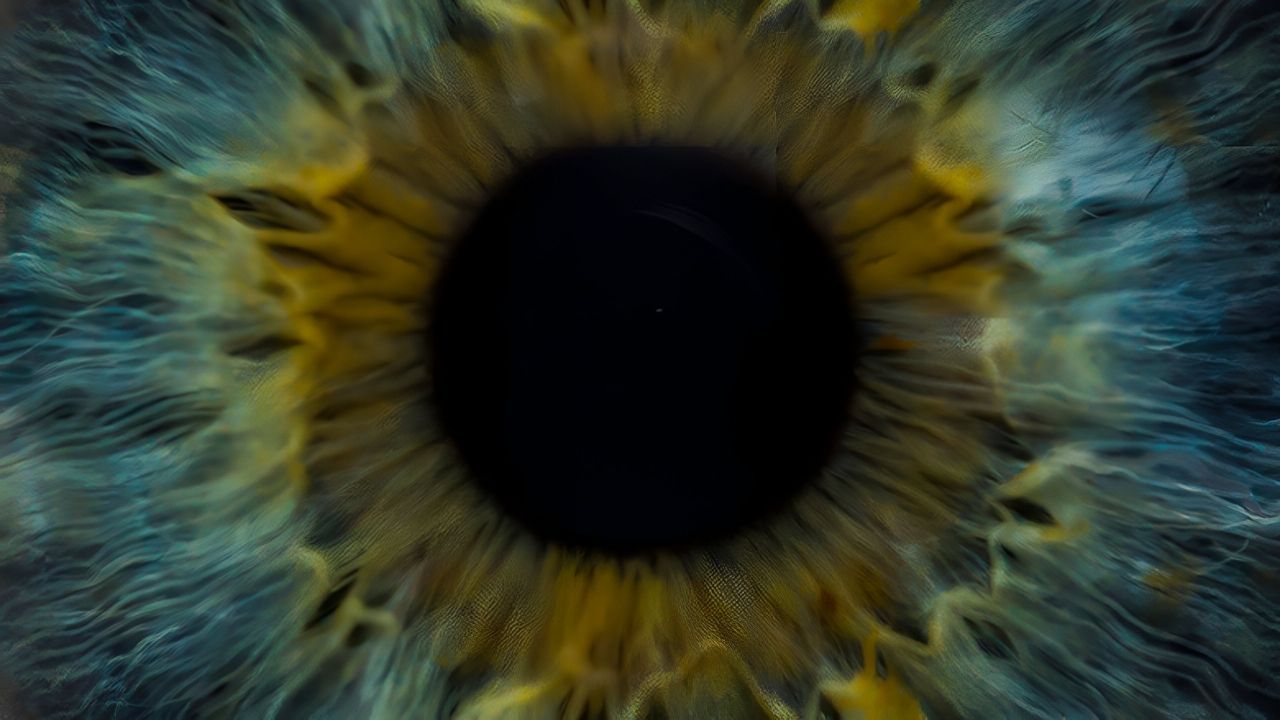

Pigment dispersion plays a crucial role in various industries, from paints to cosmetics. But what exactly is it? Pigment dispersion refers to the process of evenly distributing pigment particles within a medium, ensuring consistent color and quality. This process impacts the final product's appearance, stability, and performance. Imagine trying to mix sugar into your tea; if not done correctly, you end up with clumps. Similarly, poorly dispersed pigments can lead to uneven color and texture. Understanding the importance of pigment dispersion can help in achieving better results in manufacturing and product development. Ready to dive into 50 fascinating facts about this essential process? Let's get started!

Key Takeaways:

- Pigment dispersion ensures colors are vibrant and consistent in products like paint and cosmetics. It involves breaking down pigment particles and using specific techniques for even distribution.

- Industries like paint, ink, and cosmetics rely on pigment dispersion for quality and performance. Challenges like particle size and viscosity influence the process, but innovations like nanotechnology and advanced surfactants are improving efficiency.

What is Pigment Dispersion?

Pigment dispersion is a process where pigments are evenly distributed within a medium, like paint or ink. This ensures the color is consistent and vibrant. Let's dive into some fascinating facts about this process.

- Pigment dispersion involves breaking down pigment particles into smaller sizes.

- The process ensures pigments are evenly spread throughout the medium.

- Proper dispersion prevents clumping and streaking in the final product.

- Dispersing agents, or surfactants, help stabilize pigment particles.

- High-speed mixers and mills are often used to achieve fine dispersion.

- The quality of dispersion affects the color strength and brightness.

- Pigment dispersion is crucial in industries like paint, ink, and cosmetics.

- Water-based and solvent-based dispersions are two main types.

- Each type of pigment requires specific dispersion techniques.

- Poor dispersion can lead to issues like sedimentation and flocculation.

Importance of Pigment Dispersion in Different Industries

Pigment dispersion plays a vital role in various industries, ensuring products have the desired appearance and performance. Here are some key facts about its importance.

- In the paint industry, dispersion affects the paint's durability and finish.

- Ink manufacturers rely on dispersion for consistent print quality.

- Cosmetic products use well-dispersed pigments for smooth application.

- Textile printing requires even dispersion for vibrant fabric colors.

- Automotive coatings depend on dispersion for a flawless finish.

- Plastics use dispersed pigments for uniform color distribution.

- Pigment dispersion in ceramics ensures even color in glazes.

- The food industry uses dispersions for coloring edible products.

- Dispersed pigments in pharmaceuticals ensure accurate dosing.

- Pigment dispersion in construction materials enhances aesthetic appeal.

Techniques and Equipment Used in Pigment Dispersion

Various techniques and equipment are employed to achieve optimal pigment dispersion. These methods ensure pigments are finely and evenly distributed.

- Ball mills grind pigments into fine particles.

- High-speed dispersers mix pigments at high velocities.

- Bead mills use tiny beads to break down pigment particles.

- Three-roll mills apply shear force to disperse pigments.

- Ultrasonic homogenizers use sound waves for dispersion.

- Jet mills use high-velocity air to pulverize pigments.

- Attritors combine milling and mixing for efficient dispersion.

- High-pressure homogenizers force pigments through small orifices.

- Colloid mills use rotor-stator systems for fine dispersion.

- Continuous mixers provide consistent dispersion in large batches.

Challenges in Pigment Dispersion

Achieving perfect pigment dispersion can be challenging due to various factors. Understanding these challenges helps in improving the process.

- Pigment particle size affects dispersion quality.

- Agglomeration can occur if particles are not properly separated.

- Viscosity of the medium influences dispersion efficiency.

- Temperature changes can impact dispersion stability.

- pH levels affect the interaction between pigments and dispersing agents.

- Incompatible pigments can lead to poor dispersion.

- High shear forces may damage sensitive pigments.

- Air entrapment during mixing can cause defects.

- Contamination from equipment can alter dispersion quality.

- Achieving consistent dispersion in large batches is difficult.

Innovations in Pigment Dispersion

Recent advancements have led to improved techniques and materials for pigment dispersion. These innovations enhance the quality and efficiency of the process.

- Nanotechnology enables ultra-fine pigment dispersion.

- Advanced surfactants provide better stabilization.

- Automated systems ensure precise control over dispersion parameters.

- Eco-friendly dispersing agents reduce environmental impact.

- Real-time monitoring tools track dispersion progress.

- Hybrid dispersion techniques combine multiple methods for better results.

- Improved milling equipment offers higher efficiency.

- Computational modeling predicts optimal dispersion conditions.

- Sustainable pigments reduce the need for harmful chemicals.

- Continuous research drives innovation in pigment dispersion technology.

The Final Brushstroke

Pigment dispersion is more than just mixing colors. It’s a fascinating process that combines science, art, and technology. From the role of dispersants to the importance of particle size, every detail matters. Proper dispersion ensures vibrant, long-lasting colors in everything from paints to cosmetics. Without it, products could suffer from poor color quality and stability.

Understanding these facts can help anyone working with pigments achieve better results. Whether you’re a chemist, artist, or manufacturer, knowing the ins and outs of pigment dispersion can make a huge difference. So next time you see a beautifully colored product, remember the complex process behind it.

Pigment dispersion might seem like a small part of the production process, but its impact is huge. Keep these facts in mind, and you’ll appreciate the vibrant world of colors even more.

Frequently Asked Questions

Was this page helpful?

Our commitment to delivering trustworthy and engaging content is at the heart of what we do. Each fact on our site is contributed by real users like you, bringing a wealth of diverse insights and information. To ensure the highest standards of accuracy and reliability, our dedicated editors meticulously review each submission. This process guarantees that the facts we share are not only fascinating but also credible. Trust in our commitment to quality and authenticity as you explore and learn with us.