Electron beam welding (EBW) is a high-precision welding process that uses a focused beam of electrons to join materials. But what makes EBW so special? First, it can weld a wide range of metals, including those that are difficult to weld using traditional methods. Second, it offers deep penetration with minimal distortion, making it ideal for intricate and high-strength applications. Third, EBW operates in a vacuum, which eliminates contamination and oxidation, ensuring a clean weld. Finally, this method is highly efficient, reducing the need for additional processing. Curious about more? Let's dive into 32 fascinating facts about this cutting-edge technology!

What is Electron Beam Welding?

Electron beam welding (EBW) is a fusion welding process where a beam of high-velocity electrons is applied to materials to join them. This technique is known for its precision and ability to weld thick materials with minimal distortion.

-

Invented in 1958: EBW was developed by German physicist Karl-Heinz Steigerwald. His invention revolutionized welding in aerospace and other high-tech industries.

-

Works in a Vacuum: EBW typically occurs in a vacuum chamber to prevent electron scattering by air molecules. This ensures a focused and powerful beam.

-

High Energy Density: The electron beam can reach energy densities up to 10^7 W/cm², allowing it to weld thick sections quickly and efficiently.

-

Minimal Heat-Affected Zone: Due to its precision, EBW produces a very small heat-affected zone, reducing the risk of material distortion and weakening.

Applications of Electron Beam Welding

EBW is used in various industries due to its precision and efficiency. Here are some notable applications:

-

Aerospace Industry: EBW is crucial for manufacturing aircraft engines and structural components, ensuring strong and reliable joints.

-

Automotive Industry: Used for welding gear parts, turbochargers, and fuel injectors, EBW helps in producing high-performance automotive components.

-

Medical Devices: Precision is vital in medical device manufacturing. EBW is used to weld components like pacemakers and surgical instruments.

-

Electronics: EBW is employed in the production of microelectronics, where tiny, precise welds are necessary.

-

Nuclear Industry: The ability to weld thick sections with minimal defects makes EBW ideal for nuclear reactor components.

Advantages of Electron Beam Welding

EBW offers several benefits over traditional welding methods. Here are some key advantages:

-

High Precision: EBW can produce extremely precise welds, making it ideal for intricate and delicate components.

-

Deep Penetration: The high energy density allows for deep penetration welds, which is beneficial for thick materials.

-

Low Distortion: The minimal heat-affected zone results in low thermal distortion, preserving the integrity of the materials.

-

Clean Process: EBW is a clean process with no filler materials or fluxes, reducing the risk of contamination.

-

High Welding Speed: The process is fast, which increases productivity and reduces manufacturing time.

Challenges of Electron Beam Welding

Despite its advantages, EBW has some challenges that need to be addressed:

-

High Initial Cost: The equipment and setup for EBW are expensive, making it a significant investment.

-

Vacuum Requirement: The need for a vacuum chamber adds complexity and cost to the process.

-

Skilled Operators: Operating EBW equipment requires specialized training and expertise.

-

Limited Material Compatibility: Not all materials are suitable for EBW, limiting its applications.

Technical Aspects of Electron Beam Welding

Understanding the technical aspects of EBW can provide deeper insights into its functionality:

-

Electron Gun: The heart of the EBW system, the electron gun generates and accelerates electrons to high velocities.

-

Focusing System: Magnetic lenses focus the electron beam to a fine point, ensuring precision.

-

Beam Deflection: Electromagnetic coils deflect the beam to control the welding path.

-

Power Supply: A high-voltage power supply is essential to generate the electron beam.

-

Vacuum System: The vacuum system maintains the necessary low-pressure environment for the process.

Safety Considerations in Electron Beam Welding

Safety is paramount in EBW due to the high-energy beams and vacuum environment:

-

Radiation Shielding: Proper shielding is required to protect operators from X-ray radiation generated during the process.

-

Vacuum Integrity: Ensuring the vacuum chamber's integrity is crucial to prevent accidents and maintain process quality.

-

High Voltage Safety: Operators must be trained to handle high-voltage equipment safely.

-

Emergency Protocols: Clear emergency protocols should be in place to address any incidents promptly.

Innovations in Electron Beam Welding

Recent advancements have further enhanced the capabilities of EBW:

-

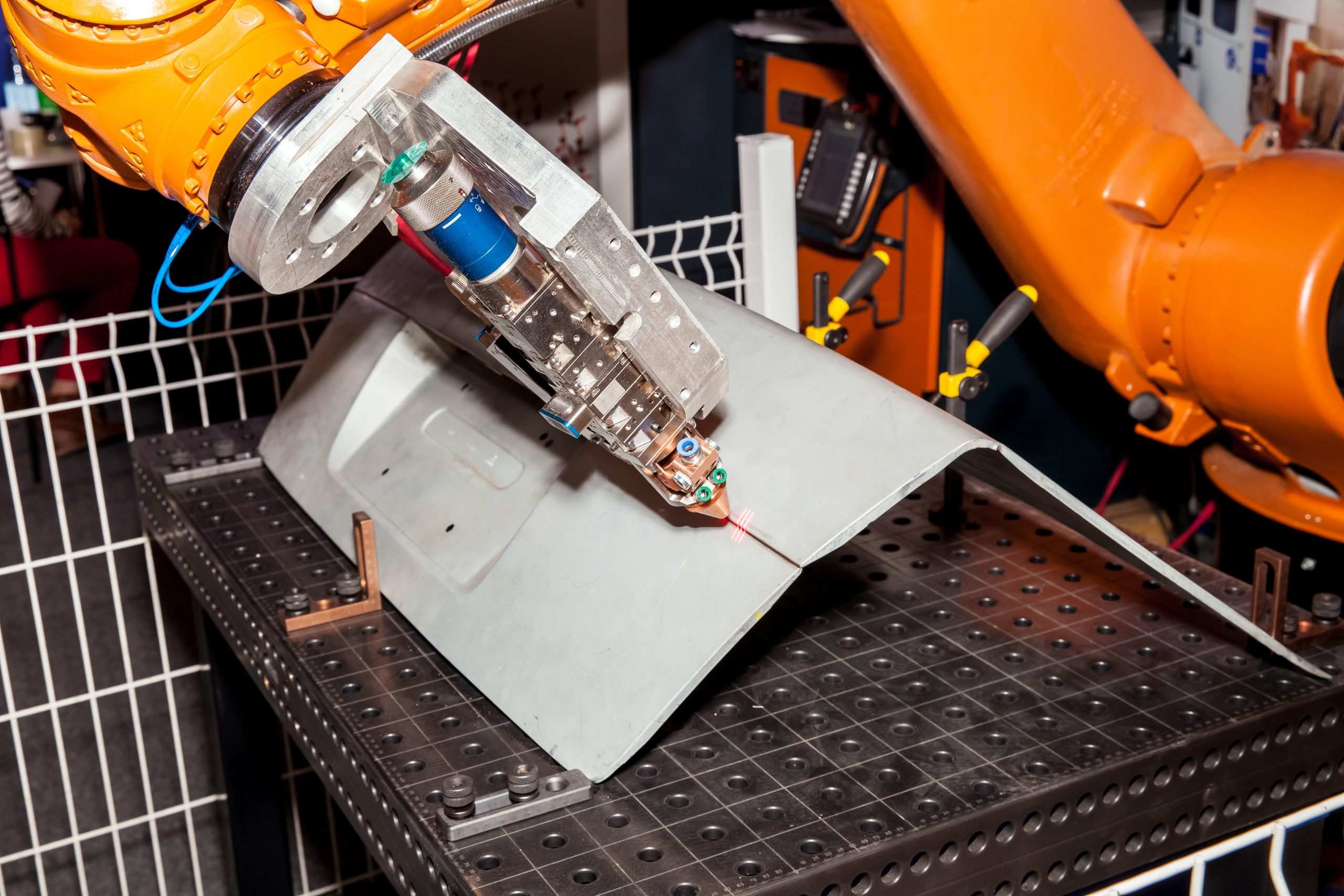

Hybrid Welding: Combining EBW with other welding techniques, like laser welding, improves efficiency and quality.

-

Automation: Integrating robotics and automation has increased precision and reduced human error.

-

Real-Time Monitoring: Advanced sensors and monitoring systems allow for real-time quality control during the welding process.

-

Portable EBW Systems: Development of portable EBW systems has expanded its applications to fieldwork and remote locations.

-

Material Innovations: Research into new materials compatible with EBW continues to broaden its industrial applications.

Final Thoughts on Electron Beam Welding

Electron beam welding (EBW) stands out as a game-changer in the world of manufacturing. Its precision, efficiency, and ability to join dissimilar metals make it invaluable for industries ranging from aerospace to automotive. The process involves using a focused beam of electrons to melt and fuse materials, resulting in strong, high-quality welds. Despite its high initial cost, the long-term benefits, such as reduced material waste and enhanced product durability, make it a worthwhile investment. EBW's capability to operate in a vacuum environment ensures minimal contamination, leading to cleaner welds. As technology advances, EBW will likely become even more accessible and versatile. Understanding these key aspects of EBW can help industries make informed decisions about incorporating this innovative welding technique into their production processes. Embracing EBW could lead to significant advancements in manufacturing efficiency and product quality.

Was this page helpful?

Our commitment to delivering trustworthy and engaging content is at the heart of what we do. Each fact on our site is contributed by real users like you, bringing a wealth of diverse insights and information. To ensure the highest standards of accuracy and reliability, our dedicated editors meticulously review each submission. This process guarantees that the facts we share are not only fascinating but also credible. Trust in our commitment to quality and authenticity as you explore and learn with us.