Spring steel is a type of steel known for its ability to return to its original shape after being bent or twisted. This unique property makes it incredibly useful in various applications, from automotive parts to industrial machinery. But what exactly makes spring steel so special? Its high yield strength and elasticity are key factors. These characteristics allow it to absorb energy and withstand significant stress without permanent deformation. Whether you're a DIY enthusiast, an engineer, or just curious about materials, understanding the properties and uses of spring steel can be both fascinating and practical. Ready to learn more? Let's dive into 50 intriguing facts about this versatile material!

Key Takeaways:

- Spring steel is a strong and flexible material used in making things like car parts, tools, and even musical instruments. It can withstand a lot of stress and return to its original shape after bending.

- While spring steel has many benefits, it can be tricky to work with and has an impact on the environment. Scientists are always trying to make it even better and more eco-friendly for the future.

What is Spring Steel?

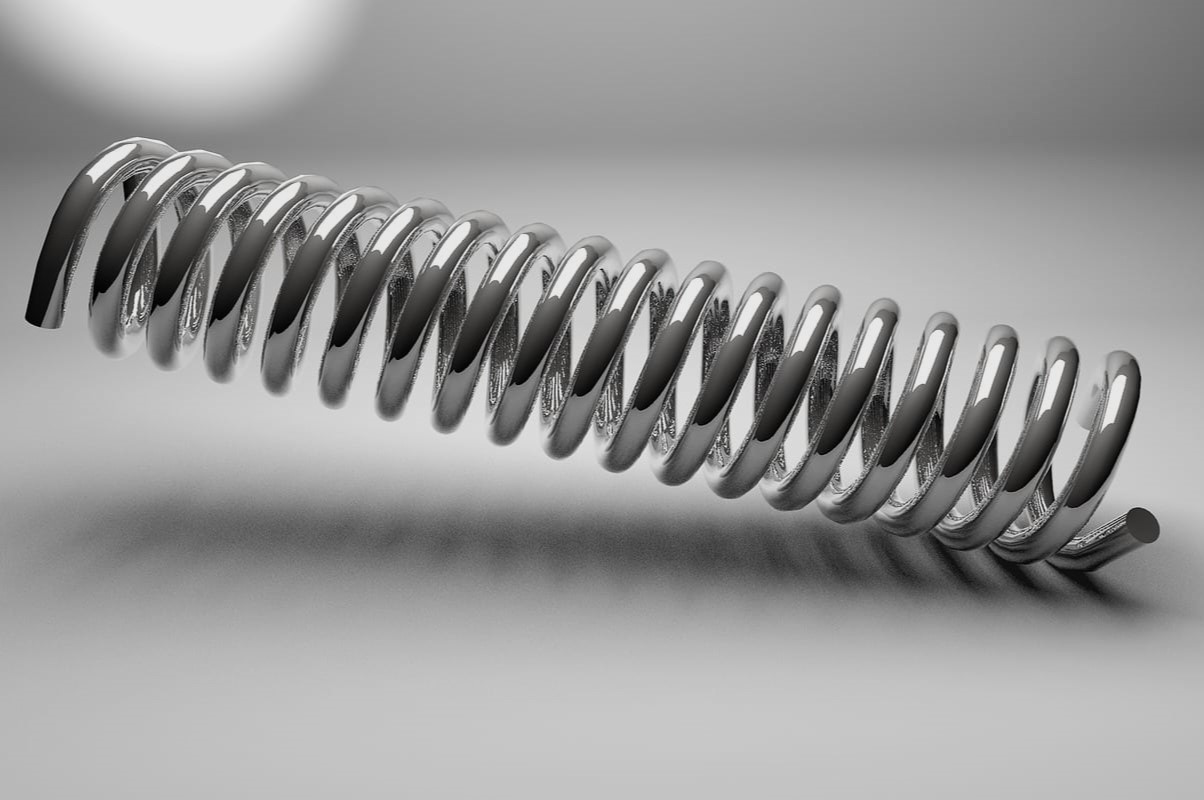

Spring steel is a versatile material known for its high yield strength and ability to return to its original shape after deformation. It's used in various applications, from automotive parts to industrial machinery.

- Spring steel is an alloy of iron and carbon, often with added silicon, manganese, or chromium to enhance its properties.

- This type of steel is known for its excellent elasticity, allowing it to bend and flex without permanent deformation.

- It is commonly used in the manufacturing of springs, hence the name "spring steel."

- The material can withstand significant stress and strain, making it ideal for high-stress applications.

- Spring steel is often used in the production of saw blades, due to its ability to maintain sharpness and resist wear.

Types of Spring Steel

There are several types of spring steel, each with unique properties suited for different applications.

- 1075 spring steel is a high-carbon steel known for its toughness and ability to hold a sharp edge.

- 1095 spring steel has a higher carbon content than 1075, making it harder and more wear-resistant.

- 5160 spring steel contains chromium, which improves its hardenability and corrosion resistance.

- 9260 spring steel includes silicon, providing excellent fatigue resistance and flexibility.

- EN47 spring steel is a silicon-manganese alloy known for its high tensile strength and toughness.

Applications of Spring Steel

Spring steel's unique properties make it suitable for a wide range of applications.

- Automotive industry uses spring steel for suspension springs, ensuring a smooth ride and vehicle stability.

- In the aerospace sector, it is used for landing gear and other critical components requiring high strength and flexibility.

- Spring steel is essential in the production of hand tools like pliers and wrenches, offering durability and resilience.

- It is also used in the manufacturing of musical instruments, such as piano wires and guitar strings.

- Industrial machinery often incorporates spring steel in components like clutches and couplings for its reliability under stress.

Heat Treatment of Spring Steel

Heat treatment processes are crucial for enhancing the properties of spring steel.

- Annealing involves heating the steel to a specific temperature and then cooling it slowly to soften the material and improve its machinability.

- Quenching is a process where the steel is heated to a high temperature and then rapidly cooled in water or oil to increase its hardness.

- Tempering follows quenching and involves reheating the steel to a lower temperature, then cooling it again to reduce brittleness while maintaining hardness.

- Normalizing is a heat treatment process that refines the grain structure of the steel, improving its toughness and strength.

- Stress relieving is a process that reduces residual stresses in the steel, enhancing its dimensional stability and performance.

Advantages of Spring Steel

Spring steel offers several benefits that make it a preferred material in various industries.

- High yield strength allows spring steel to withstand significant stress without permanent deformation.

- Excellent fatigue resistance ensures long-lasting performance in cyclic loading applications.

- Good wear resistance makes spring steel ideal for components exposed to friction and abrasion.

- The material's ability to return to its original shape after deformation provides reliability in dynamic applications.

- Spring steel's versatility allows it to be used in a wide range of industries, from automotive to aerospace.

Challenges in Working with Spring Steel

Despite its advantages, working with spring steel presents some challenges.

- High hardness can make machining and forming spring steel difficult, requiring specialized tools and techniques.

- The material's brittleness after quenching necessitates careful handling to avoid cracking or breaking.

- Spring steel's high carbon content can make it prone to rust, requiring protective coatings or treatments.

- Welding spring steel can be challenging due to its high carbon content, which can lead to cracking and weakening of the weld.

- Precise heat treatment is crucial to achieving the desired properties, requiring careful control of temperature and cooling rates.

Environmental Impact of Spring Steel

Like all materials, spring steel has an environmental impact that must be considered.

- The production of spring steel involves mining and processing raw materials, which can have significant environmental consequences.

- Energy-intensive processes like heat treatment contribute to the carbon footprint of spring steel production.

- Recycling spring steel can help mitigate its environmental impact, as the material can be melted down and reused.

- Advances in manufacturing technologies aim to reduce the environmental footprint of spring steel production.

- Sustainable practices in the steel industry, such as using renewable energy sources, can help minimize the environmental impact of spring steel.

Innovations in Spring Steel

Ongoing research and development continue to improve the properties and applications of spring steel.

- New alloy compositions are being developed to enhance the strength, flexibility, and corrosion resistance of spring steel.

- Advanced heat treatment techniques aim to optimize the material's properties while reducing energy consumption.

- Coating technologies are being explored to improve the wear and corrosion resistance of spring steel components.

- Additive manufacturing, or 3D printing, is being investigated for producing complex spring steel parts with reduced material waste.

- Smart materials incorporating spring steel are being developed for applications in robotics and other advanced technologies.

Historical Significance of Spring Steel

Spring steel has played a crucial role in the development of various technologies throughout history.

- The use of spring steel dates back to ancient times when blacksmiths used it to create durable tools and weapons.

- During the Industrial Revolution, spring steel was essential in the development of machinery and transportation systems.

- The material's properties made it a key component in the early automotive and aerospace industries.

- Spring steel has been used in the production of musical instruments for centuries, contributing to the evolution of music.

- The development of modern spring steel alloys has enabled advancements in technology and engineering.

Future of Spring Steel

The future of spring steel looks promising, with ongoing advancements and new applications on the horizon.

- Research into new alloy compositions will continue to improve the material's properties and performance.

- Sustainable manufacturing practices will help reduce the environmental impact of spring steel production.

- Innovations in coating and surface treatment technologies will enhance the durability and lifespan of spring steel components.

- The integration of spring steel into smart materials and advanced technologies will open up new possibilities for its use.

- As industries evolve, the demand for high-performance materials like spring steel will drive further advancements and applications.

The Final Word on Spring Steel

Spring steel stands out for its versatility and strength. Used in everything from automotive parts to swords, this material's unique properties make it indispensable. Its ability to return to its original shape after bending or twisting is what sets it apart.

Whether you're a DIY enthusiast or a professional engineer, understanding the benefits of spring steel can help you choose the right material for your projects. Its durability and resilience ensure long-lasting performance, saving both time and money in the long run.

So next time you encounter a product that needs to withstand stress and strain, consider spring steel. Its reliability and flexibility make it a top choice for countless applications. Keep these facts in mind, and you'll appreciate the incredible utility of this remarkable material.

Frequently Asked Questions

Was this page helpful?

Our commitment to delivering trustworthy and engaging content is at the heart of what we do. Each fact on our site is contributed by real users like you, bringing a wealth of diverse insights and information. To ensure the highest standards of accuracy and reliability, our dedicated editors meticulously review each submission. This process guarantees that the facts we share are not only fascinating but also credible. Trust in our commitment to quality and authenticity as you explore and learn with us.