Eddy current testing is a non-destructive method used to detect flaws in conductive materials. But what makes it so special? Eddy currents are loops of electrical current induced within conductors by a changing magnetic field. This technique can identify cracks, corrosion, and other defects without damaging the material. It's widely used in industries like aerospace, automotive, and manufacturing. Eddy current testing is valued for its accuracy, speed, and ability to inspect complex shapes. Curious about how it works and its applications? Let's dive into 40 fascinating facts that will give you a deeper understanding of this essential testing method.

What is Eddy Current Testing?

Eddy current testing (ECT) is a non-destructive testing (NDT) method used to detect surface and sub-surface flaws in conductive materials. This technique relies on electromagnetic induction to identify defects. Here are some fascinating facts about ECT.

-

Invented in the 19th Century: ECT was first discovered by Michael Faraday in 1831 when he observed electromagnetic induction.

-

Named After Eddy Currents: The technique is named after the circular electric currents, known as eddy currents, which are induced within conductors by a changing magnetic field.

-

Used in Various Industries: ECT is widely used in aerospace, automotive, and manufacturing industries for quality control and maintenance.

-

Detects Cracks and Corrosion: This method is effective in identifying cracks, corrosion, and other surface defects in metals.

-

No Contact Needed: ECT can be performed without direct contact with the material, making it ideal for inspecting delicate or hard-to-reach areas.

-

Works on Conductive Materials: ECT is only applicable to conductive materials like metals. It cannot be used on non-conductive materials like plastics or ceramics.

-

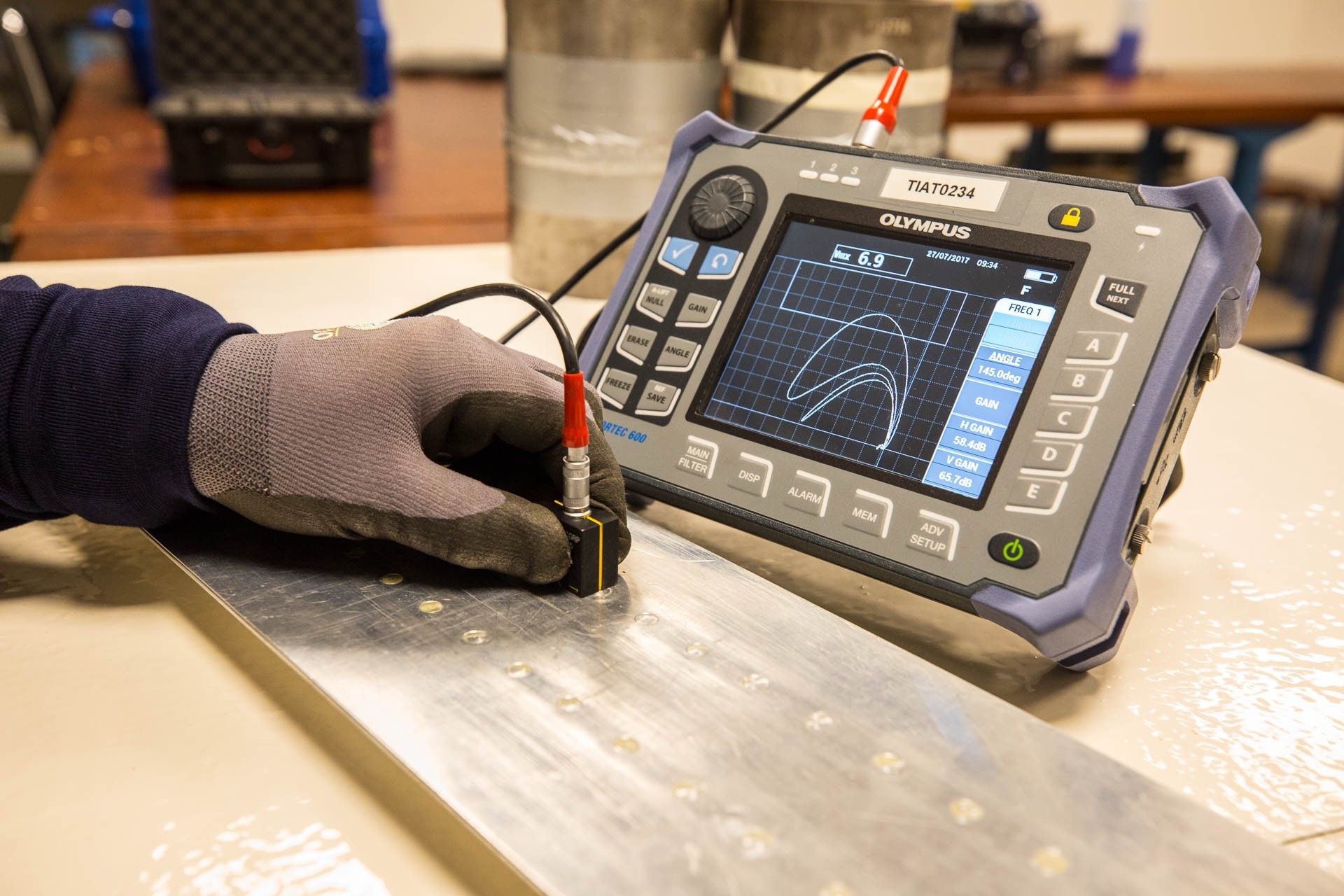

Portable Equipment: Modern ECT equipment is portable, allowing for on-site inspections in various environments.

-

High Sensitivity: ECT is highly sensitive and can detect very small defects that might be missed by other NDT methods.

-

Real-Time Results: This technique provides immediate results, enabling quick decision-making during inspections.

-

Used in Tube Inspections: ECT is commonly used to inspect heat exchanger tubes in power plants and refineries.

How Does Eddy Current Testing Work?

Understanding the working principle of ECT can shed light on its effectiveness and applications. Here’s a breakdown of how it operates.

-

Electromagnetic Induction: ECT works by inducing eddy currents in the material using an alternating magnetic field.

-

Probe Movement: A probe containing a coil is moved over the surface of the material to detect changes in the eddy currents.

-

Signal Interpretation: Variations in the eddy currents are detected by the probe and interpreted as signals, which indicate the presence of defects.

-

Frequency Matters: The frequency of the alternating current affects the depth of penetration of the eddy currents. Higher frequencies are used for surface inspections, while lower frequencies penetrate deeper.

-

Calibration is Key: Proper calibration of the ECT equipment is crucial for accurate defect detection.

-

Phase and Amplitude Analysis: The phase and amplitude of the eddy current signals are analyzed to determine the size and location of defects.

-

Lift-Off Effect: The distance between the probe and the material, known as lift-off, can affect the accuracy of the inspection. Minimizing lift-off is important for precise measurements.

-

Skin Effect: Eddy currents tend to flow near the surface of the material, a phenomenon known as the skin effect, which is utilized in surface inspections.

-

Multiple Coil Configurations: ECT probes can have different coil configurations, such as absolute, differential, or reflection, each suited for specific inspection needs.

-

Data Logging: Modern ECT devices can log data for further analysis and record-keeping.

Applications of Eddy Current Testing

ECT has a wide range of applications across different fields. Here are some notable uses.

-

Aircraft Maintenance: ECT is used to inspect aircraft components for cracks and corrosion, ensuring safety and reliability.

-

Railway Inspections: Rail tracks and wheels are inspected using ECT to detect wear and tear, preventing accidents.

-

Pipeline Monitoring: ECT helps in monitoring the integrity of pipelines, detecting corrosion and other defects.

-

Weld Inspections: Welds in structures and machinery are inspected using ECT to ensure they are free from defects.

-

Quality Control in Manufacturing: ECT is used in manufacturing to ensure the quality of metal parts and components.

-

Nuclear Industry: ECT is employed in the nuclear industry to inspect reactor components and ensure their integrity.

-

Marine Industry: Ships and offshore structures are inspected using ECT to detect corrosion and other defects.

-

Automotive Industry: Car manufacturers use ECT to inspect engine components and other critical parts.

-

Power Generation: ECT is used in power plants to inspect turbines, generators, and other equipment.

-

Art and Antiquities: ECT can be used to inspect metal artifacts and artworks for authenticity and condition assessment.

Advantages of Eddy Current Testing

ECT offers several benefits that make it a preferred choice for many applications. Here are some advantages.

-

Non-Destructive: ECT does not damage the material being inspected, preserving its integrity.

-

Quick and Efficient: Inspections can be performed quickly, saving time and reducing downtime.

-

Versatile: ECT can be used on a wide range of conductive materials and in various environments.

-

High Accuracy: The method provides accurate detection of defects, ensuring reliability.

-

Cost-Effective: ECT is a cost-effective solution for regular inspections and maintenance.

-

Minimal Preparation: Little to no surface preparation is required before inspection, making the process more efficient.

-

Safe: ECT is a safe method as it does not involve radiation or harmful chemicals.

-

Automated Inspections: ECT can be automated for large-scale inspections, increasing efficiency.

-

Environmental Impact: ECT has a low environmental impact as it does not produce waste or pollutants.

-

Adaptability: The technique can be adapted for different inspection needs, from surface to sub-surface defects.

The Power of Eddy Current Testing

Eddy current testing is a game-changer in the world of non-destructive testing. It’s efficient, accurate, and versatile. From detecting cracks in aircraft to ensuring the integrity of pipelines, this method has proven its worth. The ability to inspect without causing damage makes it invaluable across various industries. Plus, its quick results mean less downtime and more productivity.

Understanding the basics of eddy current testing can help you appreciate its importance. Whether you’re in manufacturing, aerospace, or even the energy sector, knowing how this technology works can give you an edge. It’s not just about finding flaws; it’s about ensuring safety and reliability.

So, next time you hear about eddy current testing, you’ll know it’s more than just a technical term. It’s a vital tool keeping our world running smoothly and safely.

Was this page helpful?

Our commitment to delivering trustworthy and engaging content is at the heart of what we do. Each fact on our site is contributed by real users like you, bringing a wealth of diverse insights and information. To ensure the highest standards of accuracy and reliability, our dedicated editors meticulously review each submission. This process guarantees that the facts we share are not only fascinating but also credible. Trust in our commitment to quality and authenticity as you explore and learn with us.