Siemens NX is a powerful software suite used for computer-aided design (CAD), manufacturing (CAM), and engineering (CAE). But what makes Siemens NX stand out? This tool offers a comprehensive range of features that streamline product development, from initial concept to final production. Did you know that Siemens NX integrates seamlessly with other Siemens software, enhancing collaboration and efficiency? Whether you're an engineer, designer, or manufacturer, understanding the capabilities of Siemens NX can significantly impact your workflow. Let's dive into 39 intriguing facts about Siemens NX that highlight its versatility, innovation, and user-friendly interface. Ready to learn how this software can transform your projects? Keep reading!

What is Siemens NX?

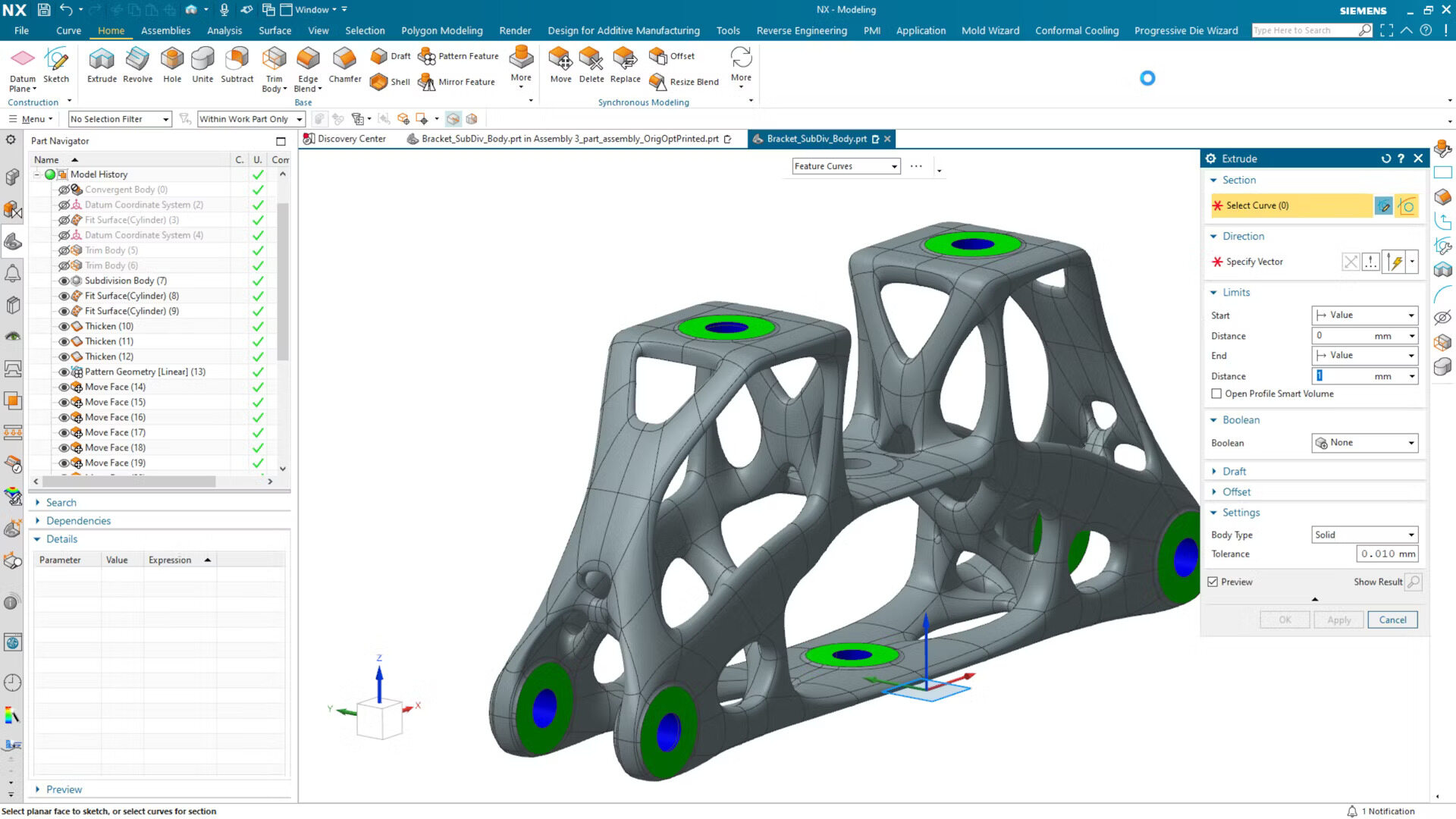

Siemens NX, also known as NX Unigraphics, is a powerful integrated solution for CAD, CAM, and CAE. It helps engineers and designers create, simulate, and manufacture products more efficiently. Here are some fascinating facts about Siemens NX:

- Siemens NX was originally developed by Unigraphics, which was later acquired by Siemens in 2007.

- The software is widely used in industries such as automotive, aerospace, and consumer goods.

- Siemens NX is known for its advanced modeling capabilities, including parametric and direct modeling.

- It supports a wide range of file formats, making it easy to integrate with other software tools.

- The software includes powerful simulation tools that help engineers test and validate their designs before manufacturing.

Key Features of Siemens NX

Siemens NX offers a plethora of features that make it a go-to solution for many engineers and designers. Let's dive into some of these key features:

- The software provides comprehensive CAD tools for creating detailed 3D models.

- It includes advanced CAM capabilities for generating toolpaths and optimizing machining processes.

- Siemens NX offers robust CAE tools for performing structural, thermal, and fluid simulations.

- The software supports collaborative design, allowing multiple users to work on the same project simultaneously.

- Siemens NX includes powerful rendering tools for creating high-quality visualizations of designs.

Benefits of Using Siemens NX

Using Siemens NX can bring numerous benefits to your design and manufacturing processes. Here are some of the key advantages:

- The software helps reduce design cycle times by streamlining workflows and automating repetitive tasks.

- Siemens NX improves product quality by enabling thorough testing and validation of designs.

- It enhances collaboration among team members, leading to more efficient and effective project management.

- The software supports digital twin technology, allowing for virtual testing and optimization of products.

- Siemens NX helps reduce manufacturing costs by optimizing toolpaths and machining processes.

Siemens NX in the Automotive Industry

The automotive industry is one of the primary users of Siemens NX. Let's explore how the software is utilized in this sector:

- Siemens NX is used for designing complex automotive components, such as engines and transmissions.

- The software helps engineers simulate crash tests and other safety scenarios to ensure vehicle safety.

- It supports the design and optimization of lightweight materials, which are crucial for improving fuel efficiency.

- Siemens NX enables the integration of electronic systems into automotive designs, supporting the development of smart vehicles.

- The software helps streamline the manufacturing process by optimizing toolpaths and reducing machining times.

Siemens NX in the Aerospace Industry

The aerospace industry also relies heavily on Siemens NX for designing and manufacturing aircraft components. Here are some ways the software is used in this sector:

- Siemens NX is used for designing complex aerospace components, such as wings and fuselages.

- The software helps engineers simulate aerodynamic performance and optimize designs for better fuel efficiency.

- It supports the integration of advanced materials, such as composites, into aerospace designs.

- Siemens NX enables the simulation of extreme conditions, such as high temperatures and pressures, to ensure the reliability of aerospace components.

- The software helps streamline the manufacturing process by optimizing toolpaths and reducing machining times.

Siemens NX in Consumer Goods

Siemens NX is also widely used in the consumer goods industry for designing and manufacturing a variety of products. Here are some examples:

- The software is used for designing household appliances, such as refrigerators and washing machines.

- Siemens NX helps engineers create ergonomic designs that improve user comfort and satisfaction.

- It supports the integration of electronic components into consumer products, enabling the development of smart devices.

- The software helps optimize the manufacturing process by reducing material waste and improving production efficiency.

- Siemens NX enables the creation of high-quality visualizations, which are useful for marketing and sales purposes.

Siemens NX and Digital Twins

Digital twin technology is a key feature of Siemens NX, allowing for virtual testing and optimization of products. Here are some facts about this technology:

- Digital twins are virtual replicas of physical products that can be used for testing and optimization.

- Siemens NX supports the creation of digital twins, enabling engineers to test designs in a virtual environment.

- Digital twins help reduce the need for physical prototypes, saving time and money.

- The technology allows for real-time monitoring and optimization of products throughout their lifecycle.

- Siemens NX integrates with other Siemens software tools, such as Teamcenter, to support digital twin technology.

Siemens NX and Additive Manufacturing

Additive manufacturing, also known as 3D printing, is another area where Siemens NX excels. Here are some facts about how the software supports this technology:

- Siemens NX includes tools for designing and optimizing parts for additive manufacturing.

- The software supports a wide range of 3D printing technologies, including FDM, SLS, and SLA.

- Siemens NX helps engineers create lightweight, complex geometries that are difficult to produce with traditional manufacturing methods.

- The software includes simulation tools for predicting the performance of 3D-printed parts.

Final Thoughts on Siemens NX

Siemens NX stands out as a powerful tool in the world of design and engineering. Its integrated solutions for CAD, CAM, and CAE streamline workflows, making it easier for professionals to bring their ideas to life. The advanced simulation capabilities help predict real-world performance, reducing the need for physical prototypes. Customization options allow users to tailor the software to their specific needs, enhancing productivity. The collaborative features ensure that teams can work together seamlessly, no matter where they are. With continuous updates and support, Siemens NX remains a top choice for industries ranging from automotive to aerospace. Whether you're a seasoned engineer or just starting out, this software offers the tools you need to succeed. Dive into Siemens NX and see how it can transform your projects.

Was this page helpful?

Our commitment to delivering trustworthy and engaging content is at the heart of what we do. Each fact on our site is contributed by real users like you, bringing a wealth of diverse insights and information. To ensure the highest standards of accuracy and reliability, our dedicated editors meticulously review each submission. This process guarantees that the facts we share are not only fascinating but also credible. Trust in our commitment to quality and authenticity as you explore and learn with us.