Gear trains are fascinating mechanisms that play a crucial role in many machines and devices we use daily. From clocks to cars, these systems of interlocking gears help transfer motion and force efficiently. But what exactly makes gear trains so important? Gear trains allow for changes in speed and torque, enabling machines to perform tasks that would be impossible with a single gear. They also help in reducing wear and tear by distributing the load across multiple gears. Whether you're a budding engineer or just curious about how things work, understanding gear trains can give you a deeper appreciation for the technology that powers our world. Ready to learn some intriguing facts about these mechanical marvels? Let's get started!

What is a Gear Train?

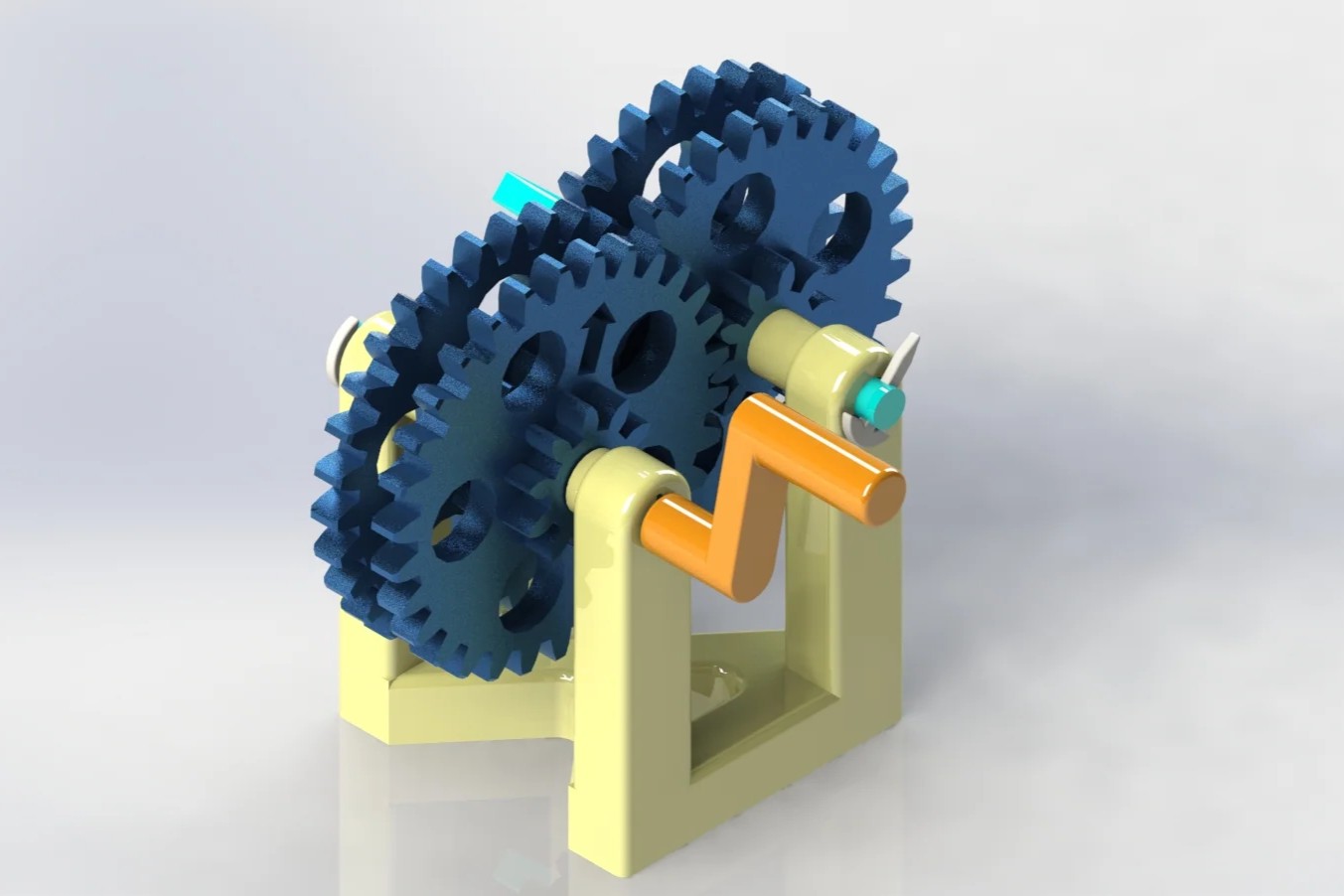

A gear train is a system of gears working together to transmit motion and force. These mechanical marvels are found in everything from watches to cars. Let's dive into some fascinating facts about gear trains.

-

Gears come in various shapes and sizes. They can be spur, helical, bevel, or worm gears, each designed for specific applications.

-

The simplest gear train consists of just two gears. When one gear turns, it causes the other to turn in the opposite direction.

-

Gear trains can increase or decrease speed. By changing the size of the gears, you can make a machine move faster or slower.

-

They can also change the direction of motion. For example, bevel gears can change the direction of motion by 90 degrees.

-

Gear trains are essential in clocks. They help keep accurate time by controlling the movement of the clock hands.

How Gear Trains Work

Understanding how gear trains work can be quite intriguing. They rely on the interaction between teeth on different gears to transmit motion and force.

-

The gear ratio is crucial. It’s the ratio of the number of teeth on one gear to the number of teeth on another. This ratio determines the mechanical advantage.

-

Mechanical advantage allows a small force to move a larger load. This is why gear trains are used in heavy machinery.

-

Compound gear trains involve multiple gears. They can achieve higher gear ratios and more complex motion.

-

Epicyclic gear trains have gears that rotate around other gears. These are used in automatic transmissions in cars.

-

Gear trains can be found in bicycles. The gears help cyclists adjust the difficulty of pedaling.

Applications of Gear Trains

Gear trains are everywhere, from everyday objects to complex machinery. Their versatility makes them indispensable.

-

Wristwatches use tiny gear trains. These help keep accurate time and power additional features like date displays.

-

Automobiles rely heavily on gear trains. They are found in the transmission, differential, and even the windshield wipers.

-

Wind turbines use gear trains. They convert the slow rotation of the blades into faster rotation to generate electricity.

-

Robots use gear trains. They help in precise movements and control of robotic arms.

-

Elevators depend on gear trains. They ensure smooth and controlled movement between floors.

Historical Significance of Gear Trains

Gear trains have been around for centuries, playing a crucial role in technological advancements.

-

The Antikythera mechanism is an ancient Greek device. It used a complex gear train to predict astronomical positions.

-

Leonardo da Vinci sketched gear trains. His designs included various gear mechanisms for different inventions.

-

The Industrial Revolution saw a boom in gear train usage. They powered machines in factories, leading to mass production.

-

Early automobiles used simple gear trains. These evolved into the complex transmissions we see today.

-

Mechanical clocks in medieval Europe used gear trains. They were essential for timekeeping in churches and towns.

Fun Facts About Gear Trains

Gear trains are not just functional; they can also be fascinating and fun to learn about.

-

Lego sets often include gear trains. They teach kids about mechanics and engineering.

-

Some musical instruments use gear trains. For example, pipe organs use them to control the flow of air.

-

Gear trains can be found in toys. Wind-up toys use them to store and release energy.

-

The world's largest gear is in a cement plant in China. It measures over 13 meters in diameter.

-

Gear trains can be made from various materials. Metals, plastics, and even wood can be used depending on the application.

Modern Innovations in Gear Trains

With advancements in technology, gear trains continue to evolve, becoming more efficient and versatile.

-

3D printing allows for custom gears. This technology enables rapid prototyping and production of complex gear trains.

-

Smart gear trains are being developed. These can adjust their operation based on real-time data.

-

Magnetic gears are an emerging technology. They use magnetic fields instead of physical teeth to transmit motion.

-

Nano-gears are being researched. These tiny gears could revolutionize medical devices and nanotechnology.

-

Self-lubricating gears reduce maintenance. They are made from materials that release lubricants during operation.

Challenges and Solutions in Gear Trains

Despite their many advantages, gear trains also face challenges. Engineers continually work on solutions to improve their performance.

-

Wear and tear is a common issue. Regular maintenance and using high-quality materials can mitigate this.

-

Noise reduction is important. Helical gears are often used because they operate more quietly than spur gears.

-

Heat generation can be problematic. Proper lubrication and cooling systems help manage this.

-

Precision manufacturing is crucial. Even small errors in gear teeth can lead to significant problems.

-

Efficiency improvements are ongoing. Engineers strive to make gear trains more efficient to save energy and reduce costs.

Final Gear Train Insights

Gear trains are everywhere, from watches to cars. They make complex tasks simpler by transferring motion and force efficiently. Understanding gear ratios helps in designing machines that work smoothly and effectively. Knowing the difference between simple, compound, and planetary gear trains can aid in choosing the right system for specific needs.

Maintenance is crucial. Regular checks and lubrication extend the life of gears, preventing costly breakdowns. Innovations in materials and design continue to push the boundaries of what gear trains can achieve, making them more durable and efficient.

Whether you're a hobbyist or a professional, grasping the basics of gear trains can enhance your projects. They might seem complex, but with a bit of study, anyone can appreciate their elegance and utility. Keep exploring, and you'll find gear trains are not just mechanical components but marvels of engineering.

Was this page helpful?

Our commitment to delivering trustworthy and engaging content is at the heart of what we do. Each fact on our site is contributed by real users like you, bringing a wealth of diverse insights and information. To ensure the highest standards of accuracy and reliability, our dedicated editors meticulously review each submission. This process guarantees that the facts we share are not only fascinating but also credible. Trust in our commitment to quality and authenticity as you explore and learn with us.