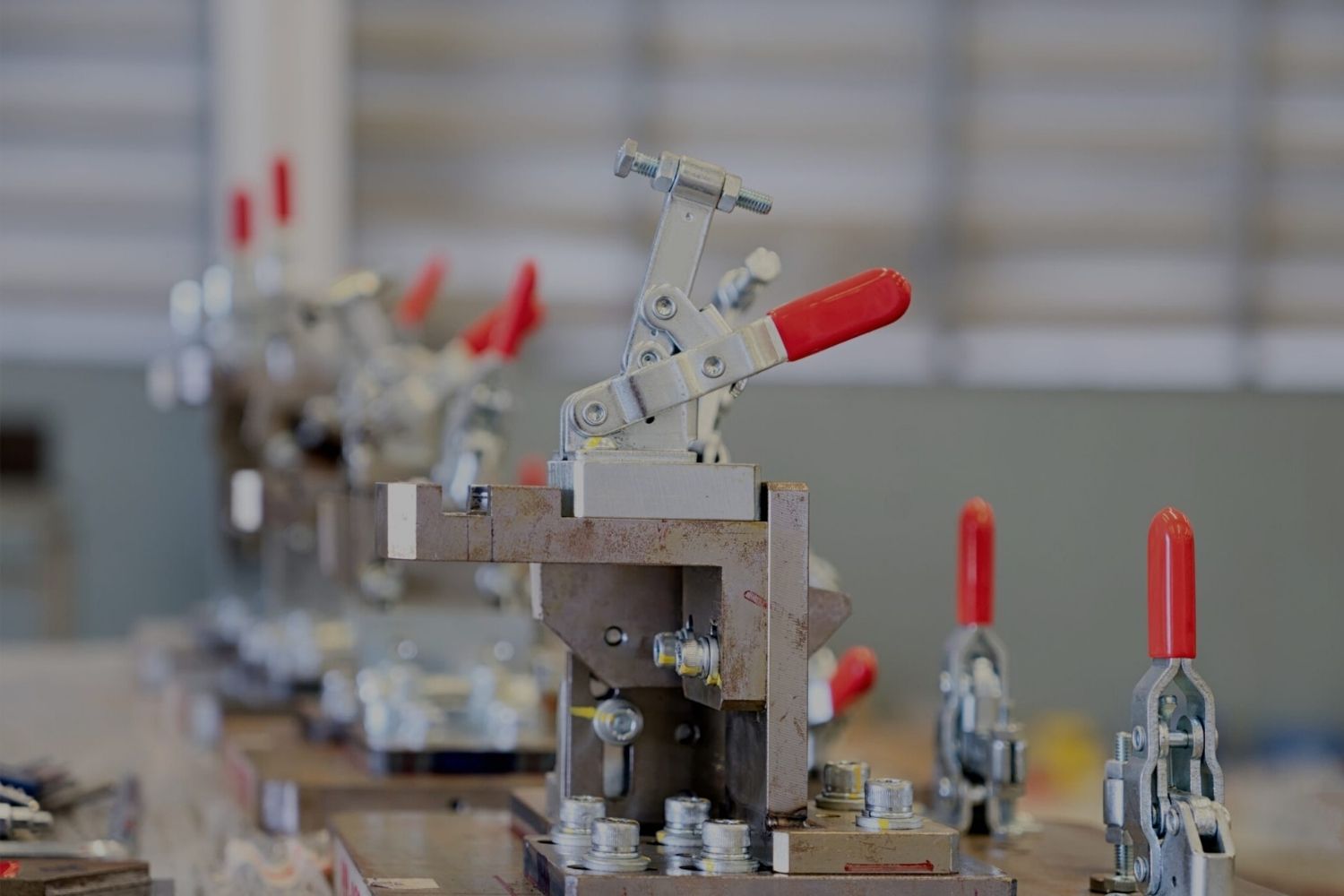

Jig and fixture design might sound like a niche topic, but it plays a crucial role in manufacturing. These tools ensure precision, efficiency, and safety in production lines. Jigs guide tools like drills, while fixtures hold workpieces in place. Imagine trying to drill a hole in a piece of metal without a jig—crooked holes and wasted materials would be common. Fixtures, on the other hand, keep parts steady during machining, ensuring consistent quality. Understanding these tools can lead to better products and smoother operations. Ready to dive into the world of jigs and fixtures? Let's explore 29 fascinating facts about their design and importance.

What is Jig and Fixture Design?

Jig and fixture design is a crucial aspect of manufacturing. These tools ensure precision, efficiency, and consistency in the production process. Let's dive into some fascinating facts about this essential engineering field.

-

Jigs and Fixtures Defined: Jigs guide the cutting tool, while fixtures hold the workpiece in place. Both are essential for accurate and repeatable manufacturing.

-

Historical Roots: The concept dates back to the early 19th century, revolutionizing the way products were made during the Industrial Revolution.

-

Material Matters: Common materials for jigs and fixtures include steel, aluminum, and sometimes even plastic, depending on the application.

-

Customization is Key: Each jig and fixture is often custom-designed for a specific task, ensuring optimal performance and precision.

Importance in Manufacturing

Jigs and fixtures play a pivotal role in modern manufacturing. They enhance productivity, reduce errors, and ensure high-quality output.

-

Boosts Efficiency: By holding parts in place and guiding tools, these devices significantly speed up the manufacturing process.

-

Reduces Human Error: With precise guidance and secure holding, the chances of mistakes are minimized, leading to higher quality products.

-

Consistency is King: Using jigs and fixtures ensures that each part produced is identical, maintaining uniformity across large production runs.

-

Cost-Effective: Though the initial design and production of jigs and fixtures can be costly, they save money in the long run by reducing waste and rework.

Types of Jigs and Fixtures

There are various types of jigs and fixtures, each designed for specific tasks and applications.

-

Drill Jigs: These guide the drill bit to the correct location, ensuring precise hole placement.

-

Milling Fixtures: Used in milling operations, these fixtures hold the workpiece steady while the milling cutter removes material.

-

Welding Fixtures: These hold parts in place during welding, ensuring accurate alignment and strong welds.

-

Assembly Jigs: These assist in the assembly of components, ensuring each part is correctly positioned and secured.

Design Considerations

Designing jigs and fixtures requires careful planning and consideration of various factors to ensure they meet the specific needs of the task.

-

Workpiece Size and Shape: The design must accommodate the dimensions and geometry of the workpiece.

-

Tool Access: Ensure that tools can easily reach the workpiece without obstruction.

-

Clamping Mechanism: The clamping system must securely hold the workpiece without causing damage.

-

Ease of Use: Operators should be able to use the jig or fixture with minimal effort and training.

Technological Advancements

Technology has significantly impacted jig and fixture design, making them more efficient and versatile.

-

CAD Software: Computer-aided design (CAD) software allows for precise and detailed designs, reducing errors and improving efficiency.

-

3D Printing: Additive manufacturing, or 3D printing, enables rapid prototyping and production of complex jigs and fixtures.

-

Automation: Automated systems can integrate jigs and fixtures, further enhancing productivity and precision.

-

Material Innovations: Advances in materials science have led to stronger, lighter, and more durable jigs and fixtures.

Real-World Applications

Jigs and fixtures are used across various industries, each with unique requirements and challenges.

-

Automotive Industry: Essential for assembling car parts, ensuring each component is accurately positioned and securely fastened.

-

Aerospace: Precision is critical in aerospace manufacturing, making jigs and fixtures indispensable for producing high-quality components.

-

Electronics: Used in the assembly of circuit boards and other electronic components, ensuring precise placement and soldering.

-

Medical Devices: Critical for manufacturing medical devices, where precision and consistency are paramount.

Challenges and Solutions

Despite their benefits, designing and using jigs and fixtures can present challenges. However, solutions are available to overcome these obstacles.

-

Complex Designs: Some tasks require highly complex jigs and fixtures, which can be difficult and time-consuming to design. Advanced CAD software and 3D printing can help streamline this process.

-

Wear and Tear: Over time, jigs and fixtures can wear out, leading to reduced accuracy. Regular maintenance and using durable materials can mitigate this issue.

-

Initial Cost: The upfront cost of designing and producing jigs and fixtures can be high. However, the long-term savings in efficiency and reduced waste often justify the investment.

-

Operator Training: Ensuring that operators are properly trained to use jigs and fixtures is essential for maximizing their benefits. Comprehensive training programs can address this need.

-

Adaptability: As manufacturing processes evolve, jigs and fixtures must be adaptable to new requirements. Modular designs and flexible systems can provide the necessary versatility.

The Final Piece

Jig and fixture design is a game-changer in manufacturing. These tools boost efficiency, ensure precision, and cut down on production time. By understanding their role, you can appreciate how they streamline processes and enhance product quality. Whether you're a seasoned engineer or just curious, knowing these facts can give you a new perspective on the importance of jigs and fixtures in the industry.

Remember, the right design can make all the difference. It’s not just about holding parts in place; it’s about improving the entire workflow. So next time you see a perfectly crafted product, think about the jigs and fixtures behind the scenes making it all possible. Keep these facts in mind, and you'll see the manufacturing world in a whole new light.

Was this page helpful?

Our commitment to delivering trustworthy and engaging content is at the heart of what we do. Each fact on our site is contributed by real users like you, bringing a wealth of diverse insights and information. To ensure the highest standards of accuracy and reliability, our dedicated editors meticulously review each submission. This process guarantees that the facts we share are not only fascinating but also credible. Trust in our commitment to quality and authenticity as you explore and learn with us.