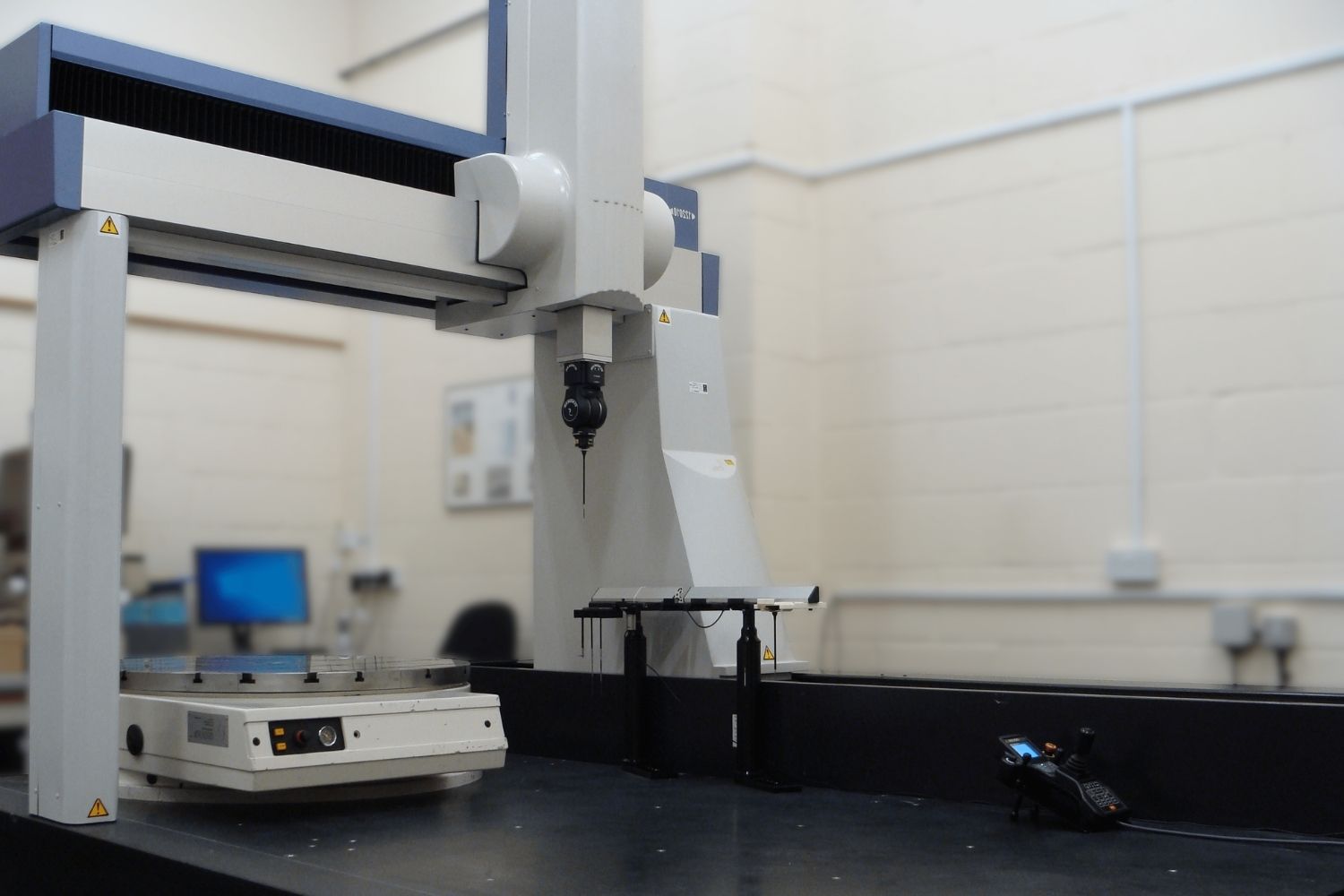

What is a Coordinate Measuring Machine (CMM)? A Coordinate Measuring Machine (CMM) is a device used in manufacturing and assembly processes to measure the physical geometrical characteristics of an object. These machines can be operated manually or controlled via computer. They use a probe to detect discrete points on the surface of the object, which are then used to determine dimensions, angles, and shapes. CMMs are essential for ensuring precision and accuracy in the production of complex parts, making them invaluable in industries like aerospace, automotive, and electronics. With their ability to provide detailed measurements, CMMs help maintain quality control and improve product consistency.

What is a Coordinate Measuring Machine (CMM)?

A Coordinate Measuring Machine (CMM) is a device used in manufacturing and assembly processes to measure the physical geometrical characteristics of an object. This machine can be operated manually or controlled via computer. Here are some fascinating facts about CMMs:

-

CMMs use a probe to detect discrete points on the surface of an object, which helps in creating a detailed map of its dimensions.

-

These machines can measure objects in three dimensions: X, Y, and Z axes.

-

CMMs are essential in quality control processes, ensuring that parts meet precise specifications.

Types of Coordinate Measuring Machines

There are various types of CMMs, each designed for specific applications and environments. Understanding these types can help in choosing the right machine for your needs.

-

Bridge CMMs are the most common type, featuring a bridge-like structure that moves along the X and Y axes.

-

Cantilever CMMs have a single arm that extends over the measuring area, ideal for small to medium-sized parts.

-

Gantry CMMs are large machines used for measuring big objects, often found in aerospace and automotive industries.

-

Horizontal Arm CMMs are designed for measuring large, flat objects and are commonly used in the automotive sector.

How CMMs Work

Understanding the working principles of CMMs can provide insight into their accuracy and efficiency.

-

The probe of a CMM touches the object's surface to collect data points, which are then used to create a 3D model.

-

CMMs can be equipped with various types of probes, including touch-trigger, scanning, and optical probes.

-

The machine's software processes the collected data to provide precise measurements and generate detailed reports.

Applications of CMMs

CMMs are versatile tools used in various industries for different applications. Here are some common uses:

-

Automotive Industry: CMMs ensure that car parts meet stringent quality standards.

-

Aerospace Industry: These machines measure complex components like turbine blades and aircraft fuselages.

-

Medical Device Manufacturing: CMMs help in producing precise medical instruments and implants.

-

Electronics Industry: They are used to measure small, intricate components in electronic devices.

Advantages of Using CMMs

CMMs offer several benefits that make them indispensable in modern manufacturing. Here are some advantages:

-

High Accuracy: CMMs provide extremely precise measurements, reducing the risk of errors.

-

Efficiency: These machines can measure multiple dimensions simultaneously, speeding up the inspection process.

-

Versatility: CMMs can measure a wide range of objects, from tiny electronic components to large aerospace parts.

-

Data Storage: The software can store measurement data for future reference and analysis.

Challenges and Limitations

Despite their advantages, CMMs also have some challenges and limitations. Understanding these can help in making informed decisions.

-

Cost: CMMs can be expensive to purchase and maintain.

-

Complexity: Operating a CMM requires specialized training and expertise.

-

Environmental Sensitivity: CMMs are sensitive to temperature changes and vibrations, which can affect their accuracy.

-

Size Limitations: While some CMMs can measure large objects, others are limited to smaller parts.

Innovations in CMM Technology

The field of CMM technology is continually evolving, with new innovations enhancing their capabilities. Here are some recent advancements:

-

Portable CMMs: These are lightweight and can be easily moved to different locations for on-site measurements.

-

Laser Scanning Probes: These probes use laser technology to capture detailed surface data quickly.

-

Automated CMMs: Integration with robotic systems allows for fully automated measurement processes.

-

Software Improvements: Advanced software offers better data analysis, reporting, and integration with other systems.

Maintenance and Calibration

Proper maintenance and calibration are crucial for ensuring the accuracy and longevity of CMMs. Here are some key points:

-

Regular Calibration: CMMs need to be calibrated regularly to maintain their accuracy.

-

Cleaning: Keeping the machine clean, especially the probe, is essential for accurate measurements.

-

Software Updates: Regularly updating the software ensures that the machine operates efficiently and accurately.

-

Environmental Control: Maintaining a stable environment with controlled temperature and minimal vibrations is crucial.

Future of CMMs

The future of CMM technology looks promising, with ongoing research and development paving the way for more advanced machines. Here are some trends to watch:

-

Artificial Intelligence: AI integration could enhance the machine's ability to analyze data and make decisions.

-

IoT Connectivity: Connecting CMMs to the Internet of Things (IoT) can enable real-time monitoring and data sharing.

-

Enhanced User Interfaces: Future CMMs may feature more intuitive and user-friendly interfaces, making them easier to operate.

The Final Word on CMM Facts

Coordinate measuring machines (CMMs) are game-changers in precision measurement. They ensure accuracy in manufacturing, boost quality control, and reduce errors. From their history to their modern applications, CMMs have evolved significantly. They’re essential in industries like aerospace, automotive, and electronics.

Understanding CMMs helps appreciate their role in producing high-quality products. They’re not just tools but vital components in the production process. Knowing these 33 facts gives insight into their importance and functionality.

Whether you’re a student, engineer, or just curious, these facts highlight why CMMs matter. They’re more than just machines; they’re the backbone of precision in manufacturing. Keep these facts in mind next time you see a product with perfect dimensions. It’s likely a CMM played a part in its creation.

Was this page helpful?

Our commitment to delivering trustworthy and engaging content is at the heart of what we do. Each fact on our site is contributed by real users like you, bringing a wealth of diverse insights and information. To ensure the highest standards of accuracy and reliability, our dedicated editors meticulously review each submission. This process guarantees that the facts we share are not only fascinating but also credible. Trust in our commitment to quality and authenticity as you explore and learn with us.