What is an in-circuit tester? An in-circuit tester (ICT) is a device used to check the functionality of electronic circuits and components on a printed circuit board (PCB). It ensures each part works correctly by probing the board and measuring electrical properties like resistance, capacitance, and voltage. This helps identify manufacturing defects, such as short circuits or open circuits, before the product reaches the consumer. ICTs are essential in the electronics industry for maintaining high-quality standards and reducing the risk of faulty products. They are widely used in the production of everything from smartphones to medical devices.

What is an In-Circuit Tester?

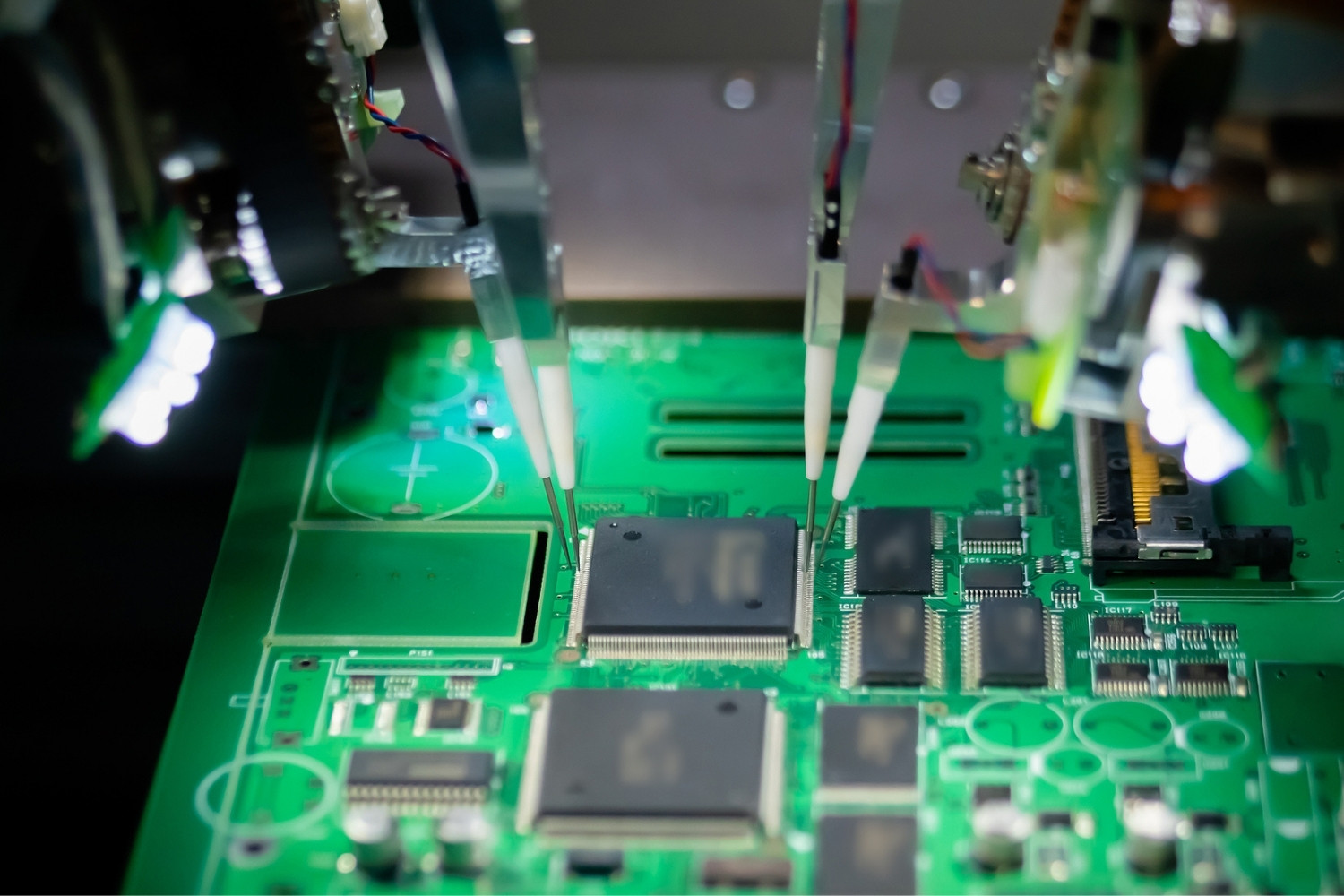

An In-Circuit Tester (ICT) is a powerful tool used in electronics manufacturing to test the functionality of assembled printed circuit boards (PCBs). It checks for defects like shorts, opens, and component values. Here are some intriguing facts about ICTs.

-

ICTs can test both analog and digital components on a PCB. This versatility makes them essential in modern electronics manufacturing.

-

They use a bed of nails fixture. This fixture has numerous spring-loaded pins that make contact with test points on the PCB.

-

ICTs can detect manufacturing defects. These include missing components, wrong components, and soldering issues.

-

They measure electrical characteristics. This includes resistance, capacitance, and inductance of components on the PCB.

-

ICTs can perform functional tests. These tests ensure that the PCB operates correctly within its intended circuit.

How Does an In-Circuit Tester Work?

Understanding the working mechanism of an ICT can help appreciate its importance in quality control.

-

ICTs apply a small voltage to test points. This helps in measuring the response of various components.

-

They use a combination of hardware and software. The hardware includes the bed of nails fixture, while the software analyzes the test results.

-

ICTs can isolate faults. By testing individual components, they can pinpoint the exact location of a defect.

-

They use a matrix of switches. This matrix connects the test points to the measurement instruments.

-

ICTs can test multiple boards simultaneously. This increases efficiency in high-volume manufacturing.

Benefits of Using In-Circuit Testers

ICTs offer numerous advantages that make them indispensable in the electronics industry.

-

They improve product quality. By detecting defects early, ICTs ensure that only functional products reach the market.

-

ICTs reduce manufacturing costs. Early detection of defects prevents costly rework and scrap.

-

They speed up the testing process. Automated testing is faster than manual inspection.

-

ICTs provide detailed test reports. These reports help in diagnosing and fixing defects.

-

They are highly reliable. ICTs have a high fault coverage, making them more reliable than other testing methods.

Types of In-Circuit Testers

There are different types of ICTs, each suited for specific testing needs.

-

Analog ICTs. These test analog components like resistors, capacitors, and inductors.

-

Digital ICTs. These are used for testing digital components like microcontrollers and logic gates.

-

Mixed-signal ICTs. These can test both analog and digital components.

-

Flying probe testers. These use moving probes to make contact with test points, eliminating the need for a bed of nails fixture.

-

Boundary scan testers. These use a technique called boundary scan to test components without physical contact.

Challenges in Using In-Circuit Testers

Despite their benefits, ICTs come with their own set of challenges.

-

High initial cost. Setting up an ICT system can be expensive.

-

Complex fixture design. Designing the bed of nails fixture requires precision and expertise.

-

Limited access to test points. In densely packed PCBs, accessing all test points can be difficult.

-

Time-consuming setup. Setting up the ICT for a new PCB design can take time.

-

Maintenance requirements. Regular maintenance is needed to keep the ICT system in good working condition.

Innovations in In-Circuit Testing

The field of in-circuit testing is constantly evolving, with new innovations making the process more efficient.

-

Automated fixture design. Software tools can now automate the design of the bed of nails fixture.

-

Advanced fault diagnosis. Modern ICTs use sophisticated algorithms for more accurate fault diagnosis.

-

Integration with other testing methods. ICTs can be integrated with functional testers and boundary scan testers for comprehensive testing.

-

Wireless testing. Some ICTs now use wireless technology to reduce the complexity of the test setup.

-

Miniaturization. Advances in technology have led to smaller, more compact ICT systems.

Real-World Applications of In-Circuit Testers

ICTs are used in various industries to ensure the quality and reliability of electronic products.

-

Consumer electronics. ICTs are used to test smartphones, tablets, and other consumer gadgets.

-

Automotive industry. They ensure the reliability of electronic components in vehicles.

-

Aerospace industry. ICTs are used to test critical electronic systems in aircraft.

-

Medical devices. They ensure the safety and functionality of electronic medical equipment.

-

Telecommunications. ICTs test the reliability of communication devices and infrastructure.

-

Industrial automation. They are used to test control systems and other industrial electronics.

The Final Word on In-Circuit Testers

In-circuit testers (ICTs) are essential for ensuring the quality and reliability of electronic assemblies. They check for short circuits, open circuits, resistor values, capacitor values, and diode functionality. ICTs help identify manufacturing defects early, saving time and money. They also support high-volume production by providing quick and accurate testing.

Understanding the different types of ICTs, such as bed-of-nails and flying probe testers, helps in choosing the right one for specific needs. Each type has its own advantages, like speed or flexibility, making them suitable for various applications.

Investing in a good ICT can significantly improve product quality, reduce warranty claims, and enhance customer satisfaction. So, whether you're a manufacturer or a hobbyist, knowing about ICTs can make a big difference in your projects. Keep these facts in mind, and you'll be well-equipped to tackle any testing challenges that come your way.

Was this page helpful?

Our commitment to delivering trustworthy and engaging content is at the heart of what we do. Each fact on our site is contributed by real users like you, bringing a wealth of diverse insights and information. To ensure the highest standards of accuracy and reliability, our dedicated editors meticulously review each submission. This process guarantees that the facts we share are not only fascinating but also credible. Trust in our commitment to quality and authenticity as you explore and learn with us.