Mold design is a crucial aspect of manufacturing that impacts the quality and efficiency of production. But what exactly is mold design? In simple terms, it involves creating molds used to shape materials like plastic, metal, or glass into specific forms. These molds are essential for producing everything from car parts to kitchen utensils. Understanding mold design can save time, reduce costs, and improve product quality. This process requires precision, creativity, and a deep understanding of materials and machinery. Whether you're a student, a hobbyist, or a professional, knowing the basics of mold design can open up a world of possibilities in manufacturing.

What is Mold Design?

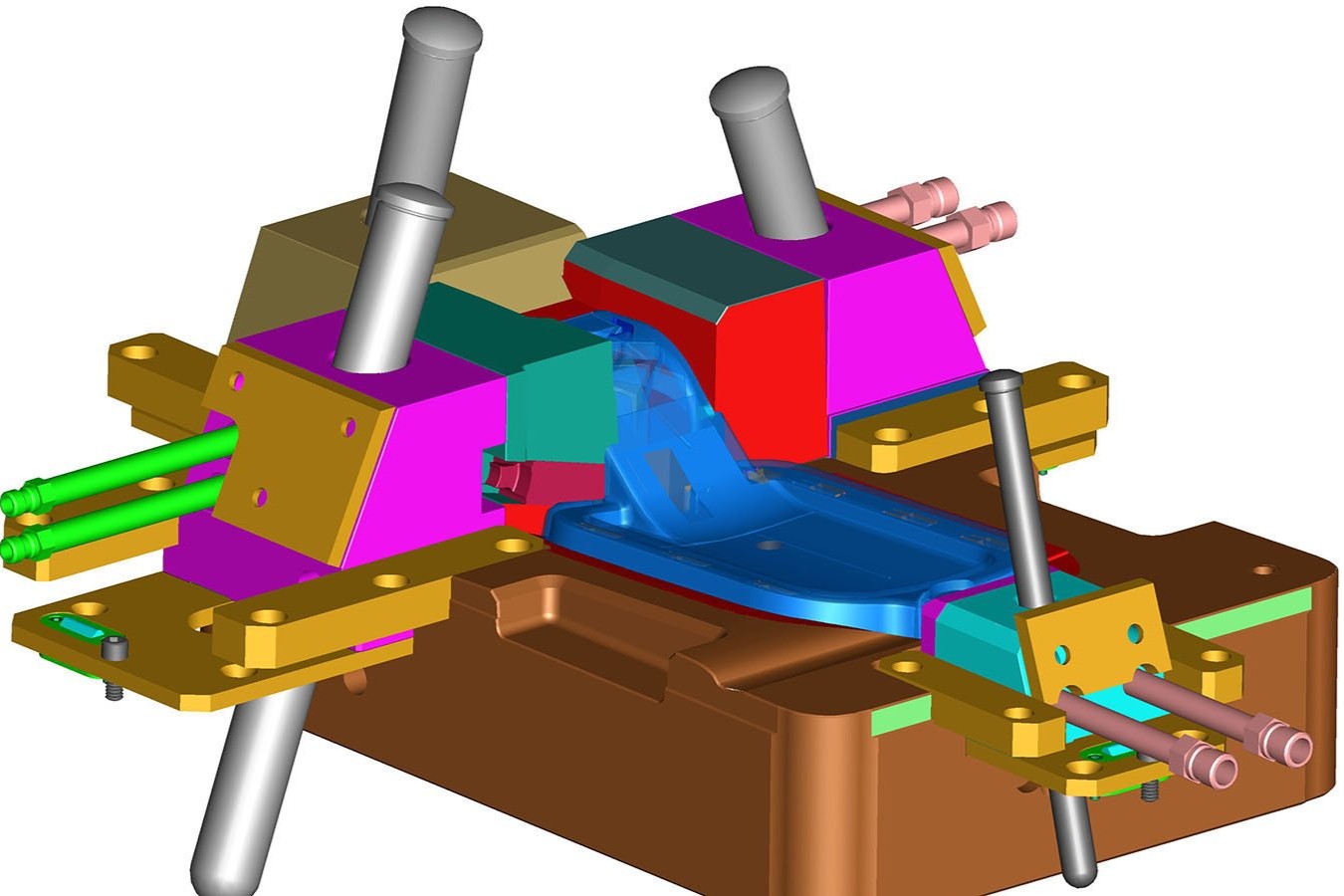

Mold design is a fascinating field that combines engineering, creativity, and precision. It involves creating molds used to shape materials like plastic, metal, or glass into specific forms. These molds are essential in manufacturing everything from car parts to toys.

- Mold design is crucial in the manufacturing process, ensuring products are made accurately and efficiently.

- The process involves creating a cavity in a mold where material is injected, cooled, and solidified.

- Mold designers use computer-aided design (CAD) software to create detailed blueprints.

- Precision is key in mold design; even a tiny error can lead to defective products.

- Mold design requires knowledge of materials science, engineering principles, and manufacturing processes.

History of Mold Design

The history of mold design dates back centuries, evolving significantly over time. Understanding its origins helps appreciate the advancements made in this field.

- Ancient civilizations used simple molds to create pottery and metal objects.

- The Industrial Revolution brought significant advancements in mold design, with the invention of new machinery.

- Injection molding, a popular method today, was developed in the late 19th century.

- Early molds were made from wood or clay, while modern molds use metals like steel and aluminum.

- The introduction of CAD software in the 1980s revolutionized mold design, allowing for more complex and precise designs.

Types of Molds

There are various types of molds, each serving a specific purpose in manufacturing. Knowing the different types helps understand their applications.

- Injection molds are used to produce plastic parts by injecting molten plastic into a mold cavity.

- Blow molds create hollow objects like bottles by inflating a heated plastic tube inside a mold.

- Compression molds shape materials by pressing them into a mold under heat and pressure.

- Transfer molds are similar to compression molds but involve transferring material from a chamber into the mold.

- Extrusion molds shape materials by forcing them through a die to create long, continuous shapes.

Materials Used in Mold Design

The choice of materials in mold design is critical, affecting the durability and performance of the mold. Different materials are used based on the specific requirements of the mold.

- Steel is commonly used for molds due to its strength and durability.

- Aluminum is another popular choice, offering a good balance between strength and weight.

- Beryllium copper is used for molds requiring excellent thermal conductivity.

- Silicone molds are flexible and used for casting materials like resin or plaster.

- Epoxy molds are lightweight and often used for prototyping.

The Mold Design Process

The mold design process involves several steps, from initial concept to final production. Each step is crucial to ensure the mold functions correctly.

- The process begins with a detailed design using CAD software.

- Prototyping is often done to test the design before full-scale production.

- Once the design is finalized, the mold is manufactured using techniques like CNC machining or 3D printing.

- After manufacturing, the mold undergoes testing to ensure it meets specifications.

- Maintenance is essential to keep molds in good condition and extend their lifespan.

Challenges in Mold Design

Mold design is not without its challenges. Designers must overcome various obstacles to create effective molds.

- Achieving precise tolerances can be difficult, requiring advanced machinery and techniques.

- Material selection is critical, as the wrong material can lead to mold failure.

- Designing molds for complex shapes requires creativity and problem-solving skills.

- Cost is always a factor, with high-quality molds often being expensive to produce.

- Keeping up with technological advancements is essential for staying competitive in the field.

Innovations in Mold Design

The field of mold design is constantly evolving, with new technologies and methods emerging regularly. These innovations help improve efficiency and product quality.

- 3D printing has revolutionized prototyping, allowing for faster and more cost-effective testing.

- Advanced CAD software offers more precise and complex design capabilities.

- Automation in mold manufacturing reduces human error and increases production speed.

- New materials, like high-performance polymers, offer better durability and performance.

- Simulation software allows designers to test molds virtually, identifying potential issues before production.

Fun Facts About Mold Design

Mold design might seem technical, but it has some interesting and fun aspects too. Here are a few tidbits that might surprise you.

- The LEGO company uses highly precise molds to ensure each brick fits perfectly with others.

- Some molds are so complex they can take months to design and manufacture.

Final Thoughts on Mold

Mold is more than just an annoying household issue. It can affect health, damage property, and even impact the environment. Knowing the facts about mold helps in preventing its growth and dealing with it effectively. Regular cleaning, proper ventilation, and moisture control are key to keeping mold at bay. If you spot mold, act quickly to remove it and address the underlying cause. Sometimes, professional help might be necessary, especially for large infestations. Remember, mold can be sneaky, hiding in places you might not expect. Stay vigilant and proactive to ensure a healthy living space. By understanding mold better, you can protect your home and loved ones from its harmful effects. Stay informed, stay safe, and keep your environment mold-free.

Was this page helpful?

Our commitment to delivering trustworthy and engaging content is at the heart of what we do. Each fact on our site is contributed by real users like you, bringing a wealth of diverse insights and information. To ensure the highest standards of accuracy and reliability, our dedicated editors meticulously review each submission. This process guarantees that the facts we share are not only fascinating but also credible. Trust in our commitment to quality and authenticity as you explore and learn with us.