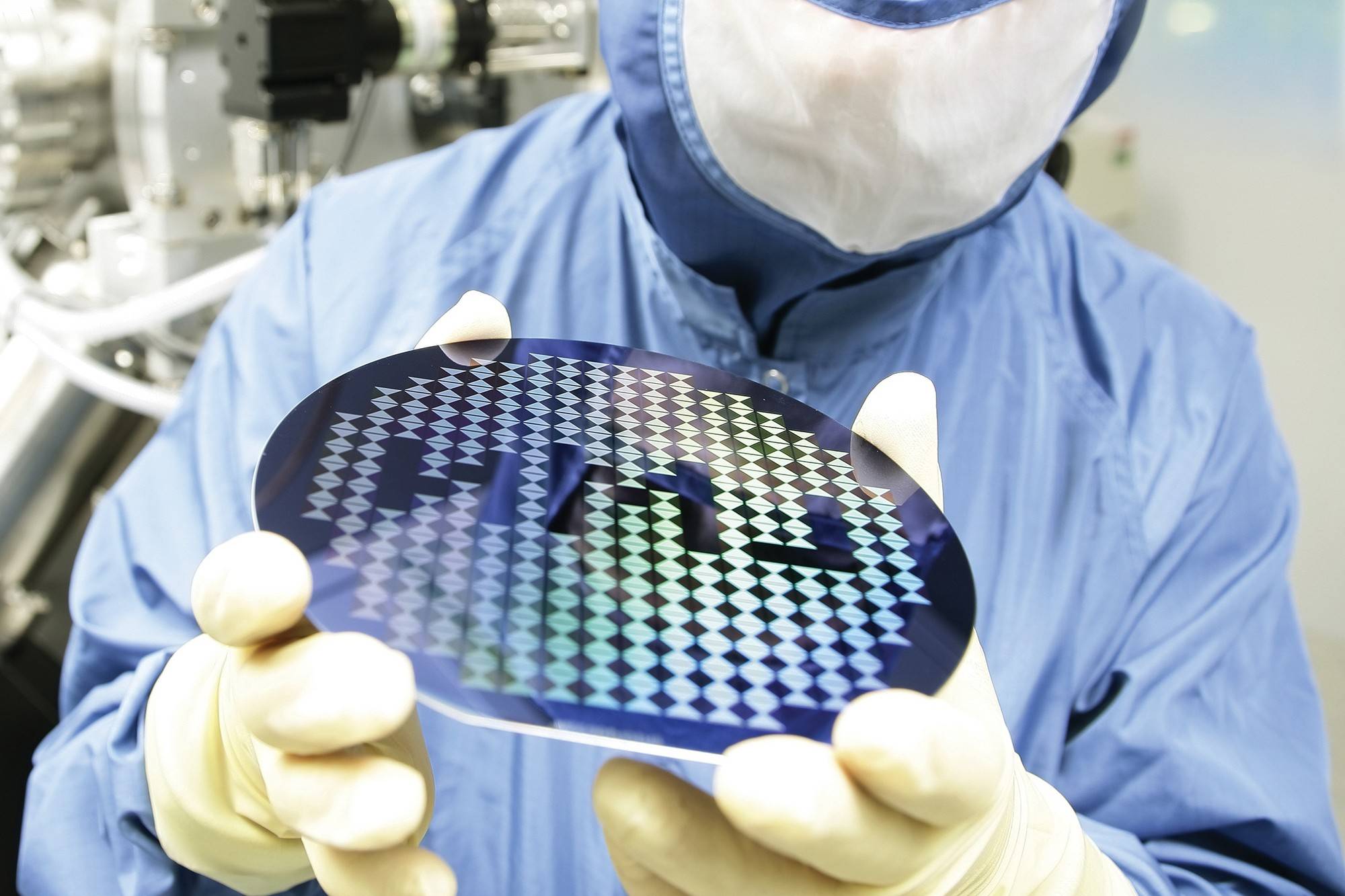

Nanofabrication is the art of building tiny structures, often at the scale of atoms and molecules. But why should you care? Nanofabrication impacts everything from your smartphone to medical devices. Imagine creating materials stronger than steel yet lighter than plastic. This field combines physics, chemistry, and engineering to push the boundaries of what's possible. Nanofabrication techniques include lithography, etching, and self-assembly, each with unique applications. Whether it's improving solar panels or developing new drug delivery systems, the potential is vast. Ready to dive into 34 mind-blowing facts about nanofabrication? Let's get started!

What is Nanofabrication?

Nanofabrication is the process of designing and creating devices on a nanometer scale. This technology is crucial for developing smaller, faster, and more efficient electronic devices. Let's dive into some fascinating facts about nanofabrication.

-

Nanofabrication involves manipulating materials at the atomic or molecular level, typically between 1 and 100 nanometers.

-

One nanometer is one-billionth of a meter, which is about 100,000 times smaller than the diameter of a human hair.

-

The field of nanofabrication emerged in the late 20th century, driven by advancements in semiconductor technology.

-

Nanofabrication techniques are used to create transistors, the building blocks of modern electronic devices.

-

The most common methods of nanofabrication include photolithography, electron beam lithography, and nanoimprint lithography.

Techniques in Nanofabrication

Different techniques are employed to achieve the precision required in nanofabrication. Each method has its unique advantages and applications.

-

Photolithography uses light to transfer a geometric pattern from a photomask to a light-sensitive chemical photoresist on the substrate.

-

Electron beam lithography uses a focused beam of electrons to create extremely fine patterns, allowing for higher resolution than photolithography.

-

Nanoimprint lithography involves pressing a mold with nanoscale features into a substrate to create patterns.

-

Atomic layer deposition is a technique that deposits thin films one atomic layer at a time, ensuring precise control over thickness and composition.

-

Focused ion beam milling uses a beam of ions to etch away material, allowing for direct writing of nanoscale features.

Applications of Nanofabrication

Nanofabrication has a wide range of applications, from electronics to medicine. Its impact on various fields is profound.

-

In electronics, nanofabrication is used to create smaller, faster, and more efficient transistors for integrated circuits.

-

Nanofabrication techniques are employed in the production of quantum dots, which are used in displays and solar cells.

-

In medicine, nanofabrication is used to create drug delivery systems that can target specific cells or tissues.

-

Nanofabricated sensors can detect minute changes in the environment, making them useful for environmental monitoring.

-

The technology is also used in the development of nanoscale mechanical systems, such as nanomotors and nanogears.

Challenges in Nanofabrication

Despite its potential, nanofabrication faces several challenges that researchers are working to overcome.

-

One major challenge is achieving uniformity and consistency at such a small scale, as even minor variations can affect performance.

-

Contamination control is critical, as particles or impurities can disrupt the fabrication process.

-

The cost of nanofabrication equipment and materials is high, making it expensive to develop and produce nanoscale devices.

-

Scaling up production from laboratory to industrial scale while maintaining precision is a significant hurdle.

-

Ensuring the long-term stability and reliability of nanofabricated devices is essential for their practical application.

Future of Nanofabrication

The future of nanofabrication holds exciting possibilities, with ongoing research and development paving the way for new innovations.

-

Researchers are exploring the use of DNA as a template for nanofabrication, leveraging its ability to self-assemble into precise structures.

-

Advances in 3D nanofabrication techniques could enable the creation of complex, multi-layered nanoscale devices.

-

The development of new materials, such as graphene and carbon nanotubes, offers potential for improved performance and new applications.

-

Integration of artificial intelligence and machine learning in nanofabrication processes could enhance precision and efficiency.

-

Nanofabrication could play a key role in the development of next-generation computing technologies, such as quantum computing.

Environmental and Ethical Considerations

As with any advanced technology, nanofabrication raises important environmental and ethical questions that need to be addressed.

-

The production and disposal of nanomaterials can have environmental impacts, necessitating the development of sustainable practices.

-

There are concerns about the potential health effects of exposure to nanomaterials, requiring thorough safety assessments.

-

Ethical considerations include the potential for misuse of nanotechnology in surveillance or weaponry.

-

Ensuring equitable access to nanofabrication technology is important to prevent widening the gap between developed and developing regions.

-

Public engagement and education about nanofabrication are crucial for informed decision-making and responsible development.

Interesting Facts About Nanofabrication

Here are some intriguing tidbits that highlight the wonder and complexity of nanofabrication.

-

The concept of nanotechnology was first introduced by physicist Richard Feynman in his famous 1959 lecture, "There's Plenty of Room at the Bottom."

-

The smallest transistor ever created using nanofabrication measures just one nanometer in length.

-

Nanofabrication techniques have enabled the creation of invisibility cloaks by manipulating light at the nanoscale.

-

Researchers have used nanofabrication to create tiny robots, known as nanobots, that can perform tasks inside the human body.

The Future of Nanofabrication

Nanofabrication is changing the world in ways we never thought possible. From medical advancements to environmental solutions, its impact is undeniable. This technology is not just about making things smaller; it's about making them better, more efficient, and more sustainable. As researchers continue to push the boundaries, we can expect even more innovative applications to emerge.

Whether it's in electronics, medicine, or energy, nanofabrication holds the key to solving some of our most pressing challenges. Staying informed about these advancements can help us understand the potential and prepare for a future where nanotechnology plays a crucial role in our daily lives.

So, keep an eye on this fascinating field. The tiny world of nanofabrication is set to make a big impact.

Was this page helpful?

Our commitment to delivering trustworthy and engaging content is at the heart of what we do. Each fact on our site is contributed by real users like you, bringing a wealth of diverse insights and information. To ensure the highest standards of accuracy and reliability, our dedicated editors meticulously review each submission. This process guarantees that the facts we share are not only fascinating but also credible. Trust in our commitment to quality and authenticity as you explore and learn with us.