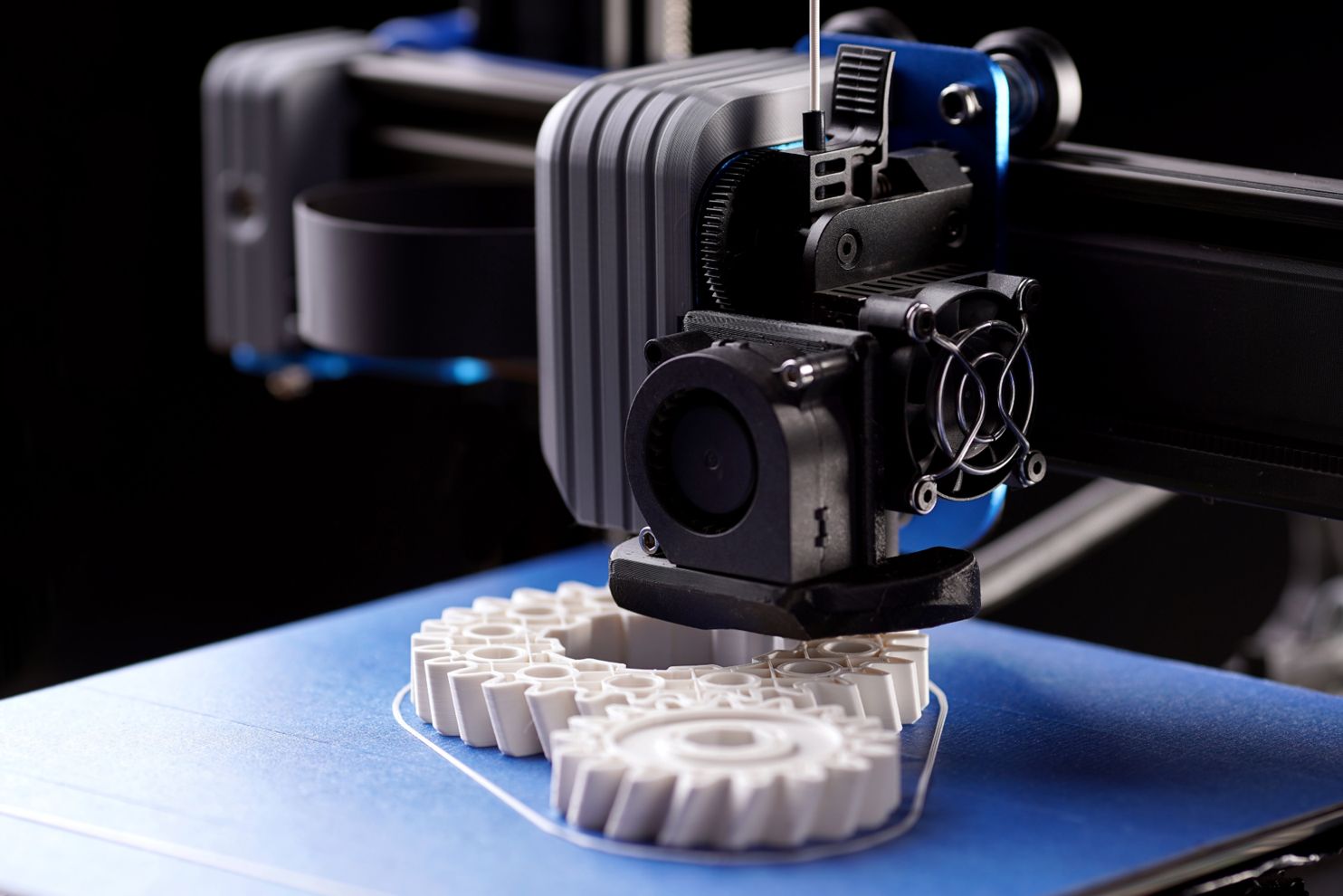

Material extrusion is a fascinating process used in 3D printing, where material is pushed through a nozzle to create objects layer by layer. But what makes it so special? For starters, it's one of the most accessible and affordable methods for creating 3D printed items. Whether you're a hobbyist or a professional, material extrusion offers a versatile way to bring your ideas to life. From simple toys to complex prototypes, this technique can handle a wide range of projects. Want to know more? Here are 31 intriguing facts about material extrusion that will deepen your understanding and appreciation of this amazing technology.

What is Material Extrusion?

Material extrusion, often known as Fused Deposition Modeling (FDM) or Fused Filament Fabrication (FFF), is a popular 3D printing method. It involves pushing a thermoplastic filament through a heated nozzle, which melts and deposits the material layer by layer to create an object. This technique is widely used due to its simplicity and affordability.

- Material extrusion is one of the most accessible 3D printing technologies available today.

- The process uses thermoplastic filaments, which are heated and extruded through a nozzle.

- FDM and FFF are the most common terms associated with material extrusion.

- The technology was first developed in the late 1980s by Scott Crump, co-founder of Stratasys.

How Material Extrusion Works

Understanding how material extrusion works can help appreciate its applications and limitations. The process involves several steps, each crucial for creating a successful print.

- The filament is fed into the extruder, where it is heated to its melting point.

- The melted filament is then extruded through a nozzle onto the build platform.

- The nozzle moves in a predetermined path, depositing material layer by layer.

- Each layer cools and solidifies before the next layer is added, ensuring structural integrity.

Types of Materials Used

Material extrusion can work with various thermoplastics, each offering different properties and applications. Knowing the types of materials can help in selecting the right one for specific projects.

- PLA (Polylactic Acid) is a popular choice due to its ease of use and biodegradability.

- ABS (Acrylonitrile Butadiene Styrene) is known for its strength and durability.

- PETG (Polyethylene Terephthalate Glycol) combines the ease of PLA with the strength of ABS.

- TPU (Thermoplastic Polyurethane) is flexible and often used for making rubber-like parts.

Applications of Material Extrusion

Material extrusion has a wide range of applications, from prototyping to creating functional parts. Its versatility makes it a valuable tool in various industries.

- Prototyping is one of the most common uses, allowing designers to quickly create and test models.

- Education benefits from material extrusion by providing hands-on learning experiences.

- Medical applications include creating custom prosthetics and anatomical models.

- Automotive industries use it for making custom parts and tools.

Advantages of Material Extrusion

There are several reasons why material extrusion is a preferred method for 3D printing. Its benefits make it an attractive option for hobbyists and professionals alike.

- Affordability is a significant advantage, making it accessible to a wide audience.

- Ease of use allows even beginners to start printing with minimal training.

- Versatility in materials means it can be used for various applications.

- Scalability allows for both small and large-scale production.

Challenges and Limitations

Despite its many advantages, material extrusion also has some challenges and limitations. Being aware of these can help in making informed decisions about its use.

- Layer lines can be visible, affecting the surface finish of the printed object.

- Warping can occur, especially with materials like ABS, due to uneven cooling.

- Support structures are often needed for overhangs, adding to post-processing time.

- Print speed can be slower compared to other 3D printing technologies.

Innovations in Material Extrusion

The field of material extrusion is continually evolving, with new innovations improving its capabilities and expanding its applications.

- Multi-material printing allows for combining different materials in a single print.

- Improved nozzles and extruders enhance print quality and reliability.

- Advanced software provides better control over print settings and optimization.

- Recycled filaments are becoming more popular, promoting sustainability.

Future of Material Extrusion

The future of material extrusion looks promising, with ongoing research and development paving the way for new possibilities. Keeping an eye on these trends can provide insights into where the technology is headed.

- Bioprinting using material extrusion is being explored for creating tissue and organ models.

- Large-scale printing is becoming feasible, opening up new industrial applications.

- Smart materials that change properties in response to environmental conditions are being developed.

Final Thoughts on Material Extrusion

Material extrusion, a cornerstone of 3D printing, has revolutionized manufacturing. This technique, known for its versatility and cost-effectiveness, allows for the creation of complex designs with ease. From prototyping to producing end-use parts, material extrusion offers endless possibilities. Its ability to work with a variety of materials, including plastics and composites, makes it a go-to choice for many industries.

Understanding the nuances of material extrusion can help you make informed decisions about its applications. Whether you're a hobbyist or a professional, knowing the ins and outs of this technology can open up new avenues for creativity and innovation. So, next time you think about 3D printing, remember the power of material extrusion. It's not just a method; it's a gateway to endless possibilities. Dive in and explore what you can create!

Was this page helpful?

Our commitment to delivering trustworthy and engaging content is at the heart of what we do. Each fact on our site is contributed by real users like you, bringing a wealth of diverse insights and information. To ensure the highest standards of accuracy and reliability, our dedicated editors meticulously review each submission. This process guarantees that the facts we share are not only fascinating but also credible. Trust in our commitment to quality and authenticity as you explore and learn with us.