What is a wire feeder? A wire feeder is a device used in welding that automatically feeds a continuous wire electrode into the weld pool. This tool ensures a steady supply of filler material, making the welding process more efficient and consistent. Wire feeders are essential in various welding methods, including MIG (Metal Inert Gas) and flux-cored arc welding. They come in different types, such as push, pull, and push-pull systems, each suited for specific applications. Understanding how a wire feeder works can significantly improve welding quality and productivity. Whether you're a professional welder or a hobbyist, knowing the ins and outs of this device can make a big difference in your projects.

What is a Wire Feeder?

A wire feeder is a crucial component in welding systems. It feeds the welding wire to the welding gun, ensuring a smooth and continuous welding process. Here are some fascinating facts about wire feeders:

- Wire feeders are essential for MIG (Metal Inert Gas) and flux-cored arc welding.

- They help maintain a consistent wire speed, which is vital for producing high-quality welds.

- Some wire feeders are portable, making them ideal for fieldwork.

- Advanced models can adjust wire speed automatically based on the welding conditions.

- They come in various sizes and capacities to suit different welding needs.

Types of Wire Feeders

Wire feeders come in different types, each designed for specific applications and welding processes. Understanding these types can help you choose the right one for your needs.

- Push-Pull Wire Feeders: These feeders have a motor in both the feeder and the gun, providing better control over the wire.

- Spool Gun Wire Feeders: Ideal for aluminum welding, these feeders have a small spool of wire attached directly to the gun.

- Bench-Top Wire Feeders: These are stationary units typically used in industrial settings.

- Portable Wire Feeders: Lightweight and easy to carry, these feeders are perfect for on-site welding jobs.

- Boom-Mounted Wire Feeders: These feeders are mounted on a boom arm, allowing for greater flexibility and reach.

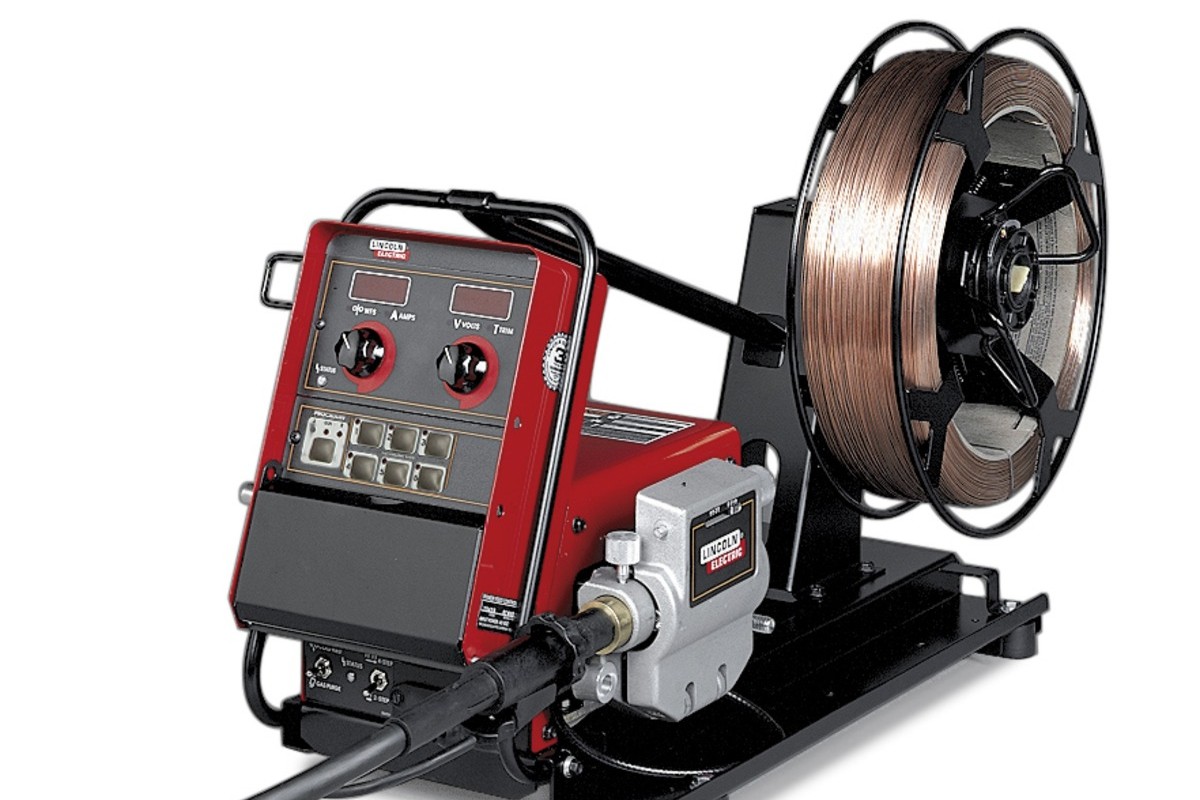

Key Components of a Wire Feeder

Wire feeders consist of several key components that work together to ensure efficient wire feeding. Each component plays a vital role in the overall functionality of the feeder.

- Drive Rolls: These rolls grip and push the wire through the feeder.

- Wire Guides: These guide the wire from the spool to the drive rolls.

- Control Panel: Allows the operator to adjust settings like wire speed and voltage.

- Spool Holder: Holds the wire spool in place.

- Power Source: Supplies the necessary power to the feeder and welding gun.

Benefits of Using a Wire Feeder

Using a wire feeder in welding offers numerous benefits, making the welding process more efficient and effective.

- Increased Productivity: Continuous wire feeding reduces downtime and increases welding speed.

- Consistent Quality: Maintains a steady wire speed, resulting in uniform welds.

- Reduced Operator Fatigue: Automatic feeding reduces the physical strain on the operator.

- Versatility: Suitable for various welding applications and materials.

- Improved Safety: Minimizes the risk of wire tangling and other hazards.

Maintenance Tips for Wire Feeders

Proper maintenance of wire feeders is essential to ensure their longevity and optimal performance. Regular checks and upkeep can prevent common issues.

- Clean Drive Rolls: Regularly clean the drive rolls to prevent wire slippage.

- Inspect Wire Guides: Check for wear and tear and replace if necessary.

- Lubricate Moving Parts: Keep moving parts well-lubricated to ensure smooth operation.

- Check Electrical Connections: Ensure all connections are secure and free of corrosion.

- Replace Worn Components: Timely replacement of worn-out parts can prevent breakdowns.

Common Issues with Wire Feeders

Despite their reliability, wire feeders can encounter issues that affect their performance. Knowing these common problems can help you troubleshoot effectively.

- Wire Jamming: Often caused by improper wire tension or dirty drive rolls.

- Inconsistent Wire Speed: Can result from worn drive rolls or electrical issues.

- Burnback: Occurs when the wire melts back into the contact tip, usually due to incorrect settings.

- Birdnesting: When the wire tangles inside the feeder, often due to incorrect tension settings.

- Erratic Arc: Can be caused by poor electrical connections or worn contact tips.

Innovations in Wire Feeder Technology

The world of wire feeders is continually evolving, with new technologies enhancing their capabilities and performance.

- Smart Feeders: Equipped with sensors and software to optimize wire feeding automatically.

- Wireless Control: Allows operators to adjust settings remotely, improving convenience and safety.

Final Thoughts on Wire Feeders

Wire feeders play a crucial role in welding, ensuring precision and efficiency. They automate the wire feeding process, making welding smoother and more consistent. Understanding the different types, such as push-pull and spool guns, helps in choosing the right one for specific tasks. Regular maintenance, like cleaning and checking for wear, extends their lifespan and ensures optimal performance. Safety is paramount; always follow guidelines to prevent accidents. Investing in a quality wire feeder can significantly improve welding projects, saving time and reducing material waste. Whether you're a professional welder or a hobbyist, knowing these facts about wire feeders can enhance your welding experience. Keep these tips in mind, and you'll be well on your way to mastering the art of welding with wire feeders.

Was this page helpful?

Our commitment to delivering trustworthy and engaging content is at the heart of what we do. Each fact on our site is contributed by real users like you, bringing a wealth of diverse insights and information. To ensure the highest standards of accuracy and reliability, our dedicated editors meticulously review each submission. This process guarantees that the facts we share are not only fascinating but also credible. Trust in our commitment to quality and authenticity as you explore and learn with us.