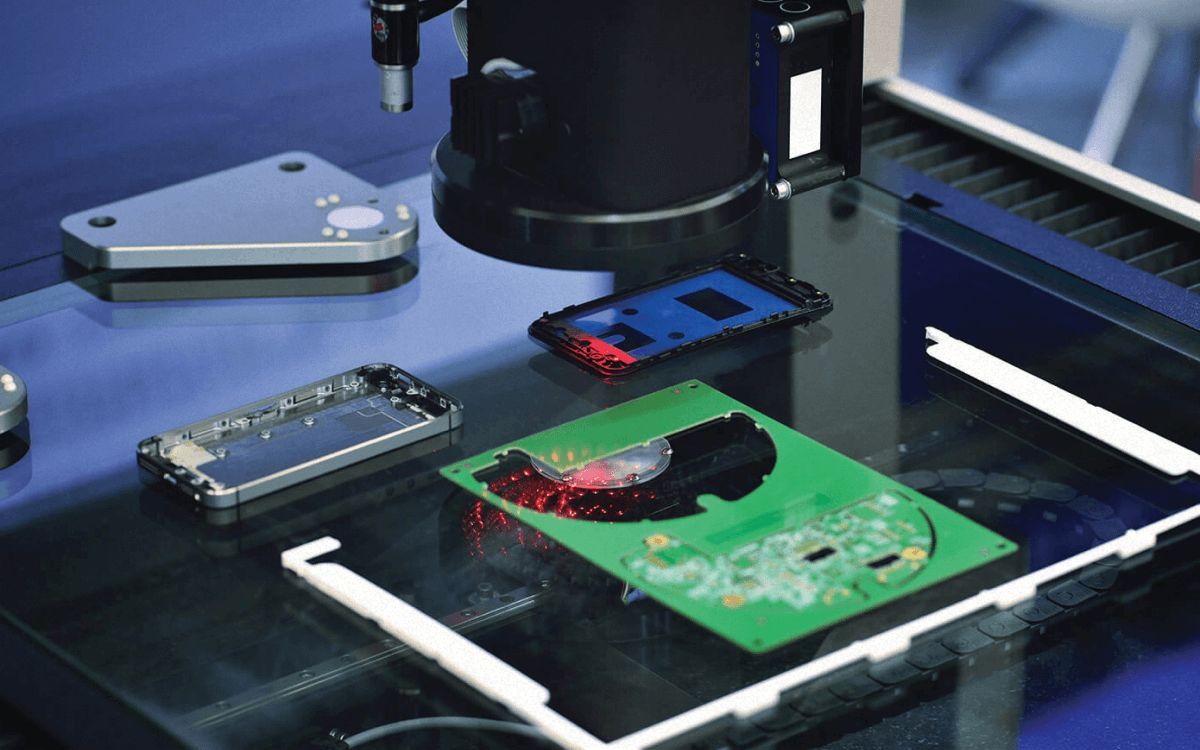

Computer vision in manufacturing is transforming how factories operate, making processes faster, safer, and more efficient. But what exactly is computer vision? It's a technology that enables machines to interpret and make decisions based on visual data, similar to how humans use their eyes and brains. Imagine robots inspecting products for defects, ensuring quality control, or even guiding automated vehicles through a warehouse. This tech isn't just futuristic; it's already here, revolutionizing industries. From reducing human error to increasing production speed, the benefits are immense. Ready to learn more? Here are 27 fascinating facts about computer vision in manufacturing.

What is Computer Vision in Manufacturing?

Computer vision in manufacturing refers to the use of artificial intelligence (AI) and machine learning (ML) to enable machines to interpret and make decisions based on visual data. This technology is transforming the manufacturing industry by improving efficiency, quality, and safety. Here are some fascinating facts about its application.

-

Automated Quality Control

Computer vision systems can inspect products for defects at a speed and accuracy that far surpass human capabilities. This ensures higher quality products and reduces waste. -

Predictive Maintenance

By analyzing visual data from machinery, computer vision can predict when a machine is likely to fail. This allows for timely maintenance, preventing costly breakdowns. -

Enhanced Safety

These systems can monitor factory floors for safety hazards, ensuring that workers are adhering to safety protocols. This reduces the risk of accidents.

How Computer Vision Improves Efficiency

Efficiency is key in manufacturing, and computer vision plays a significant role in optimizing various processes. Here are some ways it boosts efficiency.

-

Real-Time Monitoring

Computer vision provides real-time monitoring of production lines, allowing for immediate adjustments to be made. This minimizes downtime and maximizes productivity. -

Inventory Management

Automated systems can track inventory levels and manage stock more efficiently. This reduces the likelihood of overstocking or stockouts. -

Speedy Sorting

Computer vision can sort products at high speeds, ensuring that only items meeting quality standards proceed to the next stage of production.

Applications in Robotics

Robots equipped with computer vision are becoming increasingly common in manufacturing. They bring precision and reliability to various tasks. Here are some examples.

-

Assembly Line Automation

Robots with computer vision can assemble products with high precision, reducing errors and increasing production speed. -

Material Handling

These robots can identify and handle different materials, ensuring they are placed correctly and safely within the production line. -

Packaging

Computer vision enables robots to package products efficiently, ensuring that each package meets specific standards.

Benefits for Quality Assurance

Quality assurance is critical in manufacturing, and computer vision significantly enhances this aspect. Here’s how.

-

Defect Detection

Computer vision systems can detect even the smallest defects in products, ensuring that only high-quality items reach consumers. -

Consistency

These systems ensure that every product meets the same quality standards, providing consistency across all units produced. -

Traceability

Computer vision can track products through every stage of production, providing a detailed record that can be used for quality control and compliance.

Impact on Labor

The introduction of computer vision in manufacturing has significant implications for labor. Here are some key points.

-

Job Transformation

While some manual jobs may be reduced, new roles in programming, maintenance, and oversight of computer vision systems are created. -

Skill Enhancement

Workers need to acquire new skills to operate and manage these advanced systems, leading to a more skilled workforce. -

Increased Productivity

With repetitive and mundane tasks automated, workers can focus on more complex and creative aspects of manufacturing.

Environmental Benefits

Computer vision also contributes to more sustainable manufacturing practices. Here’s how.

-

Reduced Waste

By ensuring higher quality and fewer defects, computer vision reduces the amount of waste produced in manufacturing. -

Energy Efficiency

Optimized processes and predictive maintenance lead to more efficient use of energy, reducing the overall carbon footprint. -

Resource Management

Better inventory and material handling reduce the need for excess resources, promoting more sustainable practices.

Future Trends

The future of computer vision in manufacturing looks promising, with several exciting trends on the horizon. Here are some to watch.

-

Integration with IoT

Combining computer vision with the Internet of Things (IoT) will enable even smarter and more connected manufacturing environments. -

Advanced AI Algorithms

Continued advancements in AI will make computer vision systems even more accurate and capable. -

Augmented Reality

Augmented reality (AR) combined with computer vision can provide workers with real-time information and guidance, enhancing productivity and safety.

Challenges and Considerations

Despite its benefits, implementing computer vision in manufacturing comes with challenges. Here are some considerations.

-

High Initial Costs

The initial investment in computer vision systems can be high, which may be a barrier for smaller manufacturers. -

Data Privacy

Ensuring the privacy and security of the vast amounts of data collected by these systems is crucial. -

Technical Expertise

Implementing and maintaining these systems requires specialized technical knowledge, which may necessitate additional training for staff.

Real-World Examples

Several companies are already reaping the benefits of computer vision in manufacturing. Here are a few examples.

-

Tesla

Tesla uses computer vision for quality control and to guide robots in the assembly of electric vehicles. -

BMW

BMW employs computer vision to inspect parts and ensure they meet stringent quality standards. -

Foxconn

Foxconn uses computer vision to monitor production lines and detect defects in electronic components.

Computer vision is revolutionizing manufacturing, offering numerous benefits from improved quality control to enhanced efficiency and safety. As technology continues to advance, its impact on the industry will only grow.

The Future of Computer Vision in Manufacturing

Computer vision is transforming manufacturing. From quality control to predictive maintenance, it's making factories smarter and more efficient. This technology helps spot defects, streamline operations, and even predict equipment failures before they happen. It's not just about cutting costs; it's about improving product quality and worker safety.

As more companies adopt computer vision, expect even more innovations. AI and machine learning will continue to enhance its capabilities, making it an indispensable tool in the industry. The benefits are clear: higher productivity, reduced downtime, and better products.

Manufacturers who embrace this technology will stay ahead of the curve. Those who don't risk falling behind. The future of manufacturing is here, and computer vision is leading the way. Get ready for a smarter, more efficient world.

Was this page helpful?

Our commitment to delivering trustworthy and engaging content is at the heart of what we do. Each fact on our site is contributed by real users like you, bringing a wealth of diverse insights and information. To ensure the highest standards of accuracy and reliability, our dedicated editors meticulously review each submission. This process guarantees that the facts we share are not only fascinating but also credible. Trust in our commitment to quality and authenticity as you explore and learn with us.