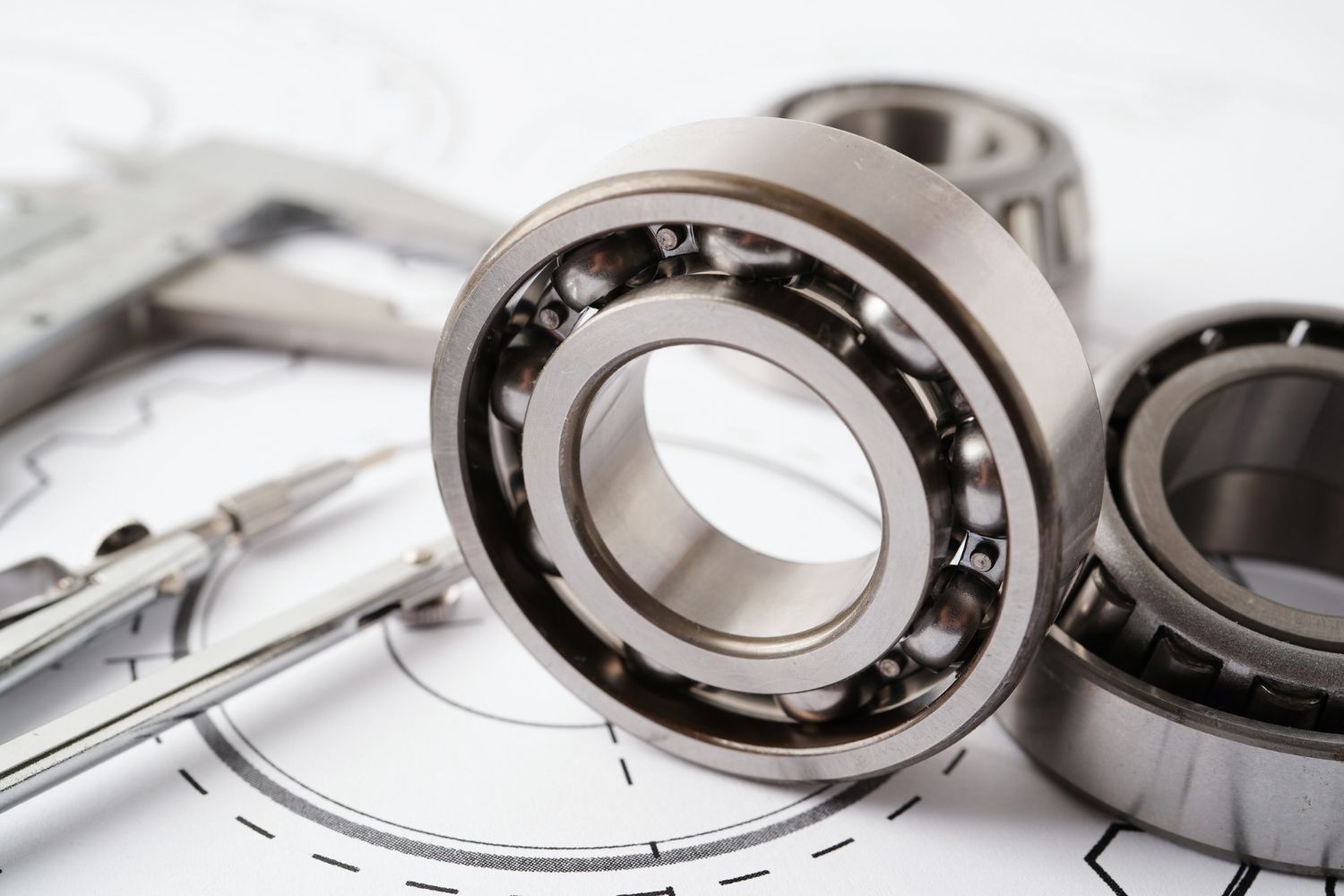

Geometric Dimensioning and Tolerancing (GD&T) is a system used in engineering and manufacturing to define and communicate tolerances. GD&T ensures that parts fit together correctly, regardless of slight variations in manufacturing. This system uses symbols to describe the allowable variations in a part's geometry. Why is GD&T important? It helps reduce errors, improve quality, and save costs by providing clear, concise instructions. Engineers and machinists rely on GD&T to ensure parts are made to exact specifications. Understanding GD&T can be a game-changer for anyone involved in design or production. Ready to dive into 34 fascinating facts about GD&T? Let's get started!

What is Geometric Dimensioning and Tolerancing (GD&T)?

Geometric Dimensioning and Tolerancing (GD&T) is a system used in engineering and manufacturing to define and communicate tolerances. It ensures parts fit together correctly, even when manufactured by different suppliers. Here are some fascinating facts about GD&T.

-

GD&T Origins: GD&T was developed during World War II to improve the interchangeability of parts in mass production.

-

ASME Standard: The American Society of Mechanical Engineers (ASME) standardized GD&T in the Y14.5 standard.

-

Symbols and Terms: GD&T uses a set of symbols and terms to describe the geometry and allowable variation of parts.

-

Feature Control Frame: This is a rectangular box containing the geometric characteristics and tolerance information.

-

Datum Reference Frame: Datums are reference points, lines, or surfaces on a part used to establish a coordinate system.

-

Tolerance Zones: These define the allowable variation in a part's geometry.

-

Form Tolerances: These control the shape of features, such as flatness, straightness, circularity, and cylindricity.

-

Orientation Tolerances: These control the tilt of features, including angularity, perpendicularity, and parallelism.

-

Location Tolerances: These control the position of features, such as position, concentricity, and symmetry.

-

Profile Tolerances: These control the outline of features, including profile of a line and profile of a surface.

-

Runout Tolerances: These control the wobble of features, including circular runout and total runout.

-

Bonus Tolerance: This allows for additional tolerance when a feature is at its maximum material condition.

-

Material Condition Modifiers: These indicate the condition of a feature, such as maximum material condition (MMC) or least material condition (LMC).

-

True Position: This is the exact coordinate location of a feature.

-

Virtual Condition: This is a boundary that a feature must not violate.

-

Composite Tolerancing: This allows for multiple tolerances to be applied to a single feature.

-

Datum Targets: These are specific points, lines, or areas on a part used to establish a datum reference frame.

-

Feature of Size: This refers to a feature that can be measured for size, such as a hole or a slot.

-

Functional Gaging: This is a method of inspecting parts using gages that simulate the assembly conditions.

-

Statistical Tolerancing: This uses statistical methods to determine tolerances based on the variation in the manufacturing process.

-

Tolerance Stacks: These are the cumulative effects of individual tolerances on the overall assembly.

-

Inspection Methods: GD&T can be inspected using various methods, such as coordinate measuring machines (CMMs) or optical comparators.

-

Training and Certification: There are training programs and certifications available for GD&T, such as those offered by ASME.

-

Software Tools: There are software tools available to help design and inspect parts using GD&T.

-

Global Use: GD&T is used worldwide in various industries, including automotive, aerospace, and electronics.

-

Improves Communication: GD&T improves communication between designers, manufacturers, and inspectors.

-

Reduces Errors: By clearly defining tolerances, GD&T reduces errors in manufacturing and assembly.

-

Increases Efficiency: GD&T increases efficiency by allowing for more precise and consistent parts.

-

Enhances Quality: By ensuring parts fit together correctly, GD&T enhances the overall quality of products.

-

Cost Savings: GD&T can lead to cost savings by reducing the need for rework and scrap.

-

Flexibility: GD&T provides flexibility in manufacturing by allowing for variations within specified limits.

-

Interchangeability: GD&T ensures parts are interchangeable, even when produced by different manufacturers.

-

Design Intent: GD&T helps convey the design intent of a part, ensuring it functions as intended.

-

Continuous Improvement: GD&T is continuously evolving, with updates to standards and practices to keep up with advancements in technology and manufacturing.

The Power of GD&T

Geometric dimensioning and tolerancing (GD&T) is a game-changer in manufacturing. It ensures parts fit together perfectly, reducing errors and saving time. By using symbols and standards, GD&T provides a universal language for engineers and machinists. This leads to better communication and fewer misunderstandings.

GD&T also boosts quality control. It allows for precise measurements, ensuring each part meets strict specifications. This precision results in higher-quality products and increased customer satisfaction.

Moreover, GD&T is cost-effective. It minimizes waste by reducing the need for rework and scrap. Companies can produce parts more efficiently, leading to significant savings.

Understanding GD&T is crucial for anyone in the manufacturing industry. It enhances productivity, quality, and cost-efficiency. So, if you're looking to improve your manufacturing processes, mastering GD&T is a smart move. It’s not just a set of rules; it’s a pathway to excellence.

Was this page helpful?

Our commitment to delivering trustworthy and engaging content is at the heart of what we do. Each fact on our site is contributed by real users like you, bringing a wealth of diverse insights and information. To ensure the highest standards of accuracy and reliability, our dedicated editors meticulously review each submission. This process guarantees that the facts we share are not only fascinating but also credible. Trust in our commitment to quality and authenticity as you explore and learn with us.