Antiphase boundaries might sound like something out of a sci-fi movie, but they play a crucial role in materials science. These boundaries occur when two regions of a crystal structure are out of sync, creating a mismatch. Why should you care? Because understanding them can lead to stronger, more efficient materials. Imagine a world where your smartphone lasts longer or your car is more fuel-efficient. That's the potential impact of mastering antiphase boundaries. In this post, we'll explore 33 fascinating facts about these boundaries, from their formation to their applications. Ready to dive in? Let's get started!

What Are Antiphase Boundaries?

Antiphase boundaries (APBs) are fascinating features in materials science. They occur in ordered alloys and play a crucial role in determining the properties of these materials. Here are some intriguing facts about APBs that will help you understand their significance.

-

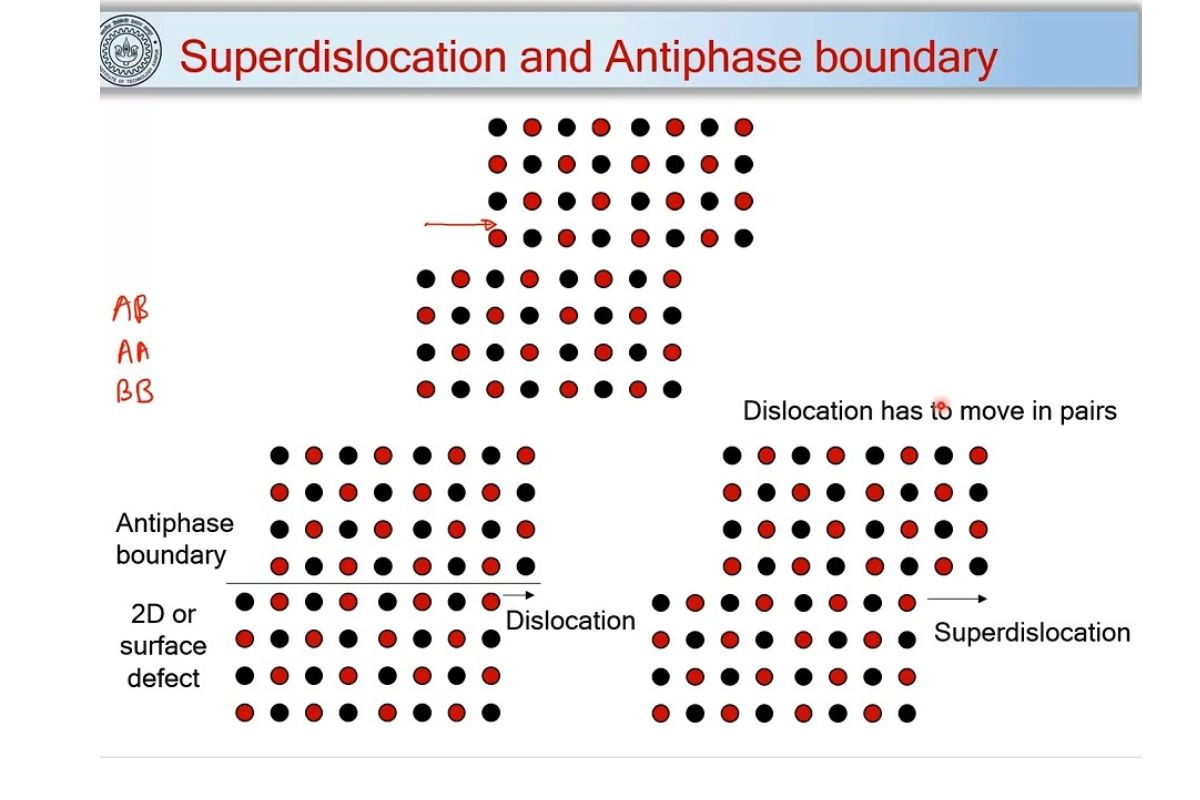

APBs are defects in the crystal structure of ordered alloys. They separate regions where the atomic order is out of phase.

-

They form during phase transitions when a material changes from a disordered to an ordered state. This process can create regions with different atomic arrangements.

-

APBs affect material properties such as electrical conductivity, magnetic behavior, and mechanical strength. Their presence can either enhance or degrade these properties.

-

They are common in superalloys, which are used in high-temperature applications like jet engines. APBs can influence the performance and durability of these materials.

-

APBs can be visualized using advanced microscopy techniques like transmission electron microscopy (TEM). This allows scientists to study their structure and behavior in detail.

How Do Antiphase Boundaries Form?

Understanding the formation of APBs helps in controlling their effects on material properties. Here are some key facts about their formation.

-

APBs form during cooling when an alloy transitions from a high-temperature disordered phase to a low-temperature ordered phase.

-

They can also form during deformation when a material is subjected to stress. This can cause regions of the crystal to shift out of phase.

-

The cooling rate affects APB formation. Rapid cooling can lead to a higher density of APBs, while slow cooling allows for more ordered regions.

-

APBs can migrate within the crystal structure. This movement can be driven by thermal energy or applied stress.

-

The presence of impurities can influence APB formation. Certain elements can stabilize or destabilize the ordered phase, affecting the density and distribution of APBs.

Effects of Antiphase Boundaries on Material Properties

APBs have a significant impact on the properties of materials. Here are some ways they influence various characteristics.

-

APBs can increase hardness by hindering the movement of dislocations. This makes the material more resistant to deformation.

-

They can reduce electrical conductivity by scattering electrons. This is particularly important in materials used for electronic applications.

-

APBs can affect magnetic properties. In magnetic materials, they can disrupt the alignment of magnetic domains, altering the material's overall magnetism.

-

They can influence thermal conductivity. APBs can scatter phonons, which are responsible for heat conduction in materials.

-

APBs can enhance creep resistance. In high-temperature applications, they can slow down the rate of deformation under constant stress.

Techniques to Control Antiphase Boundaries

Controlling APBs is crucial for optimizing material properties. Here are some methods used to manage their formation and behavior.

-

Heat treatment can be used to control APB density. By carefully controlling the cooling rate, the number of APBs can be minimized.

-

Alloying elements can be added to stabilize the ordered phase. Elements like aluminum and titanium can help reduce the formation of APBs.

-

Mechanical processing such as rolling or forging can influence APB distribution. These processes can break up large APB regions and create a more uniform structure.

-

Annealing can help reduce APB density. By heating the material to a high temperature and then slowly cooling it, APBs can be eliminated or reduced.

-

Quenching can be used to control APB formation. Rapid cooling from a high temperature can trap the material in a disordered state, reducing the number of APBs.

Real-World Applications of Antiphase Boundaries

APBs are not just a theoretical concept; they have practical implications in various industries. Here are some examples of their real-world applications.

-

Jet engines use superalloys with controlled APBs to withstand high temperatures and stresses.

-

Magnetic storage devices rely on materials with specific magnetic properties, which can be influenced by APBs.

-

Semiconductors use materials with controlled APBs to optimize electrical conductivity and performance.

-

Nuclear reactors use materials with high creep resistance, which can be enhanced by controlling APBs.

-

Turbine blades in power plants use superalloys with controlled APBs to improve durability and performance.

Challenges in Studying Antiphase Boundaries

Studying APBs presents several challenges due to their complex nature. Here are some of the difficulties researchers face.

-

APBs are nanoscale features, making them difficult to observe and analyze.

-

Their formation is influenced by multiple factors, including temperature, stress, and alloy composition.

-

APBs can migrate, making it challenging to study their behavior over time.

-

Advanced microscopy techniques are required to visualize APBs, which can be expensive and time-consuming.

-

Simulating APBs in computational models is complex due to the need to account for various interactions and factors.

Future Directions in Antiphase Boundary Research

Research on APBs continues to evolve, with new discoveries and techniques emerging. Here are some potential future directions in this field.

-

Developing new alloys with controlled APB formation to optimize material properties for specific applications.

-

Improving microscopy techniques to better visualize and analyze APBs at the nanoscale.

-

Using machine learning to predict APB formation and behavior based on alloy composition and processing conditions.

The Final Word on Antiphase Boundaries

Antiphase boundaries (APBs) are fascinating features in materials science. They play a crucial role in determining the properties of alloys and other compounds. Understanding APBs helps scientists develop stronger, more durable materials. These boundaries occur when there is a shift in the arrangement of atoms, leading to unique properties.

APBs can affect electrical conductivity, magnetism, and mechanical strength. Researchers study them to improve everything from jet engines to electronic devices. Knowing how to control APBs can lead to innovations in technology and industry.

In short, antiphase boundaries are more than just a scientific curiosity. They hold the key to advancements in various fields. By continuing to explore and understand APBs, we can unlock new possibilities for the future. Keep an eye on this area of research; it's bound to lead to exciting developments.

Was this page helpful?

Our commitment to delivering trustworthy and engaging content is at the heart of what we do. Each fact on our site is contributed by real users like you, bringing a wealth of diverse insights and information. To ensure the highest standards of accuracy and reliability, our dedicated editors meticulously review each submission. This process guarantees that the facts we share are not only fascinating but also credible. Trust in our commitment to quality and authenticity as you explore and learn with us.