Laser cutters and engravers have revolutionized how we create and customize items. These powerful tools can cut, engrave, and etch various materials with incredible precision. But what makes them so special? Laser cutters use a focused beam of light to slice through materials like wood, acrylic, and even metal. Engravers, on the other hand, are perfect for adding intricate designs to surfaces. Whether you're a hobbyist or a professional, understanding these machines can open up a world of creative possibilities. From crafting personalized gifts to prototyping new products, the potential is endless. Ready to learn more? Let's dive into 33 fascinating facts about these amazing devices!

What is a Laser Cutter/Engraver?

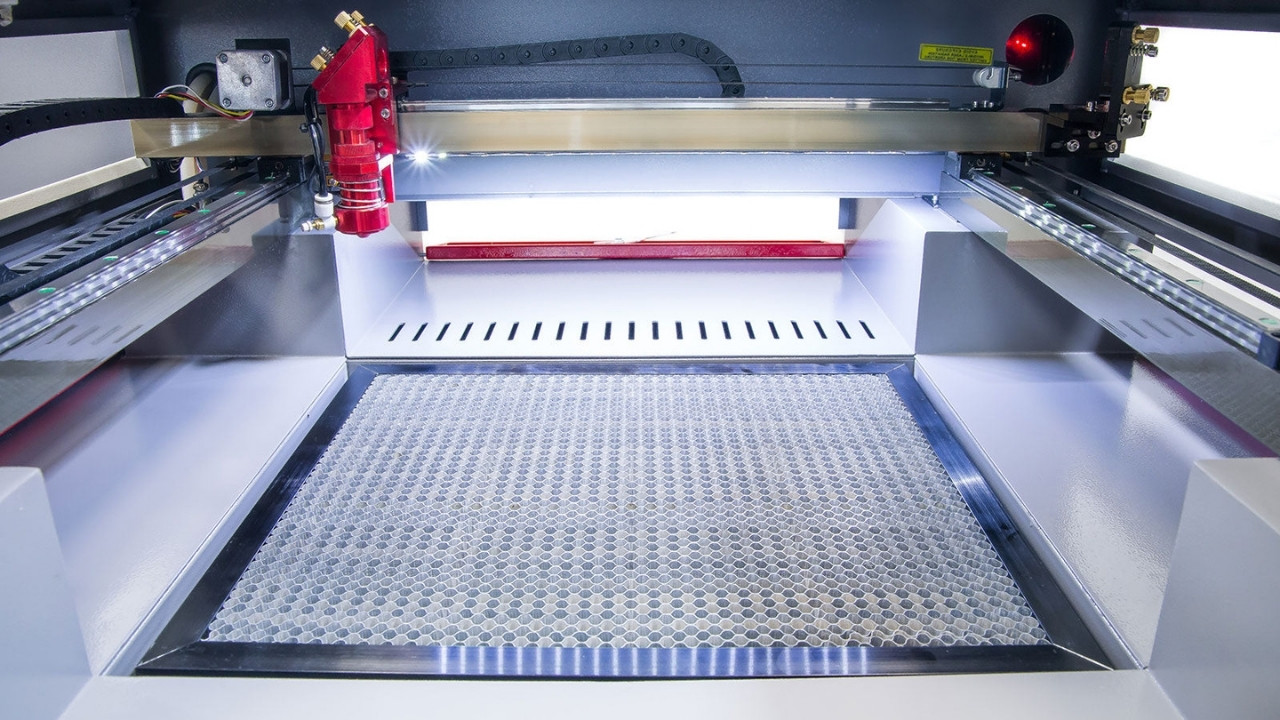

Laser cutters and engravers are powerful tools used in various industries for cutting, engraving, and marking materials. These machines use a focused beam of light to cut through or engrave designs onto surfaces with precision and speed.

-

Laser cutters can cut through a variety of materials. They can handle wood, acrylic, plastic, fabric, leather, and even some metals, making them versatile for different projects.

-

Engraving is different from cutting. While cutting slices through materials, engraving only removes the surface layer to create designs or text.

-

CO2 lasers are common in laser cutters. These lasers are efficient and effective for cutting non-metal materials.

-

Fiber lasers are used for metals. Fiber lasers are more powerful and can cut through metals like steel and aluminum.

-

Laser cutters can achieve high precision. They can cut intricate designs with accuracy down to fractions of a millimeter.

How Do Laser Cutters/Engravers Work?

Understanding the working mechanism of laser cutters and engravers can help appreciate their capabilities.

-

Lasers use a beam of light. This beam is focused through lenses to a small point, creating intense heat that cuts or engraves the material.

-

Computer-controlled for precision. Laser cutters are often controlled by computer software, allowing for precise and repeatable designs.

-

Speed and power settings matter. Adjusting these settings can control the depth and quality of cuts and engravings.

-

Air assist improves quality. Blowing air at the cutting point helps remove debris and cools the material, resulting in cleaner cuts.

-

Different lenses for different tasks. Lenses with various focal lengths can be used to optimize cutting or engraving for different materials and thicknesses.

Applications of Laser Cutters/Engravers

Laser cutters and engravers have a wide range of applications across different fields.

-

Used in manufacturing. They are essential in industries like automotive, aerospace, and electronics for precise cutting and marking.

-

Popular in arts and crafts. Artists and hobbyists use laser cutters to create intricate designs and custom pieces.

-

Signage and advertising. Laser engraving is used to create detailed and durable signs and promotional materials.

-

Jewelry making. Precision cutting and engraving allow for the creation of detailed and custom jewelry pieces.

-

Medical device manufacturing. Lasers are used to cut and engrave medical devices with high precision.

Benefits of Using Laser Cutters/Engravers

There are numerous advantages to using laser cutters and engravers in various applications.

-

High precision and accuracy. Laser cutters can produce detailed and intricate designs with minimal error.

-

Speed and efficiency. They can complete tasks quickly, increasing productivity.

-

Versatility. Able to work with a wide range of materials, they are suitable for many different projects.

-

Non-contact process. The laser beam does not physically touch the material, reducing the risk of damage.

-

Minimal waste. Laser cutting is precise, reducing material waste and saving costs.

Safety and Maintenance of Laser Cutters/Engravers

Safety and proper maintenance are crucial for the effective and safe operation of laser cutters and engravers.

-

Proper ventilation is necessary. Laser cutting can produce fumes and particles, so good ventilation is essential.

-

Regular cleaning. Keeping the machine clean ensures optimal performance and longevity.

-

Eye protection is a must. Lasers can be harmful to eyes, so wearing protective eyewear is important.

-

Routine checks and calibration. Regularly checking and calibrating the machine ensures it operates correctly and safely.

-

Training and certification. Proper training for operators can prevent accidents and ensure efficient use of the machine.

Innovations in Laser Cutting/Engraving Technology

The technology behind laser cutters and engravers continues to evolve, bringing new capabilities and improvements.

-

Advancements in laser power. Newer lasers are more powerful, allowing for faster and deeper cuts.

-

Improved software integration. Modern laser cutters can integrate with advanced design software for more complex projects.

-

Automation and robotics. Some laser cutters are now equipped with robotic arms for automated material handling.

-

Portable laser cutters. Smaller, portable models are becoming available, making laser cutting accessible for more users.

-

Eco-friendly options. Newer machines are designed to be more energy-efficient and produce fewer emissions.

Fun Facts About Laser Cutters/Engravers

Laser cutters and engravers have some interesting and fun aspects that might surprise you.

-

Laser stands for "Light Amplification by Stimulated Emission of Radiation." This acronym describes the process of creating the focused light beam used in laser cutters.

-

First laser was invented in 1960. The technology has come a long way since then, becoming more accessible and versatile.

-

Laser cutters can create 3D models. By cutting and assembling multiple layers, laser cutters can be used to create three-dimensional objects.

Final Thoughts on Laser Cutters and Engravers

Laser cutters and engravers have revolutionized how we create and design. From intricate jewelry to detailed architectural models, these machines offer precision and versatility. They’re not just for professionals; hobbyists and DIY enthusiasts find them invaluable too. Safety is crucial, so always follow guidelines and use proper ventilation. Maintenance is key to longevity, so keep your machine clean and check for wear and tear. The technology continues to evolve, making these tools more accessible and efficient. Whether you’re a seasoned pro or a curious beginner, there’s a laser cutter or engraver out there for you. Dive in, experiment, and see what amazing creations you can bring to life. With the right machine and a bit of creativity, the possibilities are endless. Happy cutting and engraving!

Was this page helpful?

Our commitment to delivering trustworthy and engaging content is at the heart of what we do. Each fact on our site is contributed by real users like you, bringing a wealth of diverse insights and information. To ensure the highest standards of accuracy and reliability, our dedicated editors meticulously review each submission. This process guarantees that the facts we share are not only fascinating but also credible. Trust in our commitment to quality and authenticity as you explore and learn with us.