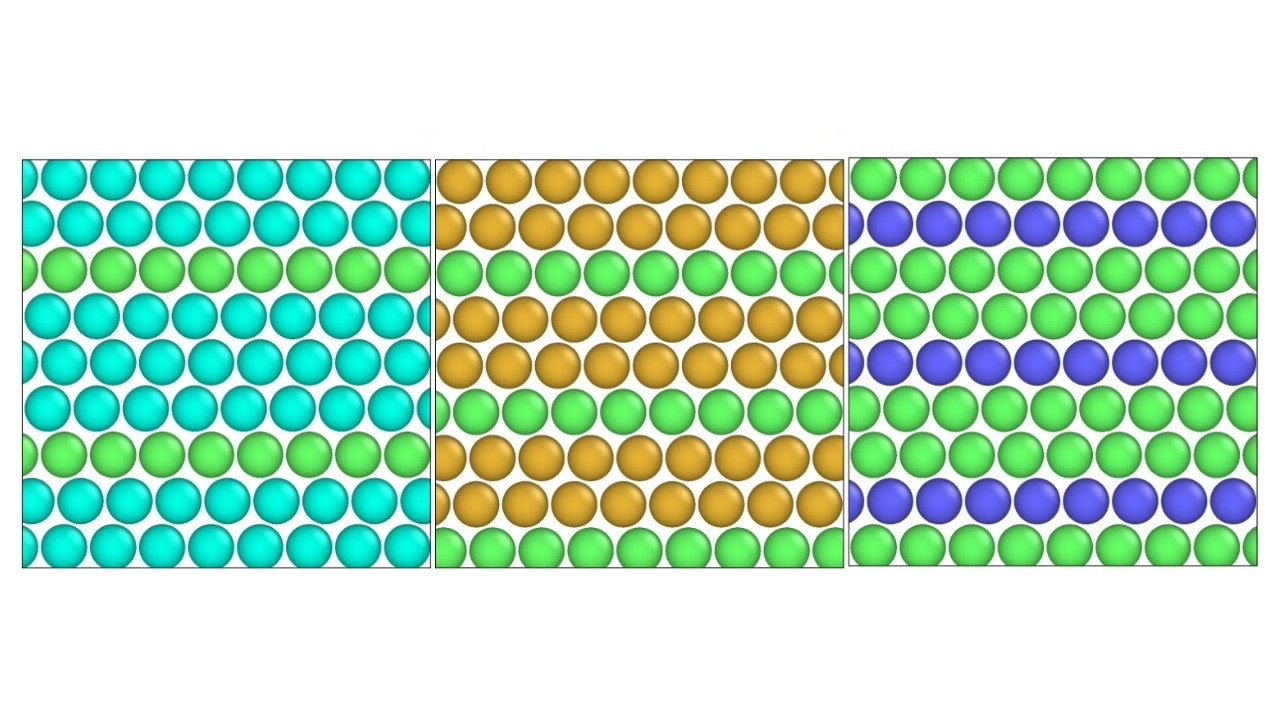

What are stacking faults? Stacking faults are disruptions in the regular atomic arrangement within a crystal structure. Imagine a neat stack of oranges at the grocery store. If one orange is out of place, the whole stack looks off. Similarly, in crystals, these faults can affect properties like strength, conductivity, and even color. Why do they matter? Because they can influence the performance of materials in electronics, aerospace, and other high-tech industries. Understanding stacking faults helps scientists and engineers create better, more reliable materials. Curious to learn more? Let's dive into 27 fascinating facts about stacking faults that will make you see materials in a whole new light!

What Are Stacking Faults?

Stacking faults are disruptions in the regular atomic structure of crystals. These imperfections can affect the properties of materials, making them a fascinating subject for scientists and engineers.

-

Stacking faults occur when the regular sequence of atomic layers is interrupted. This disruption can change the material's mechanical and electrical properties.

-

They are common in metals and alloys. Materials like aluminum, copper, and steel often exhibit these faults due to their crystalline structures.

-

Stacking faults can be intrinsic or extrinsic. Intrinsic faults happen within the crystal itself, while extrinsic faults are caused by external factors like impurities.

How Do Stacking Faults Form?

Understanding the formation of stacking faults helps in controlling and utilizing them in various applications.

-

They can form during crystal growth. As crystals grow, irregularities can develop, leading to stacking faults.

-

Mechanical deformation can cause stacking faults. When a material is bent, stretched, or compressed, the atomic layers can shift, creating faults.

-

Thermal processes can induce stacking faults. Heating and cooling cycles can cause atoms to move, resulting in these imperfections.

Effects of Stacking Faults on Material Properties

Stacking faults can significantly impact the properties of materials, influencing their performance in various applications.

-

They can strengthen materials. In some cases, stacking faults can hinder the movement of dislocations, making the material stronger.

-

Electrical properties can be altered. Stacking faults can change the way electrons move through a material, affecting its conductivity.

-

They can influence magnetic properties. In magnetic materials, stacking faults can affect the alignment of magnetic domains.

Detecting Stacking Faults

Identifying stacking faults is crucial for material scientists to understand and improve material properties.

-

X-ray diffraction can detect stacking faults. This technique reveals disruptions in the crystal structure by analyzing the diffraction patterns.

-

Transmission electron microscopy (TEM) is another method. TEM provides high-resolution images of the atomic structure, making it easier to spot faults.

-

Electron backscatter diffraction (EBSD) is also used. EBSD maps the crystallographic orientation of materials, highlighting areas with stacking faults.

Applications of Stacking Faults

Stacking faults are not just imperfections; they can be harnessed for various technological applications.

-

They are used in semiconductor devices. Stacking faults can influence the electronic properties of semiconductors, making them useful in devices like transistors.

-

In nanotechnology, stacking faults play a role. Nanomaterials with controlled stacking faults can exhibit unique properties, useful in sensors and catalysts.

-

They are important in metallurgy. Understanding and controlling stacking faults can lead to the development of stronger, more durable metals.

Stacking Fault Energy (SFE)

Stacking fault energy is a critical concept in understanding the behavior of stacking faults in materials.

-

SFE measures the energy required to create a stacking fault. Lower SFE means faults form more easily, while higher SFE indicates they are less likely.

-

Materials with low SFE are more ductile. These materials can deform more easily, making them useful in applications requiring flexibility.

-

High SFE materials are typically stronger. These materials resist deformation, making them ideal for structural applications.

Real-World Examples of Stacking Faults

Stacking faults are not just theoretical; they occur in many real-world materials and applications.

-

In aluminum alloys, stacking faults are common. These faults can influence the strength and ductility of the alloy.

-

Copper exhibits stacking faults. These faults can affect the electrical conductivity and mechanical properties of copper.

-

Silicon wafers used in electronics can have stacking faults. These faults can impact the performance of semiconductor devices.

Challenges in Studying Stacking Faults

Despite their importance, studying stacking faults presents several challenges.

-

They are often difficult to detect. Stacking faults can be very small, requiring advanced techniques to identify them.

-

Their formation can be unpredictable. Various factors like temperature, pressure, and impurities can influence the formation of stacking faults.

-

Modeling stacking faults is complex. Simulating the behavior of stacking faults in materials requires sophisticated computational methods.

Future Research on Stacking Faults

Ongoing research aims to better understand and control stacking faults for advanced material applications.

-

New detection methods are being developed. Improved techniques will make it easier to identify and study stacking faults.

-

Researchers are exploring ways to control stacking faults. By manipulating factors like temperature and pressure, scientists hope to create materials with desired properties.

-

The role of stacking faults in nanomaterials is a growing field. Understanding how these faults affect nanomaterials could lead to breakthroughs in technology and medicine.

Final Thoughts on Stacking Faults

Stacking faults might seem like a niche topic, but they play a crucial role in materials science. These defects can influence the mechanical properties of metals and alloys, affecting everything from their strength to their ductility. Understanding stacking faults helps engineers and scientists develop better materials for various applications, from aerospace to electronics.

By studying these imperfections, researchers can predict how materials will behave under stress, leading to innovations in design and manufacturing. Whether you're a student, a professional, or just curious, knowing about stacking faults gives you a deeper appreciation for the complexity of the materials around us.

So next time you encounter a piece of metal or an electronic device, remember the tiny faults that might be at play. They’re not just flaws; they’re opportunities for improvement and innovation in the world of materials science.

Was this page helpful?

Our commitment to delivering trustworthy and engaging content is at the heart of what we do. Each fact on our site is contributed by real users like you, bringing a wealth of diverse insights and information. To ensure the highest standards of accuracy and reliability, our dedicated editors meticulously review each submission. This process guarantees that the facts we share are not only fascinating but also credible. Trust in our commitment to quality and authenticity as you explore and learn with us.