Physical vapor deposition (PVD) might sound like a complex term, but it's a fascinating process used to coat materials with thin films. PVD involves transforming solid materials into vapor, which then deposits onto a target surface, creating a thin, durable layer. This technique is widely used in industries like electronics, aerospace, and even jewelry. Ever wondered how your smartphone gets its sleek, scratch-resistant surface? That's PVD at work! From improving wear resistance to enhancing aesthetic appeal, PVD plays a crucial role in modern manufacturing. Ready to dive into 35 intriguing facts about this amazing technology? Let's get started!

What is Physical Vapor Deposition (PVD)?

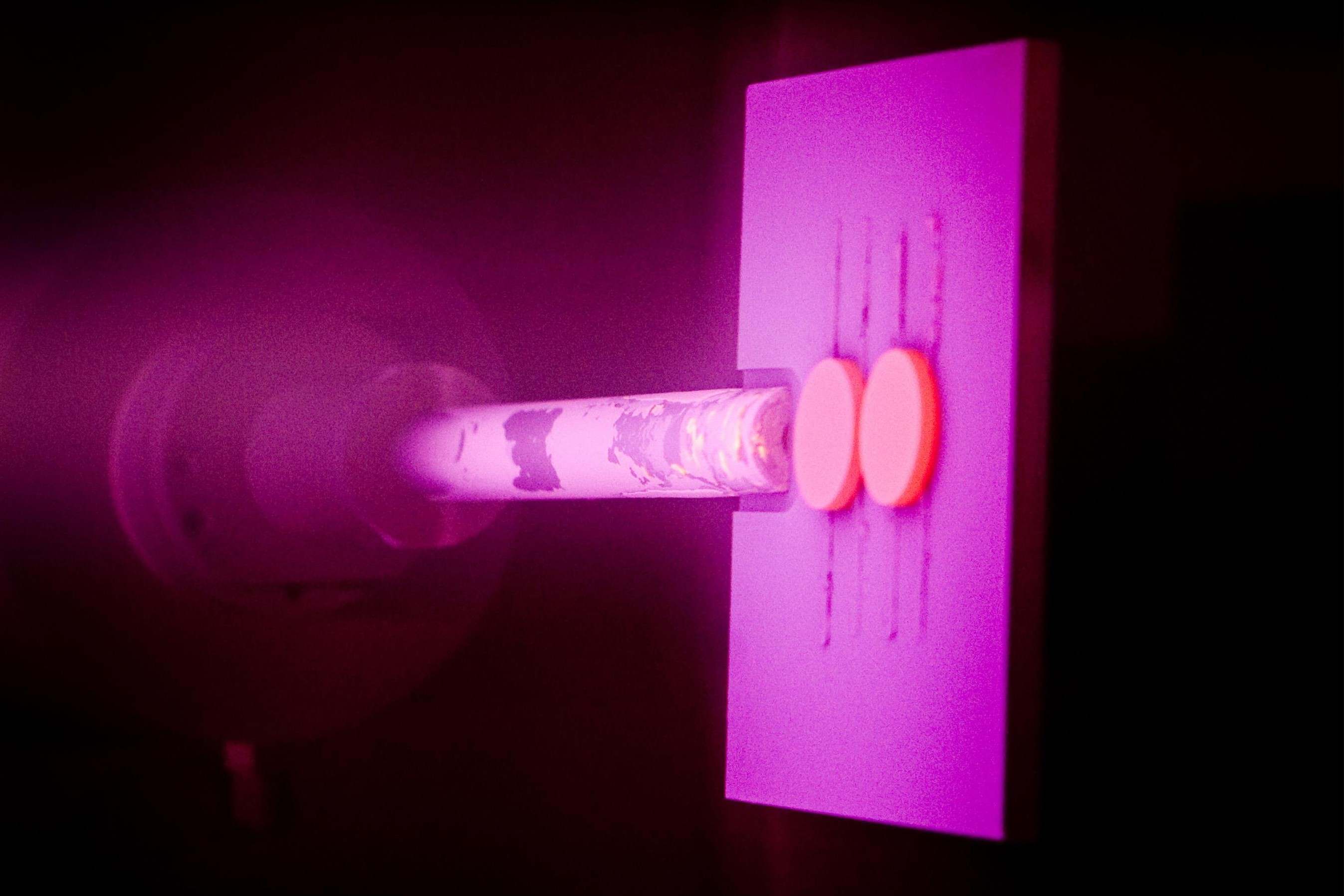

Physical Vapor Deposition (PVD) is a process used to create thin films and coatings. This technique involves vaporizing a solid material in a vacuum and depositing it onto a substrate. PVD is widely used in various industries, including electronics, optics, and manufacturing. Let's dive into some fascinating facts about PVD.

-

PVD is a vacuum coating process that involves three main steps: vaporization, transportation, and condensation.

-

The process can be used to deposit a wide range of materials, including metals, alloys, and ceramics.

-

PVD coatings are known for their high hardness and wear resistance, making them ideal for cutting tools and industrial machinery.

-

The technique is environmentally friendly because it produces minimal waste compared to other coating methods.

-

PVD can be used to create decorative finishes on consumer products like watches, jewelry, and automotive parts.

How Does PVD Work?

Understanding the mechanics behind PVD can help appreciate its applications and benefits. Here are some key points about how PVD works.

-

The process begins with the evaporation of the coating material in a high-vacuum environment.

-

The vaporized material then travels through the vacuum chamber and condenses on the substrate, forming a thin film.

-

PVD can be performed using various methods, including sputtering, evaporation, and arc vapor deposition.

-

Sputtering involves bombarding a target material with high-energy particles to release atoms that then deposit on the substrate.

-

Evaporation uses heat to vaporize the coating material, which then condenses on the substrate.

Applications of PVD

PVD has a wide range of applications across different industries. Here are some interesting facts about where and how PVD is used.

-

In the electronics industry, PVD is used to create thin films for semiconductors and integrated circuits.

-

The optics industry uses PVD to produce anti-reflective coatings on lenses and mirrors.

-

PVD coatings are applied to cutting tools to extend their lifespan and improve performance.

-

The automotive industry uses PVD for decorative and functional coatings on various components.

-

Medical devices, such as implants and surgical instruments, benefit from PVD coatings due to their biocompatibility and durability.

Advantages of PVD

PVD offers several advantages over other coating methods. Here are some compelling reasons why PVD is a preferred choice.

-

PVD coatings are highly durable and resistant to wear, corrosion, and oxidation.

-

The process allows for precise control over the thickness and composition of the coating.

-

PVD can be used to coat complex shapes and geometries, making it versatile for various applications.

-

The coatings produced by PVD are typically very smooth and have a high-quality finish.

-

PVD is a dry process, which means it does not require the use of hazardous chemicals or solvents.

Challenges and Limitations of PVD

Despite its many advantages, PVD also has some challenges and limitations. Here are a few to consider.

-

The initial setup cost for PVD equipment can be high, making it less accessible for small-scale operations.

-

The process requires a high-vacuum environment, which can be complex and expensive to maintain.

-

PVD coatings may not adhere well to certain substrates, requiring additional surface preparation.

-

The process can be time-consuming, especially for large-scale production runs.

-

PVD is not suitable for coating materials with low melting points, as they may not withstand the high temperatures involved.

Innovations in PVD Technology

PVD technology continues to evolve, with new innovations enhancing its capabilities and applications. Here are some recent developments in the field.

-

Advances in PVD equipment have led to faster deposition rates and improved coating uniformity.

-

New materials are being developed for PVD coatings, offering enhanced properties such as higher hardness and better corrosion resistance.

-

Hybrid PVD processes, which combine PVD with other coating techniques, are being explored to achieve better performance.

-

Researchers are investigating the use of PVD for creating nanostructured coatings with unique properties.

-

The development of more efficient vacuum systems has reduced the energy consumption of PVD processes.

Environmental Impact of PVD

PVD is considered an environmentally friendly coating method. Here are some facts about its environmental impact.

-

PVD produces minimal waste and does not generate hazardous by-products.

-

The process does not require the use of toxic chemicals or solvents, reducing the risk of environmental contamination.

-

PVD coatings can extend the lifespan of products, reducing the need for frequent replacements and conserving resources.

-

The energy efficiency of modern PVD equipment has improved, reducing the overall carbon footprint of the process.

-

PVD can be used to create coatings that improve the energy efficiency of products, such as low-emissivity coatings for windows.

The Final Word on Physical Vapor Deposition

Physical vapor deposition (PVD) is a fascinating process with many applications. From creating durable coatings on tools to producing thin films for electronics, PVD is everywhere. It’s a cleaner, more efficient alternative to traditional methods, making it a go-to for industries focused on sustainability. The process involves vaporizing a solid material and depositing it onto a substrate, resulting in a thin, high-quality coating.

PVD’s versatility makes it invaluable in fields like aerospace, automotive, and even jewelry. Its ability to produce hard, wear-resistant surfaces means longer-lasting products. Plus, the range of materials that can be used in PVD allows for endless possibilities in innovation.

Understanding PVD gives insight into how many everyday items are made more durable and efficient. This technology continues to evolve, promising even more exciting developments in the future.

Was this page helpful?

Our commitment to delivering trustworthy and engaging content is at the heart of what we do. Each fact on our site is contributed by real users like you, bringing a wealth of diverse insights and information. To ensure the highest standards of accuracy and reliability, our dedicated editors meticulously review each submission. This process guarantees that the facts we share are not only fascinating but also credible. Trust in our commitment to quality and authenticity as you explore and learn with us.