify. -

Short Welding Time

The entire welding process usually takes just a few seconds. This makes ultrasonic welding incredibly efficient for mass production.

Applications of Ultrasonic Welding

Ultrasonic welding has a wide range of applications across various industries. Here are some examples of where this technology is used.

-

Automotive Industry

In the automotive sector, ultrasonic welding is used to join plastic components, such as dashboards and door panels. It ensures a strong, durable bond without the need for additional adhesives. -

Electronics Manufacturing

This technique is essential in electronics manufacturing. It is used to assemble circuit boards, connect wires, and even seal battery cases. -

Packaging Industry

Ultrasonic welding is employed in the packaging industry to seal containers and packages. It provides a tamper-proof seal, ensuring product safety. -

Textile Industry

In textiles, ultrasonic welding is used to create seams and hems without stitching. This method is faster and more efficient than traditional sewing.

Advantages of Ultrasonic Welding

Ultrasonic welding offers numerous benefits that make it a preferred choice in many industries. Here are some of its key advantages.

-

Energy Efficiency

The process is highly energy-efficient. It uses less power compared to traditional welding methods, making it more environmentally friendly. -

Strong Bonds

Ultrasonic welding creates strong, reliable bonds. The joints are often as strong as or stronger than the original materials. -

Clean Process

The technique is clean and doesn't produce fumes or residues. This makes it suitable for applications where cleanliness is crucial, such as in medical device manufacturing. -

No Consumables Needed

Unlike other welding methods, ultrasonic welding doesn't require consumables like solder or adhesives. This reduces material costs and simplifies the process.

Challenges in Ultrasonic Welding

Despite its many advantages, ultrasonic welding does come with some challenges. Here are a few issues that manufacturers might face.

-

Material Compatibility

Not all materials are suitable for ultrasonic welding. The technique works best with thermoplastics and some metals, but other materials may not bond effectively. -

Initial Setup Cost

The initial cost of ultrasonic welding equipment can be high. However, the long-term savings in materials and efficiency often outweigh the initial investment. -

Thickness Limitations

The process is most effective for materials of certain thicknesses. Very thick or very thin materials may not weld properly. -

Skill Requirement

Operators need specialized training to use ultrasonic welding equipment effectively. This can add to the overall cost and complexity of the process.

Innovations in Ultrasonic Welding

The field of ultrasonic welding is continually evolving. Here are some recent innovations that are pushing the boundaries of this technology.

-

Automated Systems

Advances in automation have led to the development of fully automated ultrasonic welding systems. These systems increase efficiency and reduce the need for manual intervention. -

Advanced Materials

New materials are being developed that are more compatible with ultrasonic welding. These materials expand the range of applications for this technology. -

Improved Horn Designs

Innovations in horn design have improved the efficiency and effectiveness of ultrasonic welding. These new designs focus energy more precisely, resulting in stronger bonds. -

Real-Time Monitoring

Modern ultrasonic welding systems often include real-time monitoring capabilities. This allows operators to track the welding process and make adjustments as needed.

Environmental Impact of Ultrasonic Welding

Ultrasonic welding is considered an environmentally friendly technology. Here are some reasons why it has a positive impact on the environment.

-

Reduced Waste

The process generates very little waste. There are no adhesives or solvents to dispose of, and the materials used are often recyclable. -

Lower Energy Consumption

Ultrasonic welding uses less energy compared to traditional welding methods. This reduces the overall carbon footprint of the manufacturing process. -

No Emissions

The technique doesn't produce harmful emissions or fumes. This makes it a safer option for both workers and the environment. -

Recyclable Materials

Many of the materials used in ultrasonic welding are recyclable. This further reduces the environmental impact of the process.

Future of Ultrasonic Welding

The future of ultrasonic welding looks promising. Here are some trends and developments that could shape the future of this technology.

-

Increased Automation

The trend towards automation is likely to continue. More industries will adopt automated ultrasonic welding systems to improve efficiency and reduce labor costs. -

New Applications

As the technology advances, new applications for ultrasonic welding will emerge. This could include areas like aerospace, renewable energy, and more. -

Enhanced Precision

Future developments will likely focus on improving the precision of ultrasonic welding. This will make it suitable for even more demanding applications. -

Integration with AI

Artificial intelligence could play a significant role in the future of ultrasonic welding. AI algorithms could optimize the welding process, making it more efficient and reliable.

Interesting Facts About Ultrasonic Welding

Here are some additional interesting facts that highlight the versatility and uniqueness of ultrasonic welding.

-

Used in Toy Manufacturing

Ultrasonic welding is used to assemble plastic toys. It ensures that the toys are durable and safe for children. -

NASA Uses It

NASA employs ultrasonic welding in the construction of spacecraft components. The technique provides the strength and reliability needed for space missions. -

Jewelry Making

Some jewelers use ultrasonic welding to create intricate designs. The precision of the technique allows for the creation of delicate and detailed pieces.

Ultrasonic Welding: A Game Changer

Ultrasonic welding has revolutionized manufacturing. This technique uses high-frequency sound waves to join materials, making it efficient and precise. It's widely used in industries like automotive, electronics, and medical devices. The process is fast, clean, and doesn't require adhesives or solvents, which makes it environmentally friendly.

Understanding the basics of ultrasonic welding can help you appreciate its impact on modern production. From creating durable plastic parts to ensuring the integrity of electronic components, this method is a cornerstone of innovation.

As technology advances, ultrasonic welding will likely become even more integral to various industries. Its ability to create strong, reliable bonds quickly and cleanly sets it apart from traditional methods. So, next time you use a product, remember that ultrasonic welding might have played a crucial role in its creation.

Was this page helpful?

Our commitment to delivering trustworthy and engaging content is at the heart of what we do. Each fact on our site is contributed by real users like you, bringing a wealth of diverse insights and information. To ensure the highest standards of accuracy and reliability, our dedicated editors meticulously review each submission. This process guarantees that the facts we share are not only fascinating but also credible. Trust in our commitment to quality and authenticity as you explore and learn with us.