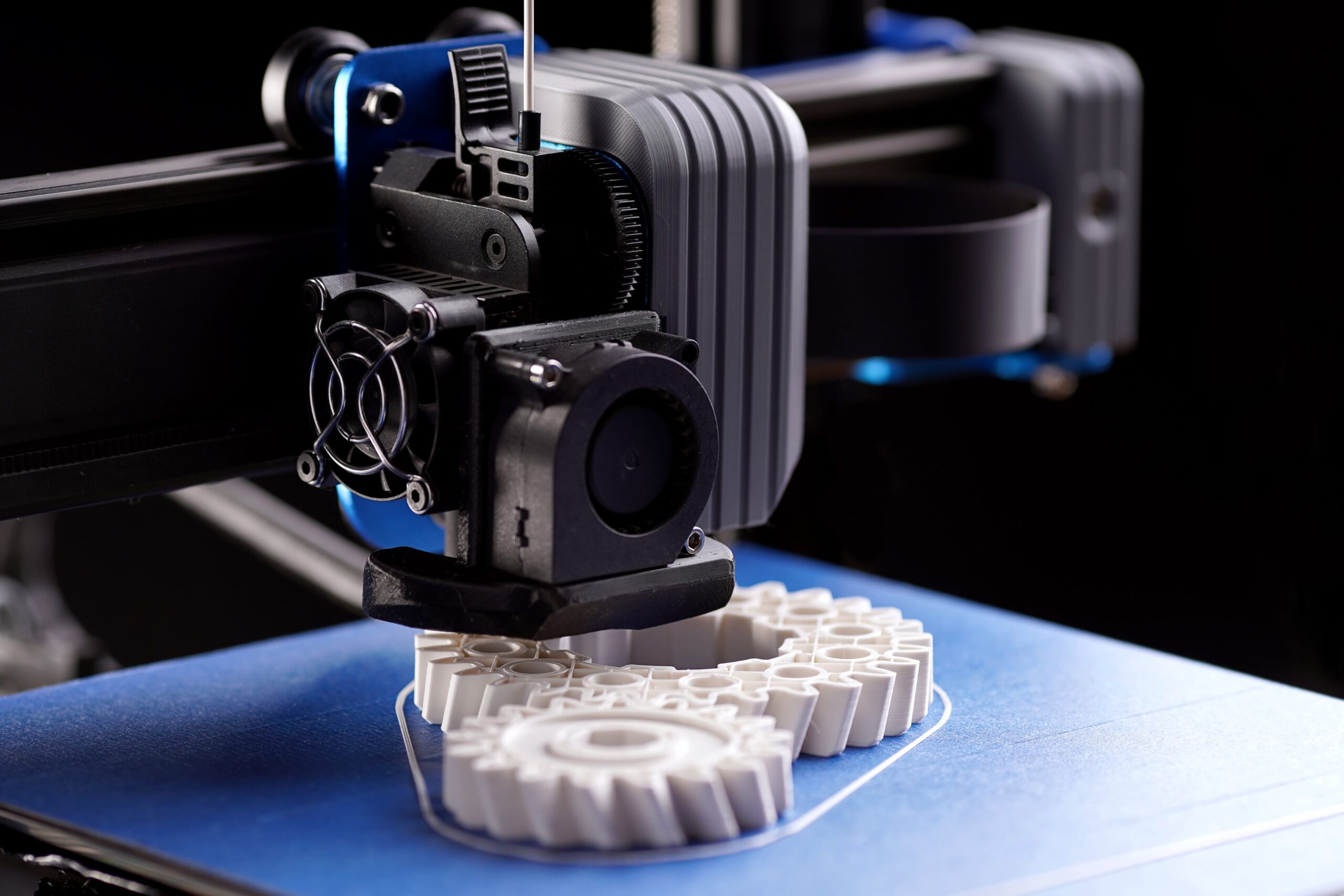

Fused Deposition Modeling (FDM) is a popular 3D printing technique that has revolutionized manufacturing and prototyping. But what exactly is FDM? In simple terms, FDM is a process where a thermoplastic filament is heated and extruded layer by layer to create a 3D object. This method is widely used due to its affordability, ease of use, and versatility. Whether you're a hobbyist or a professional, understanding the ins and outs of FDM can open up a world of possibilities. From creating intricate designs to producing functional parts, FDM offers a range of applications that make it a go-to choice for many. Ready to dive into the fascinating world of FDM? Let's get started!

What is Fused Deposition Modeling?

Fused Deposition Modeling (FDM) is a popular 3D printing technology. It creates objects layer by layer using thermoplastic materials. Here are some fascinating facts about FDM that highlight its significance and versatility.

-

FDM was invented by Scott Crump in 1988. He co-founded Stratasys, a leading 3D printing company.

-

The process involves heating a thermoplastic filament until it melts, then extruding it through a nozzle to build an object layer by layer.

-

FDM is also known as Fused Filament Fabrication (FFF). Both terms describe the same technology.

-

Common materials used in FDM include ABS, PLA, PETG, and TPU. Each material has unique properties suitable for different applications.

-

FDM printers are widely used in prototyping. They allow designers to quickly create and test models before mass production.

How FDM Works

Understanding the mechanics behind FDM can help appreciate its capabilities. Here's a closer look at the process.

-

The printer's nozzle moves along the X and Y axes to create each layer's shape. The build platform moves along the Z axis to stack layers.

-

A heated build platform helps prevent warping by keeping the printed object warm during the process.

-

The nozzle's diameter affects the print's resolution. Smaller nozzles produce finer details but take longer to print.

-

FDM printers can have single or multiple extruders. Multiple extruders allow for printing with different materials or colors simultaneously.

-

Support structures are often needed for overhanging parts. These structures are removed after printing.

Advantages of FDM

FDM offers several benefits that make it a popular choice for various applications. Here are some key advantages.

-

FDM printers are relatively affordable compared to other 3D printing technologies. This makes them accessible to hobbyists and small businesses.

-

The technology is user-friendly. Many FDM printers come with intuitive software and easy setup processes.

-

FDM allows for the use of a wide range of materials. This versatility makes it suitable for different industries, from automotive to healthcare.

-

The process is environmentally friendly. Many FDM materials are biodegradable or recyclable.

-

FDM prints are durable and can withstand mechanical stress. This makes them ideal for functional prototypes and end-use parts.

Applications of FDM

FDM's versatility extends to various fields. Here are some notable applications.

-

In the medical field, FDM is used to create custom prosthetics and surgical guides. These personalized devices improve patient outcomes.

-

The automotive industry uses FDM for rapid prototyping and producing custom parts. This speeds up the design and testing phases.

-

FDM is popular in education. Schools and universities use it to teach students about engineering, design, and manufacturing.

-

Artists and designers use FDM to create intricate sculptures and models. The technology allows for high levels of detail and customization.

-

Aerospace companies use FDM to produce lightweight, complex parts. This helps reduce the weight and cost of aircraft.

Challenges of FDM

Despite its advantages, FDM has some limitations. Understanding these challenges can help users make informed decisions.

-

FDM prints can have visible layer lines. Post-processing techniques like sanding and painting are often needed to achieve a smooth finish.

-

Warping and cracking can occur, especially with larger prints. Proper bed adhesion and temperature control are crucial to minimize these issues.

-

The printing speed of FDM is relatively slow compared to other 3D printing technologies. This can be a drawback for large-scale production.

-

FDM printers require regular maintenance. Cleaning the nozzle and ensuring proper calibration are essential for consistent print quality.

-

Some materials used in FDM can emit fumes when heated. Proper ventilation is necessary to ensure a safe working environment.

Innovations in FDM

The field of FDM is constantly evolving. Here are some recent innovations that are pushing the boundaries of this technology.

-

Multi-material printing allows for the creation of complex objects with different properties. This opens up new possibilities for functional prototypes.

-

Advanced software algorithms improve print quality by optimizing layer paths and reducing print time.

-

High-temperature FDM printers can print with engineering-grade materials like PEEK and Ultem. These materials offer superior strength and heat resistance.

-

Flexible filaments like TPU enable the creation of soft, rubber-like objects. This is useful for applications requiring flexibility and durability.

-

Large-format FDM printers can produce objects several meters in size. This is beneficial for industries like construction and architecture.

Future of FDM

The future of FDM looks promising with ongoing research and development. Here are some trends to watch.

-

Integration with other technologies like AI and IoT will enhance the capabilities of FDM printers. Smart printers can optimize print settings and predict maintenance needs.

-

The development of new materials will expand the range of applications. Biodegradable and conductive filaments are just a few examples.

-

Hybrid manufacturing combines FDM with traditional methods like CNC machining. This allows for the creation of complex parts with high precision.

-

Increased automation will make FDM more efficient. Automated print farms can produce large quantities of parts with minimal human intervention.

-

The growing maker movement will continue to drive innovation in FDM. Community-driven projects and open-source designs will push the boundaries of what's possible.

The Final Layer

Fused deposition modeling (FDM) has revolutionized how we create and innovate. From prototyping to manufacturing, FDM offers a versatile and cost-effective solution. Its ability to produce complex geometries with various materials makes it a go-to choice for many industries.

Understanding the facts about FDM helps appreciate its impact on technology and everyday life. Whether you're a hobbyist or a professional, knowing these details can enhance your projects and spark new ideas.

FDM's journey from a niche technology to a mainstream tool showcases its potential and adaptability. As we continue to explore its capabilities, the possibilities seem endless. So, next time you see a 3D-printed object, remember the fascinating process behind it.

Embrace the future of manufacturing with FDM, and let your creativity soar.

Was this page helpful?

Our commitment to delivering trustworthy and engaging content is at the heart of what we do. Each fact on our site is contributed by real users like you, bringing a wealth of diverse insights and information. To ensure the highest standards of accuracy and reliability, our dedicated editors meticulously review each submission. This process guarantees that the facts we share are not only fascinating but also credible. Trust in our commitment to quality and authenticity as you explore and learn with us.