Ever wondered how parts stay together without screws or glue? That's where interference fit comes into play. This method uses friction between two parts to hold them together tightly. Imagine a peg fitting so snugly into a hole that it won't budge. This technique is crucial in many industries, from automotive to aerospace. It ensures parts stay aligned and secure under stress. Curious about how it works, its benefits, and where it's used? You're in the right place. Let's dive into 40 fascinating facts about interference fit that will make you see machinery in a whole new light.

What is Interference Fit?

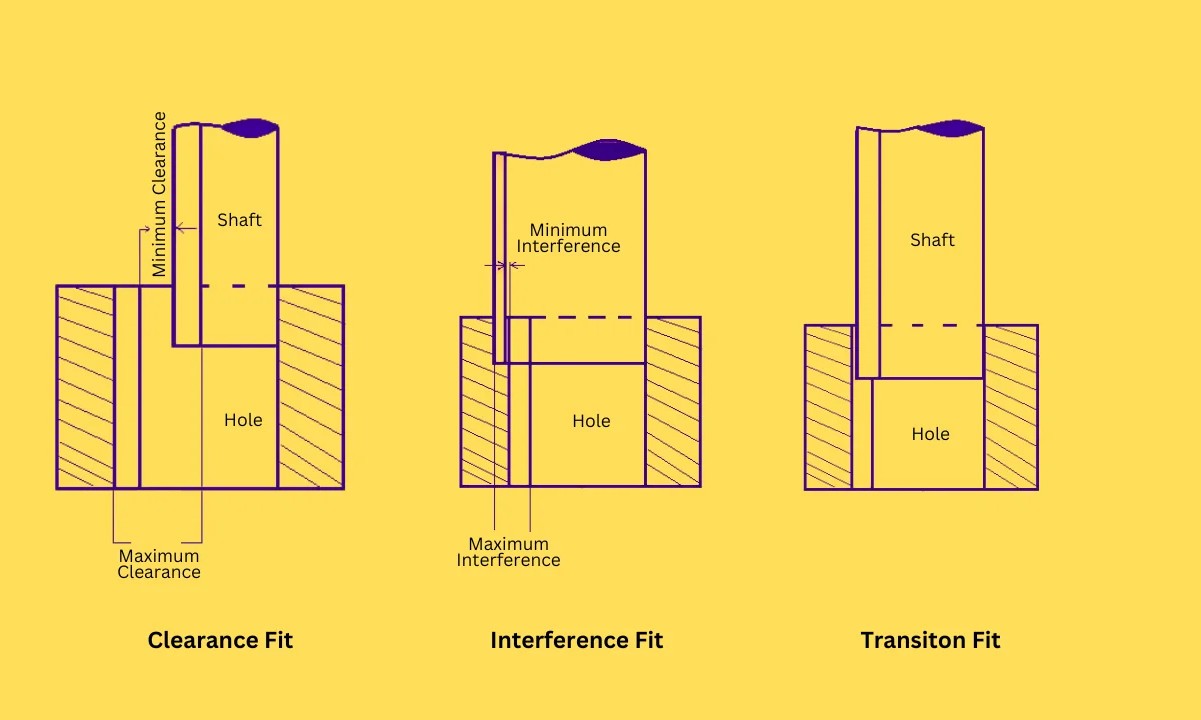

Interference fit, also known as a press fit or friction fit, is a fastening between two parts achieved by friction after the parts are pushed together. This method is commonly used in engineering and manufacturing to join components without the need for adhesives or welding.

- Interference fit relies on the principle of creating a tight fit between two parts, where the outer part is slightly larger than the inner part.

- This method is often used in applications where a strong, permanent bond is required.

- Common examples include gears, bearings, and bushings.

How Does Interference Fit Work?

Understanding the mechanics behind interference fit can help appreciate its importance in various applications.

- When two parts are pressed together, the material of the inner part deforms slightly to accommodate the outer part.

- This deformation creates a high frictional force that holds the parts together.

- The amount of interference, or the difference in size between the parts, determines the strength of the fit.

- Temperature changes can affect the fit, as materials expand and contract with heat.

Types of Interference Fit

Different types of interference fits are used depending on the application and required strength.

- Light Interference Fit: Used for applications requiring easy assembly and disassembly.

- Medium Interference Fit: Provides a balance between ease of assembly and holding strength.

- Heavy Interference Fit: Used for permanent assemblies where maximum strength is needed.

Applications of Interference Fit

Interference fit is widely used in various industries due to its reliability and strength.

- Automotive Industry: Used in assembling engine components like pistons and crankshafts.

- Aerospace Industry: Ensures the integrity of critical components like turbine blades.

- Manufacturing: Common in machinery where parts must withstand high stress and load.

- Electronics: Used in connectors and other components requiring precise alignment.

Advantages of Interference Fit

There are several benefits to using interference fit in engineering and manufacturing.

- Strong Bond: Provides a robust and reliable connection between parts.

- No Need for Adhesives: Eliminates the need for glue or welding, reducing costs and complexity.

- Durability: Offers long-lasting performance even under high stress.

- Precision: Ensures accurate alignment of components.

Challenges of Interference Fit

Despite its advantages, interference fit also presents some challenges.

- Assembly Difficulty: Requires precise machining and sometimes specialized equipment.

- Temperature Sensitivity: Changes in temperature can affect the fit, potentially leading to failure.

- Material Compatibility: Not all materials are suitable for interference fit, limiting its use in some applications.

- Disassembly: Removing parts joined by interference fit can be difficult and may damage the components.

Calculating Interference Fit

Proper calculation is crucial for achieving the desired strength and reliability.

- Interference Amount: Determined by the difference in size between the inner and outer parts.

- Material Properties: Factors like elasticity and thermal expansion must be considered.

- Load Requirements: The fit must withstand the expected load without failure.

- Tolerance Levels: Precise tolerances are necessary to ensure a proper fit.

Tools and Techniques for Achieving Interference Fit

Various tools and techniques are used to achieve a successful interference fit.

- Presses: Hydraulic or mechanical presses are commonly used to assemble parts.

- Heating and Cooling: Thermal expansion and contraction can aid in assembly.

- Lubricants: Reduce friction during assembly, making the process easier.

- Measurement Tools: Precision instruments ensure the correct size and fit.

Real-World Examples of Interference Fit

Interference fit is used in many real-world applications, demonstrating its versatility and reliability.

- Railway Wheels: Wheels are often fitted to axles using interference fit for a secure connection.

- Wind Turbines: Critical components are joined using interference fit to withstand high stress.

- Medical Devices: Ensures the integrity of implants and other critical components.

- Construction Equipment: Used in heavy machinery where durability is essential.

Innovations in Interference Fit

Advancements in technology continue to improve the effectiveness and application of interference fit.

- 3D Printing: Allows for precise control over dimensions, enhancing the accuracy of interference fits.

- Advanced Materials: New materials with better properties expand the possibilities for interference fit.

- Simulation Software: Helps engineers design and test interference fits before manufacturing.

- Automated Assembly: Robotics and automation streamline the assembly process, reducing errors.

Future of Interference Fit

The future of interference fit looks promising with ongoing research and development.

- Sustainability: Focus on eco-friendly materials and processes will drive innovation.

- Integration with IoT: Smart sensors and connected devices will enhance monitoring and maintenance of interference fits.

Final Thoughts on Interference Fit

Interference fit, also known as a press fit or friction fit, is a crucial technique in engineering and manufacturing. It ensures parts stay securely together without needing adhesives or fasteners. This method relies on the precise sizing of components, where one part is slightly larger than the other, creating a tight bond when assembled.

Understanding the principles behind interference fit can help in designing more reliable and durable products. It’s widely used in applications like gears, bearings, and bushings, where maintaining alignment and stability is essential.

By mastering this technique, engineers can achieve stronger connections, reduce wear and tear, and extend the lifespan of mechanical assemblies. Whether you’re working on a small project or a large-scale industrial application, knowing how to properly implement interference fit can make a significant difference in the performance and longevity of your designs.

Was this page helpful?

Our commitment to delivering trustworthy and engaging content is at the heart of what we do. Each fact on our site is contributed by real users like you, bringing a wealth of diverse insights and information. To ensure the highest standards of accuracy and reliability, our dedicated editors meticulously review each submission. This process guarantees that the facts we share are not only fascinating but also credible. Trust in our commitment to quality and authenticity as you explore and learn with us.