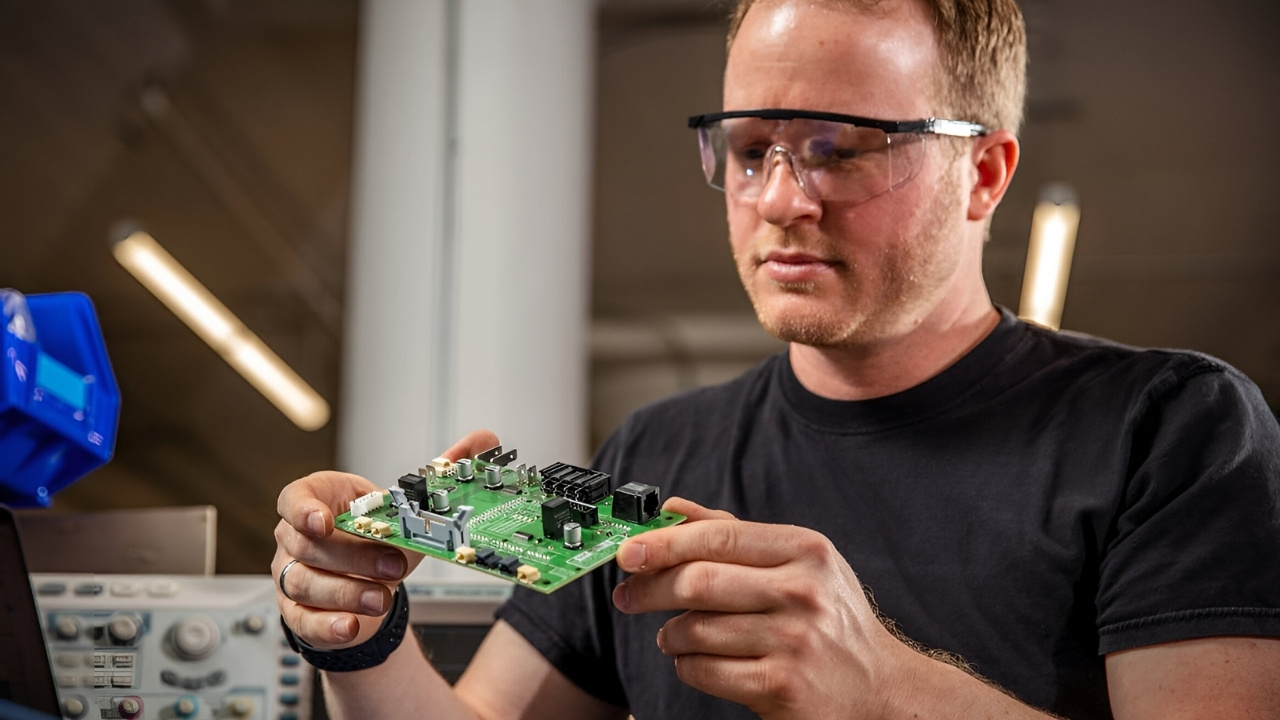

What is PCB design? It's the process of creating the layout for printed circuit boards (PCBs), which are essential components in almost all electronic devices. These boards connect electronic components using conductive pathways, allowing devices to function properly. Why is PCB design important? It ensures that electronic devices work efficiently and reliably. A well-designed PCB can improve performance, reduce costs, and enhance the durability of the device. Who uses PCB design? Engineers, hobbyists, and tech enthusiasts all rely on PCB design to bring their electronic projects to life. Whether you're building a simple gadget or a complex machine, understanding PCB design is crucial. Ready to learn more? Let's dive into 30 fascinating facts about PCB design!

What is PCB Design?

Printed Circuit Board (PCB) design is the process of creating a layout for electronic circuits. This involves placing components and routing connections on a board to ensure everything works correctly.

-

PCBs are Everywhere: From smartphones to microwaves, almost every electronic device contains a PCB.

-

Layers Matter: PCBs can have multiple layers. Simple ones have one or two, while complex ones can have up to 12 or more.

-

Copper is Key: Copper is the primary material used for the conductive paths on a PCB.

-

Solder Mask: The green (or sometimes other colors) layer on a PCB is called the solder mask. It protects the copper traces from short circuits.

-

Silkscreen: The white markings on a PCB are called the silkscreen. They help identify components and provide other useful information.

History of PCB Design

Understanding the history of PCB design can give insights into its evolution and importance in modern electronics.

-

First PCBs: The first PCBs were developed in the 1940s for military applications.

-

Paul Eisler: Paul Eisler, an Austrian engineer, is credited with inventing the PCB in 1936.

-

Mass Production: By the 1950s, PCBs were being mass-produced for consumer electronics.

-

Miniaturization: Over the decades, PCBs have become smaller and more efficient, allowing for the miniaturization of electronic devices.

-

Surface Mount Technology (SMT): Introduced in the 1980s, SMT allowed components to be mounted directly onto the surface of the PCB, making assembly faster and more reliable.

Components of a PCB

A PCB is made up of various components, each playing a crucial role in its functionality.

-

Resistors: These control the flow of electric current in a circuit.

-

Capacitors: Capacitors store and release electrical energy.

-

Diodes: Diodes allow current to flow in one direction only, preventing damage to components.

-

Transistors: Transistors amplify electrical signals and act as switches.

-

Integrated Circuits (ICs): ICs are small chips that can perform complex functions, like processing data.

PCB Design Software

Designing a PCB requires specialized software to create accurate and functional layouts.

-

Eagle: Eagle is a popular PCB design software known for its user-friendly interface.

-

KiCad: KiCad is an open-source PCB design tool that is free to use.

-

Altium Designer: Altium Designer is a professional-grade software used by many engineers for complex PCB designs.

-

OrCAD: OrCAD is another widely used PCB design software, especially in the automotive and aerospace industries.

-

EasyEDA: EasyEDA is a web-based PCB design tool that allows for easy collaboration and sharing.

PCB Manufacturing Process

The manufacturing process of a PCB involves several steps to ensure the final product is reliable and functional.

-

Design Verification: Before manufacturing, the design is thoroughly checked for errors.

-

Photolithography: This process transfers the PCB design onto a copper-clad board using light-sensitive chemicals.

-

Etching: Unwanted copper is removed from the board, leaving only the desired copper traces.

-

Drilling: Holes are drilled into the board for component leads and vias.

-

Plating: The drilled holes are plated with copper to ensure electrical connectivity.

PCB Testing and Quality Control

Testing and quality control are essential to ensure the PCB functions correctly and reliably.

-

Automated Optical Inspection (AOI): AOI uses cameras to inspect the PCB for defects.

-

In-Circuit Testing (ICT): ICT checks the electrical performance of the PCB by testing individual components.

-

Functional Testing: This tests the PCB in a real-world scenario to ensure it performs as expected.

-

Burn-In Testing: The PCB is subjected to high temperatures and voltages to identify potential failures.

-

X-Ray Inspection: X-rays are used to inspect the internal layers of the PCB for defects not visible to the naked eye.

The Final Word on PCB Design

PCB design is a fascinating blend of engineering and creativity. From understanding copper traces to mastering multi-layer boards, there's always something new to learn. Design software like Eagle and KiCad make the process smoother, while DFM (Design for Manufacturability) ensures your designs are practical. Remember, thermal management is crucial to avoid overheating. Signal integrity keeps your circuits running smoothly. Prototyping helps catch errors early, saving time and money. Solder masks protect your boards, and vias connect different layers. Whether you're a beginner or a pro, staying updated with the latest trends and technologies is key. Keep experimenting, learning, and pushing the boundaries of what's possible. PCB design isn't just about circuits; it's about innovation and problem-solving. Happy designing!

Was this page helpful?

Our commitment to delivering trustworthy and engaging content is at the heart of what we do. Each fact on our site is contributed by real users like you, bringing a wealth of diverse insights and information. To ensure the highest standards of accuracy and reliability, our dedicated editors meticulously review each submission. This process guarantees that the facts we share are not only fascinating but also credible. Trust in our commitment to quality and authenticity as you explore and learn with us.