What is the Portevin-Le Chatelier effect? The Portevin-Le Chatelier effect, also known as serrated yielding, is a phenomenon observed in certain metals and alloys where the material exhibits jerky or discontinuous flow during plastic deformation. This effect occurs due to dynamic strain aging, where interactions between dislocations and diffusing atoms cause localized strain bands. These bands lead to sudden jumps in stress-strain curves, making the material behave unpredictably under stress. Commonly seen in aluminum, copper, and steel alloys, this effect can impact the mechanical properties and performance of materials in various applications. Understanding this phenomenon is crucial for engineers and materials scientists to predict and mitigate potential issues in manufacturing and structural integrity.

What is the Portevin-Le Chatelier Effect?

The Portevin-Le Chatelier (PLC) effect is a fascinating phenomenon observed in materials science, particularly in metals. It involves a type of plastic instability that occurs during the deformation of certain alloys. This effect is named after French scientists Albert Portevin and François Le Chatelier, who first described it in the early 20th century.

- The PLC effect is also known as serrated yielding or jerky flow.

- It typically occurs in aluminum, magnesium, and copper alloys.

- The effect is most noticeable at specific temperature ranges and strain rates.

How Does the PLC Effect Manifest?

Understanding how the PLC effect manifests can help in predicting and controlling it in industrial applications. Here are some key manifestations:

- The PLC effect causes irregular stress-strain curves during tensile testing.

- It results in localized deformation bands that move through the material.

- These bands are often referred to as Lüders bands or Portevin-Le Chatelier bands.

Why Does the PLC Effect Occur?

The underlying mechanisms of the PLC effect are complex but fascinating. Here's a look at why it happens:

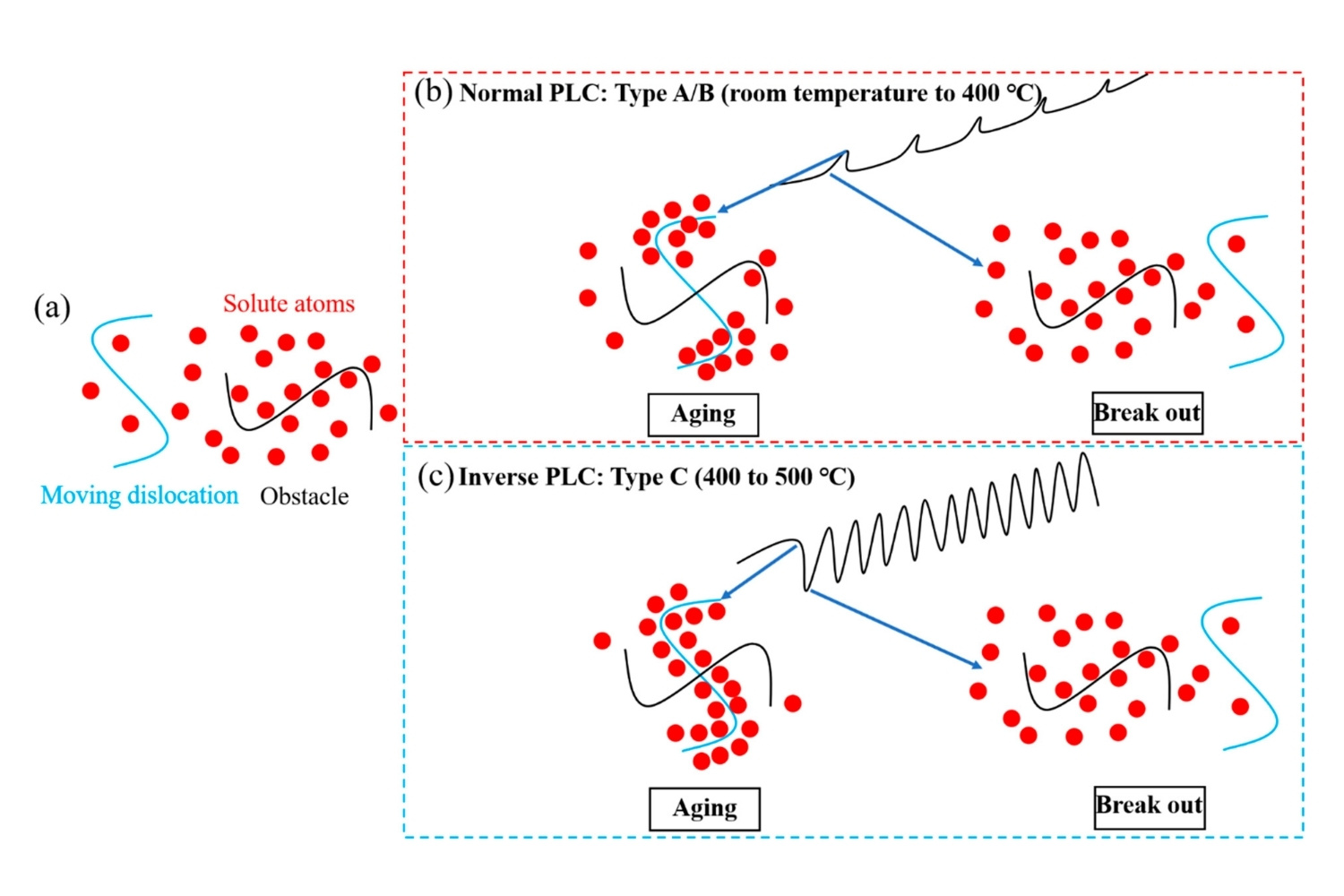

- The effect is caused by the interaction between dislocations and solute atoms.

- Dynamic strain aging is a primary factor contributing to the PLC effect.

- The phenomenon is more likely to occur in materials with high solute atom concentrations.

Impact on Material Properties

The PLC effect can significantly impact the mechanical properties of materials. Understanding these impacts is crucial for engineers and scientists.

- It can lead to reduced ductility in affected materials.

- The effect can cause anomalous hardening during plastic deformation.

- It may result in surface roughness and poor finish in manufactured parts.

Industrial Relevance of the PLC Effect

The PLC effect has several implications for industrial processes, particularly in metal forming and manufacturing.

- It can affect the quality of metal sheets used in automotive and aerospace industries.

- The effect can lead to unexpected failures in structural components.

- Controlling the temperature and strain rate can help mitigate the PLC effect.

Research and Studies on the PLC Effect

Ongoing research aims to better understand and control the PLC effect. Here are some interesting findings from recent studies:

- Advanced microscopy techniques have been used to observe PLC bands in real-time.

- Computer simulations help predict the occurrence of the PLC effect in different materials.

- Studies have shown that alloying elements can influence the severity of the PLC effect.

Historical Context and Discovery

The discovery of the PLC effect has a rich history, rooted in early 20th-century materials science.

- Albert Portevin and François Le Chatelier first described the effect in 1923.

- Their work laid the foundation for modern studies on plastic instability.

- The PLC effect was initially observed in aluminum-copper alloys.

Practical Examples of the PLC Effect

Real-world examples help illustrate the practical implications of the PLC effect.

- The effect is often observed in the cold rolling of aluminum sheets.

- It can occur during the extrusion of magnesium alloys.

- The PLC effect has been noted in the drawing of copper wires.

Mitigating the PLC Effect

Various strategies can be employed to mitigate the PLC effect in industrial applications.

- Heat treatment can reduce the occurrence of the PLC effect.

- Alloying with certain elements can help control the effect.

- Optimizing strain rates during processing can minimize the impact.

Future Directions in PLC Effect Research

The future of PLC effect research holds promise for new discoveries and applications.

- Nanotechnology may offer new ways to control the PLC effect.

- Machine learning could predict the occurrence of the effect with greater accuracy.

- Interdisciplinary research combining materials science and engineering will likely yield new insights.

Lesser-Known Facts About the PLC Effect

Here are some lesser-known but intriguing facts about the PLC effect:

- The effect can also occur in polycrystalline materials.

- Environmental factors like humidity can influence the PLC effect.

- The effect has been observed in biomaterials like bone.

Challenges in Studying the PLC Effect

Studying the PLC effect presents several challenges that researchers must overcome.

- Capturing real-time data during deformation is difficult.

- Isolating variables that contribute to the effect can be complex.

- Replicating conditions in laboratory settings to study the effect accurately is challenging.

Final Thoughts on the Portevin-Le Chatelier Effect

The Portevin-Le Chatelier effect is a fascinating phenomenon in materials science. It highlights how materials can behave unpredictably under certain conditions. This effect, often seen in metals like aluminum and steel, can cause sudden jerks or jumps in the material's deformation. Understanding this effect is crucial for industries relying on these metals, as it can impact the safety and performance of structures.

Researchers continue to study the Portevin-Le Chatelier effect to better predict and control it. By doing so, they aim to improve the reliability of materials used in construction, automotive, and aerospace industries. This ongoing research not only enhances our knowledge of material behavior but also contributes to the development of safer, more efficient technologies.

So, the next time you see a metal structure, remember the complex science ensuring its stability and performance. The Portevin-Le Chatelier effect is just one piece of that puzzle.

Was this page helpful?

Our commitment to delivering trustworthy and engaging content is at the heart of what we do. Each fact on our site is contributed by real users like you, bringing a wealth of diverse insights and information. To ensure the highest standards of accuracy and reliability, our dedicated editors meticulously review each submission. This process guarantees that the facts we share are not only fascinating but also credible. Trust in our commitment to quality and authenticity as you explore and learn with us.