What is a Glow Discharge Spectrometer (GDS)? A Glow Discharge Spectrometer (GDS) is a powerful tool used in material science to analyze the composition of solid samples. It works by creating a plasma, or "glow discharge," which excites atoms in the sample, causing them to emit light. This emitted light is then measured to determine the elements present. GDS is particularly useful for analyzing metals, alloys, and coatings. It offers high sensitivity, depth profiling, and the ability to analyze both conductive and non-conductive materials. Whether you're a scientist, engineer, or just curious, understanding GDS can open up a world of material analysis possibilities.

What is a Glow Discharge Spectrometer?

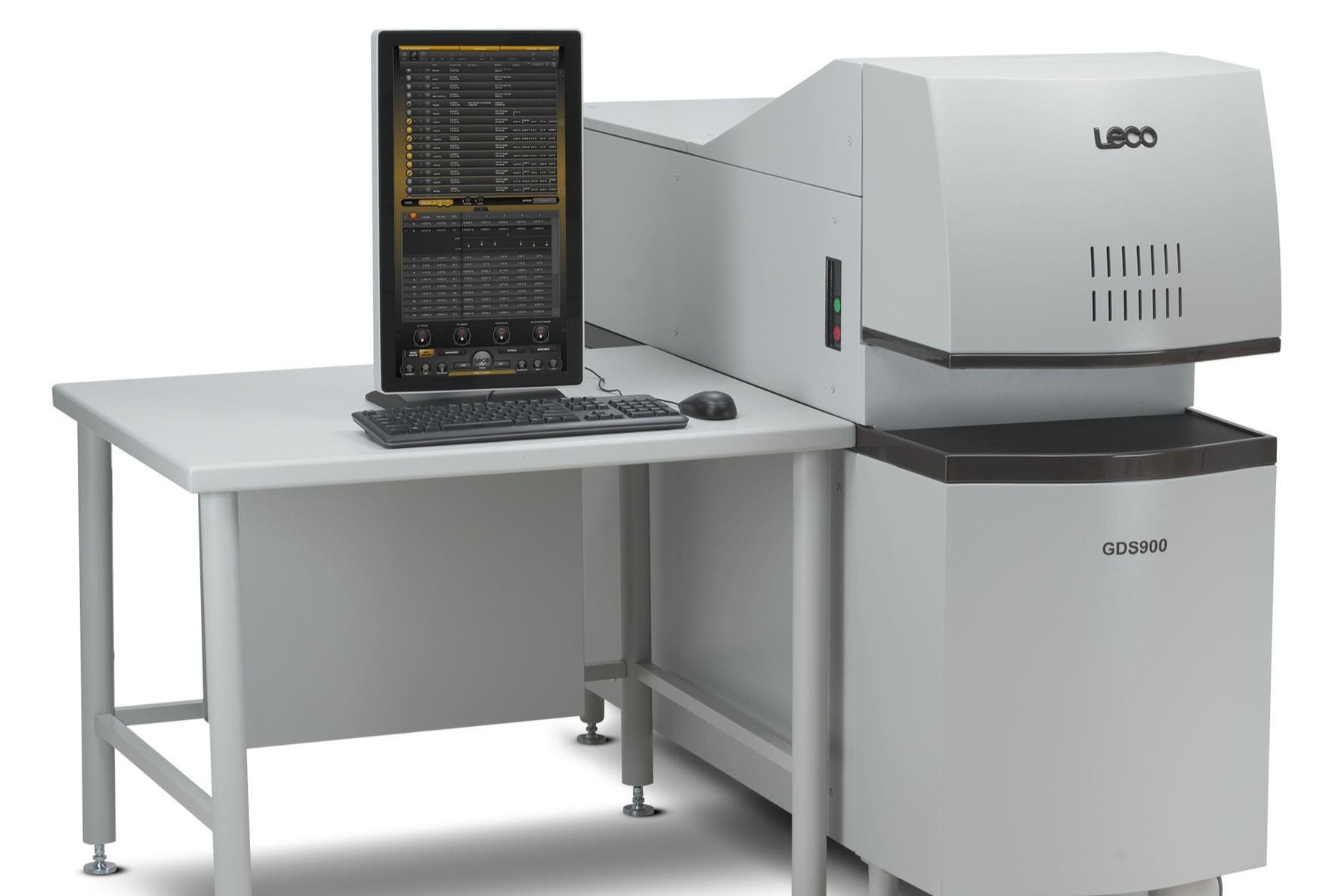

A Glow Discharge Spectrometer (GDS) is a powerful tool used in material analysis. It helps scientists understand the composition of different materials by examining the light emitted from a sample when it is excited by a glow discharge. Let's dive into some fascinating facts about this incredible device.

-

GDS works by applying a high voltage to a sample, causing it to emit light.

When a high voltage is applied, the sample material gets excited and emits light. This light is then analyzed to determine the sample's composition. -

It is commonly used in metallurgy.

Metallurgists use GDS to analyze metals and alloys, ensuring they meet specific standards and properties. -

GDS can analyze both conductive and non-conductive materials.

Unlike some other spectrometers, GDS can handle a wide range of materials, making it versatile. -

The technique is known for its depth profiling capabilities.

GDS can analyze layers of a material, providing detailed information about its composition at different depths.

How Does Glow Discharge Spectrometry Work?

Understanding the working principle of GDS can help appreciate its applications better. Here are some key points about its operation.

-

A glow discharge is created in a low-pressure gas environment.

The sample is placed in a chamber with low-pressure gas, usually argon, to facilitate the glow discharge. -

The sample acts as the cathode.

In the setup, the sample material serves as the cathode, while the chamber walls act as the anode. -

Ions bombard the sample surface.

The glow discharge generates ions that bombard the sample, causing atoms to sputter off the surface. -

Emitted light is analyzed by a spectrometer.

The sputtered atoms emit light, which is then analyzed by the spectrometer to determine the sample's composition.

Applications of Glow Discharge Spectrometry

GDS is used in various fields due to its precise analytical capabilities. Here are some of its applications.

-

Quality control in manufacturing.

Manufacturers use GDS to ensure the quality and consistency of their products. -

Environmental analysis.

GDS helps in analyzing soil and water samples for contamination and pollution levels. -

Research and development.

Scientists use GDS in R&D to develop new materials and improve existing ones. -

Forensic science.

Forensic experts use GDS to analyze evidence and solve crimes.

Advantages of Using Glow Discharge Spectrometry

GDS offers several benefits that make it a preferred choice for material analysis. Here are some advantages.

-

High sensitivity.

GDS can detect even trace amounts of elements in a sample. -

Non-destructive analysis.

The technique does not destroy the sample, allowing for further testing if needed. -

Fast analysis.

GDS provides quick results, making it suitable for high-throughput environments. -

Minimal sample preparation.

Unlike some other techniques, GDS requires little to no sample preparation.

Challenges and Limitations of GDS

Despite its advantages, GDS has some challenges and limitations. Understanding these can help in better application of the technique.

-

High initial cost.

The equipment and setup for GDS can be expensive. -

Requires skilled operators.

Proper operation and interpretation of results require trained personnel. -

Limited to surface analysis.

GDS primarily analyzes the surface and near-surface regions of a sample. -

Interference from other elements.

The presence of certain elements can interfere with the analysis, affecting accuracy.

Innovations and Future of Glow Discharge Spectrometry

The field of GDS is continuously evolving with new innovations. Here are some exciting developments and future prospects.

-

Integration with other techniques.

Combining GDS with other analytical methods can provide more comprehensive results. -

Improved software for data analysis.

Advances in software are making data interpretation faster and more accurate. -

Portable GDS devices.

Development of portable GDS units allows for on-site analysis in various environments. -

Enhanced depth profiling.

New technologies are improving the depth profiling capabilities of GDS.

Interesting Facts About Glow Discharge Spectrometry

Here are some fun and lesser-known facts about GDS that highlight its unique aspects.

-

GDS can analyze thin films.

It is particularly useful for analyzing thin films used in electronics and coatings. -

Used in space missions.

GDS has been used to analyze materials from space missions, providing valuable data about extraterrestrial samples. -

Helps in art restoration.

Art conservators use GDS to analyze and restore historical artifacts and paintings. -

Contributes to semiconductor industry.

The semiconductor industry relies on GDS for quality control and material analysis. -

Supports renewable energy research.

Researchers use GDS to develop and improve materials for solar panels and batteries. -

Aids in medical research.

Medical researchers use GDS to analyze biomaterials and develop new medical devices. -

Used in archaeology.

Archaeologists use GDS to analyze ancient artifacts and understand historical civilizations.

The Final Spark

Glow discharge spectrometry (GDS) is a fascinating tool in material analysis. From its unique ability to analyze thin films to its precision in detecting trace elements, GDS stands out. It’s not just about the science; it’s about the practical applications that make a difference in industries like metallurgy, electronics, and forensics.

Understanding the basics of how GDS works can help you appreciate its importance. The glow discharge process, the sputtering of atoms, and the detection of emitted light all play crucial roles.

Whether you’re a student, a professional, or just curious, knowing these facts can give you a new perspective on material analysis. GDS isn’t just a tool; it’s a gateway to discovering the hidden secrets of materials. Keep these facts in mind, and you’ll see the world of materials in a whole new light.

Was this page helpful?

Our commitment to delivering trustworthy and engaging content is at the heart of what we do. Each fact on our site is contributed by real users like you, bringing a wealth of diverse insights and information. To ensure the highest standards of accuracy and reliability, our dedicated editors meticulously review each submission. This process guarantees that the facts we share are not only fascinating but also credible. Trust in our commitment to quality and authenticity as you explore and learn with us.