Conformal cooling is a game-changer in the world of manufacturing, especially in injection molding. But what exactly is it? Conformal cooling involves creating cooling channels that follow the shape of the mold, unlike traditional straight-line channels. This technique allows for more efficient heat removal, leading to faster cycle times and improved part quality. Imagine producing complex parts with fewer defects and shorter production times. Sounds impressive, right? In this article, we'll dive into 35 fascinating facts about conformal cooling that will help you understand its benefits, applications, and how it can revolutionize your manufacturing process. Ready to learn more? Let's get started!

What is Conformal Cooling?

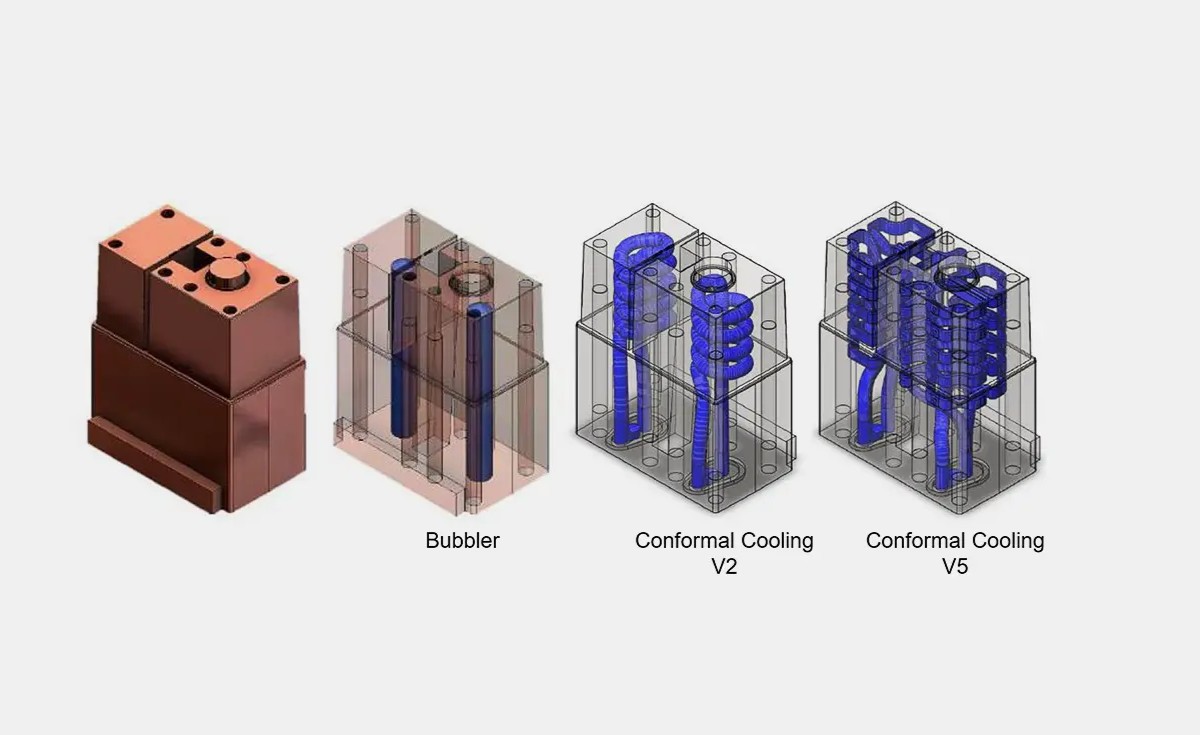

Conformal cooling is a technique used in injection molding to improve the cooling process. This method involves creating cooling channels that follow the contours of the mold, resulting in more efficient and uniform cooling. Here are some fascinating facts about conformal cooling.

-

Enhanced Efficiency: Conformal cooling channels can reduce cooling time by up to 40%, leading to faster production cycles.

-

Uniform Cooling: These channels ensure even cooling across the mold, reducing the risk of warping and defects in the final product.

-

Complex Designs: Conformal cooling allows for intricate channel designs that traditional straight-line cooling cannot achieve.

-

3D Printing: The advent of 3D printing has made it easier to create molds with conformal cooling channels.

-

Material Savings: By reducing cycle times, conformal cooling can lead to significant material savings over time.

Benefits of Conformal Cooling

The advantages of using conformal cooling in injection molding are numerous. Let's explore some of the key benefits.

-

Improved Product Quality: Uniform cooling results in higher-quality products with fewer defects.

-

Energy Efficiency: Faster cooling times mean less energy is required, making the process more environmentally friendly.

-

Cost Savings: Reduced cycle times and improved efficiency lead to lower production costs.

-

Extended Mold Life: Even cooling reduces thermal stress on the mold, extending its lifespan.

-

Better Surface Finish: Products cooled with conformal cooling often have a superior surface finish.

Applications of Conformal Cooling

Conformal cooling is used in various industries to enhance the injection molding process. Here are some notable applications.

-

Automotive Industry: Used to produce high-quality, durable automotive parts.

-

Medical Devices: Ensures precision and reliability in medical device manufacturing.

-

Consumer Electronics: Helps in creating intricate and high-quality electronic components.

-

Packaging: Used to produce durable and aesthetically pleasing packaging materials.

-

Aerospace: Ensures the production of lightweight and strong aerospace components.

Technological Innovations

Recent technological advancements have further improved the effectiveness of conformal cooling. Here are some cutting-edge innovations.

-

Simulation Software: Advanced software can simulate the cooling process, optimizing channel design.

-

Hybrid Manufacturing: Combines traditional and additive manufacturing techniques for better results.

-

Smart Sensors: Embedded sensors monitor the cooling process in real-time, ensuring optimal performance.

-

Advanced Materials: New materials with better thermal conductivity enhance the efficiency of conformal cooling.

-

AI Integration: Artificial intelligence helps in designing more efficient cooling channels.

Challenges and Solutions

Despite its benefits, conformal cooling also presents some challenges. Here are some common issues and their solutions.

-

High Initial Cost: The initial investment can be high, but long-term savings often justify the expense.

-

Complex Design Process: Designing conformal cooling channels is complex, but advanced software can simplify the process.

-

Maintenance: Keeping the channels clean can be challenging, but regular maintenance can mitigate this issue.

-

Material Limitations: Not all materials are suitable for conformal cooling, but ongoing research is expanding the range of usable materials.

-

Training: Specialized training is required to design and implement conformal cooling, but many institutions now offer relevant courses.

Future of Conformal Cooling

The future of conformal cooling looks promising, with ongoing research and development paving the way for new possibilities.

-

Sustainability: Future advancements aim to make conformal cooling even more energy-efficient and environmentally friendly.

-

Integration with IoT: The Internet of Things (IoT) will enable more precise control and monitoring of the cooling process.

-

Customization: Advances in technology will allow for more customized cooling solutions tailored to specific needs.

-

Global Adoption: As awareness grows, more industries worldwide will adopt conformal cooling techniques.

-

Continuous Improvement: Ongoing research will continue to refine and improve conformal cooling methods.

Real-World Examples

Let's look at some real-world examples where conformal cooling has made a significant impact.

-

Nike: Uses conformal cooling to produce high-quality, durable footwear.

-

Tesla: Implements conformal cooling in the production of electric vehicle components.

-

Apple: Utilizes this technique to manufacture intricate and reliable electronic devices.

-

Procter & Gamble: Employs conformal cooling in the production of consumer goods, enhancing product quality and reducing costs.

-

Boeing: Uses conformal cooling to produce lightweight, strong aerospace components, improving overall performance.

Final Thoughts on Conformal Cooling

Conformal cooling is a game-changer in manufacturing. It boosts efficiency, reduces costs, and improves product quality. By using cooling channels that follow the shape of the mold, heat is removed more evenly and quickly. This leads to shorter cycle times and less warping or defects in the final product.

Adopting this technology can give companies a competitive edge. It’s especially useful in industries like automotive, aerospace, and consumer goods. The initial investment might be higher, but the long-term benefits make it worthwhile.

Understanding the basics of conformal cooling helps in making informed decisions. Whether you’re a manufacturer or just curious, knowing how this technology works can be quite enlightening. Keep an eye on advancements in this field; they’re bound to shape the future of manufacturing.

Was this page helpful?

Our commitment to delivering trustworthy and engaging content is at the heart of what we do. Each fact on our site is contributed by real users like you, bringing a wealth of diverse insights and information. To ensure the highest standards of accuracy and reliability, our dedicated editors meticulously review each submission. This process guarantees that the facts we share are not only fascinating but also credible. Trust in our commitment to quality and authenticity as you explore and learn with us.