Dynamic recrystallization is a fascinating process that occurs in materials science, particularly in metals and alloys. But what exactly is dynamic recrystallization? Dynamic recrystallization happens when new grains form in a material while it is being deformed, usually at high temperatures. This process can significantly alter the material's properties, making it stronger, more ductile, or even more resistant to wear. Understanding dynamic recrystallization is crucial for industries like aerospace, automotive, and manufacturing, where material performance is key. In this post, we'll dive into 25 intriguing facts about dynamic recrystallization that will help you grasp its importance and applications. Buckle up for a journey through the microscopic world of grains and boundaries!

What is Dynamic Recrystallization?

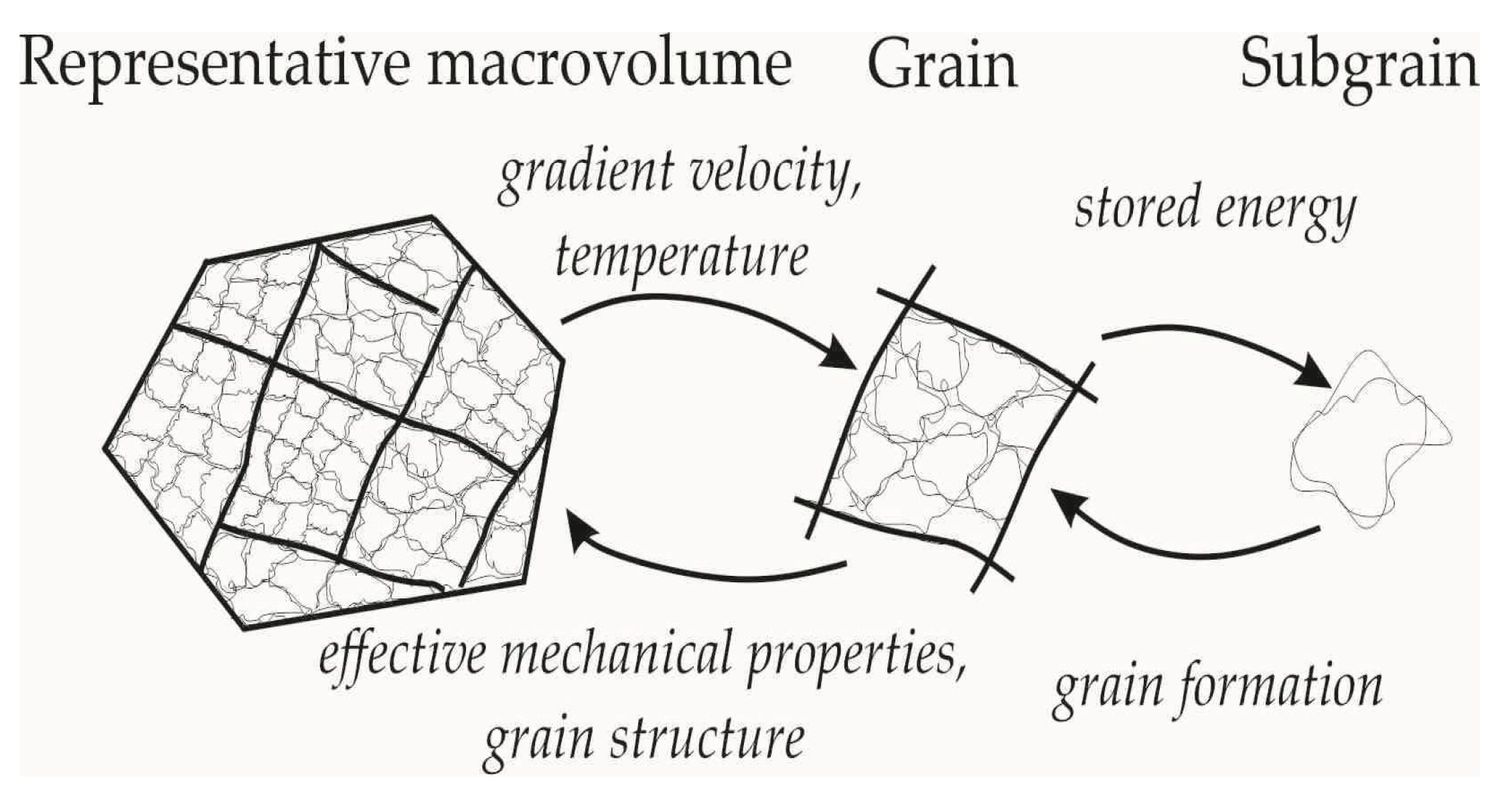

Dynamic recrystallization (DRX) is a fascinating process that occurs in metals and minerals under high temperatures and stress. This phenomenon plays a crucial role in shaping the microstructure of materials, influencing their mechanical properties. Let's dive into some intriguing facts about dynamic recrystallization.

-

Occurs During Deformation

DRX happens when a material undergoes plastic deformation at elevated temperatures. The process helps in reducing internal stresses and refining the grain structure. -

Grain Boundary Migration

During DRX, grain boundaries move to reduce the overall energy of the system. This migration helps in forming new, strain-free grains. -

Nucleation of New Grains

New grains nucleate at sites of high dislocation density. These sites act as catalysts for the formation of new, strain-free grains. -

Temperature Dependent

The occurrence of DRX is highly dependent on temperature. Higher temperatures facilitate the process, making it more efficient. -

Influences Material Strength

DRX can significantly influence the strength and ductility of materials. It often results in a finer grain structure, which enhances mechanical properties.

Mechanisms Behind Dynamic Recrystallization

Understanding the mechanisms behind DRX can provide deeper insights into how materials behave under stress and high temperatures. Here are some key mechanisms involved.

-

Dislocation Climb

Dislocation climb is a critical mechanism in DRX. It allows dislocations to move out of their slip planes, facilitating the formation of new grains. -

Subgrain Rotation

Subgrain rotation helps in the alignment of dislocations, leading to the formation of low-angle grain boundaries that eventually transform into high-angle boundaries. -

Grain Boundary Bulging

Grain boundary bulging occurs when parts of a grain boundary move outward, creating new grains. This is often seen in materials with high stacking fault energy. -

Twining

Twinning is another mechanism where a portion of the crystal lattice forms a mirror image of itself. This can also contribute to the nucleation of new grains. -

Dynamic Recovery

Dynamic recovery competes with DRX by reducing dislocation density without forming new grains. However, it often precedes DRX in many materials.

Factors Affecting Dynamic Recrystallization

Several factors can influence the occurrence and efficiency of DRX. Understanding these factors can help in controlling the process for desired material properties.

-

Strain Rate

Higher strain rates can accelerate DRX by increasing dislocation density, which promotes nucleation of new grains. -

Initial Grain Size

Smaller initial grain sizes can enhance DRX by providing more grain boundary area for nucleation. -

Material Composition

The chemical composition of a material can significantly affect its DRX behavior. Elements like carbon and nitrogen can either promote or inhibit the process. -

Stacking Fault Energy

Materials with high stacking fault energy tend to undergo DRX more readily due to easier dislocation movement. -

Presence of Second Phases

Second phases, like precipitates or inclusions, can either hinder or promote DRX depending on their nature and distribution.

Applications of Dynamic Recrystallization

DRX is not just a laboratory curiosity; it has practical applications in various industries. Here are some areas where DRX plays a crucial role.

-

Metal Forming

DRX is essential in metal forming processes like rolling, forging, and extrusion. It helps in refining the grain structure, improving mechanical properties. -

Welding

During welding, DRX can occur in the heat-affected zone, influencing the final properties of the weld. -

Additive Manufacturing

In additive manufacturing, DRX can help in achieving a fine-grained microstructure, enhancing the mechanical properties of the printed parts. -

Geology

DRX is also observed in geological processes, affecting the texture and properties of rocks and minerals. -

Aerospace Industry

The aerospace industry leverages DRX to produce high-strength, lightweight components with superior mechanical properties.

Challenges in Studying Dynamic Recrystallization

Despite its importance, studying DRX presents several challenges. Here are some of the hurdles researchers face.

-

Complexity of Mechanisms

The multiple mechanisms involved in DRX make it challenging to study and model accurately. -

High-Temperature Experiments

Conducting experiments at the high temperatures required for DRX can be technically demanding and expensive. -

Real-Time Observation

Observing DRX in real-time is difficult due to the rapid nature of the process and the harsh conditions under which it occurs. -

Material Variability

Different materials exhibit different DRX behaviors, making it hard to generalize findings across various substances. -

Computational Modeling

Developing accurate computational models to simulate DRX is complex due to the numerous variables involved.

Dynamic recrystallization remains a captivating subject with significant implications for material science and engineering. Understanding this process can lead to advancements in various industries, from aerospace to geology.

Final Thoughts on Dynamic Recrystallization

Dynamic recrystallization (DRX) is a fascinating process that plays a crucial role in materials science. It involves the formation of new grains in a material under stress, which can significantly alter its properties. Understanding DRX helps in improving the mechanical properties of metals, making them stronger and more durable. This process is essential in industries like aerospace, automotive, and construction, where material performance is critical.

By studying DRX, scientists can develop new alloys and improve existing ones, leading to advancements in technology and engineering. The process also provides insights into how materials behave under extreme conditions, which is valuable for designing safer and more efficient structures.

In summary, dynamic recrystallization is not just a scientific curiosity but a practical tool that impacts various fields. Its study continues to drive innovation and improve the quality of materials we rely on every day.

Was this page helpful?

Our commitment to delivering trustworthy and engaging content is at the heart of what we do. Each fact on our site is contributed by real users like you, bringing a wealth of diverse insights and information. To ensure the highest standards of accuracy and reliability, our dedicated editors meticulously review each submission. This process guarantees that the facts we share are not only fascinating but also credible. Trust in our commitment to quality and authenticity as you explore and learn with us.