What is a PID controller? A PID controller stands for Proportional-Integral-Derivative controller. It's a type of feedback loop mechanism widely used in industrial control systems. Why is it important? It helps maintain the desired output of a system by minimizing the difference between the setpoint and the process variable. How does it work? The PID controller adjusts the control inputs based on three terms: proportional, integral, and derivative. Each term addresses different aspects of the error. Where is it used? You'll find PID controllers in applications like temperature control, motor speed regulation, and even in drones. Why should you care? Understanding PID controllers can help you grasp how many automated systems around us function efficiently.

What is a PID Controller?

A PID controller is a control loop mechanism widely used in industrial control systems. PID stands for Proportional, Integral, and Derivative, which are the three basic coefficients used in the algorithm. These controllers are essential for maintaining the desired output of a system by minimizing the error between the setpoint and the process variable.

-

PID controllers are used in various applications, including temperature control, speed control, and flow control.

-

The Proportional component of a PID controller determines the reaction to the current error.

-

The Integral component sums up past errors to eliminate residual steady-state errors.

-

The Derivative component predicts future errors based on the rate of change.

History of PID Controllers

Understanding the history of PID controllers helps appreciate their development and significance in modern technology.

-

The concept of PID control dates back to the 19th century when James Clerk Maxwell described the theoretical basis for control systems.

-

The first practical application of PID control was in the 1920s, used in automatic steering systems for ships.

-

In 1942, John Ziegler and Nathaniel Nichols developed the Ziegler-Nichols method for tuning PID controllers, which is still widely used today.

How PID Controllers Work

The working principle of PID controllers involves continuous calculation and adjustment to maintain system stability.

-

PID controllers continuously calculate the error value as the difference between a desired setpoint and a measured process variable.

-

The controller applies a correction based on proportional, integral, and derivative terms to minimize the error.

-

Tuning a PID controller involves setting the optimal values for the proportional, integral, and derivative gains.

Applications of PID Controllers

PID controllers are versatile and find applications in various fields, from industrial processes to everyday gadgets.

-

In the automotive industry, PID controllers manage engine speed and fuel injection systems.

-

HVAC systems use PID controllers to maintain comfortable indoor temperatures.

-

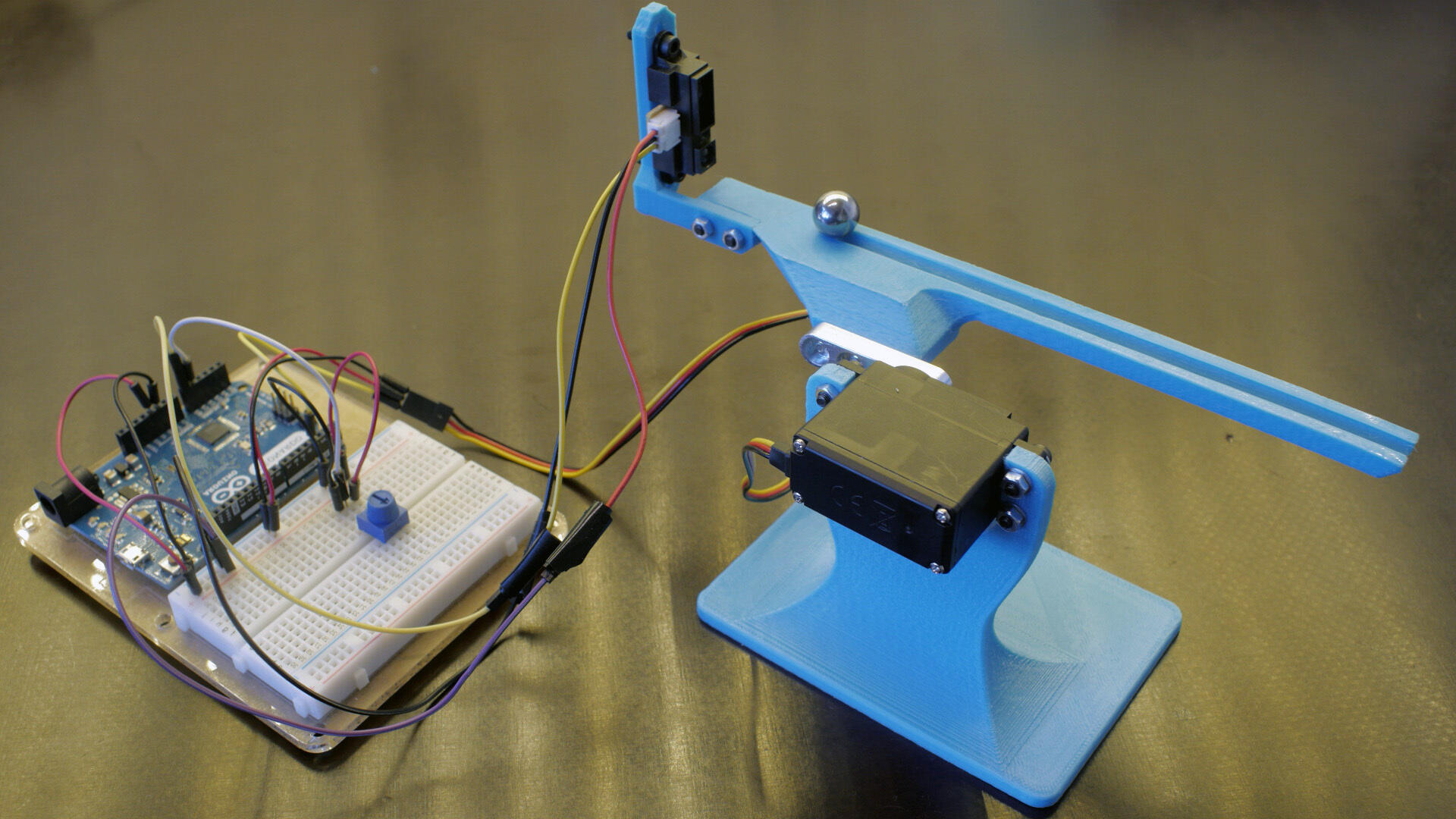

Robotics relies on PID controllers for precise movement and positioning.

-

In chemical processing, PID controllers regulate flow rates, temperatures, and pressures.

Advantages of PID Controllers

PID controllers offer several benefits that make them a popular choice in control systems.

-

They provide accurate and stable control, reducing the risk of system instability.

-

PID controllers are relatively simple to implement and understand.

-

They can handle a wide range of operating conditions and disturbances.

-

The flexibility of PID controllers allows them to be used in various applications without significant modifications.

Challenges in Using PID Controllers

Despite their advantages, PID controllers also present some challenges that need to be addressed.

-

Tuning PID controllers can be complex and time-consuming, requiring expertise and experience.

-

Improper tuning can lead to poor performance, oscillations, or even system instability.

-

PID controllers may struggle with non-linear systems or systems with significant time delays.

Modern Developments in PID Controllers

Advancements in technology have led to improvements and new approaches in PID control.

-

Digital PID controllers offer enhanced precision and flexibility compared to their analog counterparts.

-

Adaptive PID controllers can adjust their parameters in real-time to handle changing system dynamics.

-

Fuzzy logic and neural network-based PID controllers provide improved performance in complex and non-linear systems.

Real-World Examples of PID Controllers

Seeing PID controllers in action helps understand their practical applications and benefits.

-

In drones, PID controllers stabilize flight by adjusting motor speeds based on sensor inputs.

-

3D printers use PID controllers to maintain consistent temperatures for precise printing.

-

In medical devices, PID controllers regulate the flow of fluids and gases to ensure patient safety and comfort.

The Power of PID Controllers

PID controllers are essential in modern automation. They help maintain stability, accuracy, and efficiency in various systems. From industrial machines to home thermostats, these controllers ensure everything runs smoothly. Understanding their components—Proportional, Integral, and Derivative—can help you appreciate their role in everyday technology.

Their versatility makes them invaluable in many fields. Engineers rely on them for precise control in manufacturing, robotics, and even aerospace. The ability to fine-tune processes and respond to changes in real-time sets PID controllers apart from other control methods.

Learning about PID controllers can open doors to new opportunities in tech and engineering. Whether you're a student, hobbyist, or professional, grasping these concepts can enhance your skills and knowledge. So, next time you adjust your thermostat or see a robot in action, remember the PID controller working behind the scenes.

Was this page helpful?

Our commitment to delivering trustworthy and engaging content is at the heart of what we do. Each fact on our site is contributed by real users like you, bringing a wealth of diverse insights and information. To ensure the highest standards of accuracy and reliability, our dedicated editors meticulously review each submission. This process guarantees that the facts we share are not only fascinating but also credible. Trust in our commitment to quality and authenticity as you explore and learn with us.